Alloy

An alloy is a

, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength.In an alloy, the atoms are joined by

Examples of alloys include

Alloys are used in a wide variety of applications, from the steel alloys, used in everything from buildings to automobiles to surgical tools, to exotic titanium alloys used in the aerospace industry, to beryllium-copper alloys for non-sparking tools.

Characteristics

An alloy is a mixture of chemical elements, which forms an impure substance (admixture) that retains the characteristics of a metal. An alloy is distinct from an impure metal in that, with an alloy, the added elements are well controlled to produce desirable properties, while impure metals such as wrought iron are less controlled, but are often considered useful. Alloys are made by mixing two or more elements, at least one of which is a metal. This is usually called the primary metal or the base metal, and the name of this metal may also be the name of the alloy. The other constituents may or may not be metals but, when mixed with the molten base, they will be soluble and dissolve into the mixture. The mechanical properties of alloys will often be quite different from those of its individual constituents. A metal that is normally very soft (

Like oil and water, a molten metal may not always mix with another element. For example, pure iron is almost completely

Some alloys, such as

An alloy is technically an impure metal, but when referring to alloys, the term impurities usually denotes undesirable elements. Such impurities are introduced from the base metals and alloying elements, but are removed during processing. For instance, sulfur is a common impurity in steel. Sulfur combines readily with iron to form

Theory

Alloying a metal is done by combining it with one or more other elements. The most common and oldest alloying process is performed by heating the base metal beyond its

By adding another element to a metal, differences in the size of the atoms create internal stresses in the lattice of the metallic crystals; stresses that often enhance its properties. For example, the combination of carbon with iron produces steel, which is stronger than iron, its primary element. The

Unlike pure metals, most alloys do not have a single

Heat treatment

Alloying elements are added to a base metal, to induce

The base metal iron of the iron-carbon alloy known as steel, undergoes a change in the arrangement (

While the high strength of steel results when diffusion and precipitation is prevented (forming martensite), most heat-treatable alloys are precipitation hardening alloys, that depend on the diffusion of alloying elements to achieve their strength. When heated to form a solution and then cooled quickly, these alloys become much softer than normal, during the diffusionless transformation, but then harden as they age. The solutes in these alloys will precipitate over time, forming intermetallic phases, which are difficult to discern from the base metal. Unlike steel, in which the solid solution separates into different crystal phases (carbide and ferrite), precipitation hardening alloys form different phases within the same crystal. These intermetallic alloys appear homogeneous in crystal structure, but tend to behave heterogeneously, becoming hard and somewhat brittle.[8]

In 1906, precipitation hardening alloys were discovered by Alfred Wilm. Precipitation hardening alloys, such as certain alloys of aluminium, titanium, and copper, are heat-treatable alloys that soften when quenched (cooled quickly), and then harden over time. Wilm had been searching for a way to harden aluminium alloys for use in machine-gun cartridge cases. Knowing that aluminium-copper alloys were heat-treatable to some degree, Wilm tried quenching a ternary alloy of aluminium, copper, and the addition of magnesium, but was initially disappointed with the results. However, when Wilm retested it the next day he discovered that the alloy increased in hardness when left to age at room temperature, and far exceeded his expectations. Although an explanation for the phenomenon was not provided until 1919, duralumin was one of the first "age hardening" alloys used, becoming the primary building material for the first Zeppelins, and was soon followed by many others.[9] Because they often exhibit a combination of high strength and low weight, these alloys became widely used in many forms of industry, including the construction of modern aircraft.[10]

Mechanisms

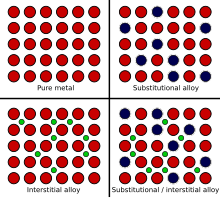

When a molten metal is mixed with another substance, there are two mechanisms that can cause an alloy to form, called atom exchange and the interstitial mechanism. The relative size of each element in the mix plays a primary role in determining which mechanism will occur. When the atoms are relatively similar in size, the atom exchange method usually happens, where some of the atoms composing the metallic crystals are substituted with atoms of the other constituent. This is called a substitutional alloy. Examples of substitutional alloys include bronze and brass, in which some of the copper atoms are substituted with either tin or zinc atoms respectively.

In the case of the interstitial mechanism, one atom is usually much smaller than the other and can not successfully substitute for the other type of atom in the crystals of the base metal. Instead, the smaller atoms become trapped in the interstitial sites between the atoms of the crystal matrix. This is referred to as an interstitial alloy. Steel is an example of an interstitial alloy, because the very small carbon atoms fit into interstices of the iron matrix.

Stainless steel is an example of a combination of interstitial and substitutional alloys, because the carbon atoms fit into the interstices, but some of the iron atoms are substituted by nickel and chromium atoms.[8]

History and examples

Meteoric iron

The use of alloys by humans started with the use of meteoric iron, a naturally occurring alloy of nickel and iron. It is the main constituent of iron meteorites. As no metallurgic processes were used to separate iron from nickel, the alloy was used as it was.[11] Meteoric iron could be forged from a red heat to make objects such as tools, weapons, and nails. In many cultures it was shaped by cold hammering into knives and arrowheads. They were often used as anvils. Meteoric iron was very rare and valuable, and difficult for ancient people to work.[12]

Bronze and brass

Iron is usually found as

Amalgams

Precious metals

Many ancient civilizations alloyed metals for purely aesthetic purposes. In ancient Egypt and Mycenae, gold was often alloyed with copper to produce red-gold, or iron to produce a bright burgundy-gold. Gold was often found alloyed with silver or other metals to produce various types of colored gold. These metals were also used to strengthen each other, for more practical purposes. Copper was often added to silver to make sterling silver, increasing its strength for use in dishes, silverware, and other practical items. Quite often, precious metals were alloyed with less valuable substances as a means to deceive buyers.[19] Around 250 BC, Archimedes was commissioned by the King of Syracuse to find a way to check the purity of the gold in a crown, leading to the famous bath-house shouting of "Eureka!" upon the discovery of Archimedes' principle.[20]

Pewter

The term pewter covers a variety of alloys consisting primarily of tin. As a pure metal, tin is much too soft to use for most practical purposes. However, during the Bronze Age, tin was a rare metal in many parts of Europe and the Mediterranean, so it was often valued higher than gold. To make jewellery, cutlery, or other objects from tin, workers usually alloyed it with other metals to increase strength and hardness. These metals were typically lead, antimony, bismuth or copper. These solutes were sometimes added individually in varying amounts, or added together, making a wide variety of objects, ranging from practical items such as dishes, surgical tools, candlesticks or funnels, to decorative items like ear rings and hair clips.

The earliest examples of pewter come from ancient Egypt, around 1450 BC. The use of pewter was widespread across Europe, from France to Norway and Britain (where most of the ancient tin was mined) to the Near East.[21] The alloy was also used in China and the Far East, arriving in Japan around 800 AD, where it was used for making objects like ceremonial vessels, tea canisters, or chalices used in shinto shrines.[22]

Iron

The first known smelting of iron began in

While the use of iron started to become more widespread around 1200 BC, mainly because of interruptions in the trade routes for tin, the metal was much softer than bronze. However, very small amounts of steel, (an alloy of iron and around 1% carbon), was always a byproduct of the bloomery process. The ability to modify the hardness of steel by heat treatment had been known since 1100 BC, and the rare material was valued for the manufacture of tools and weapons. Because the ancients could not produce temperatures high enough to melt iron fully, the production of steel in decent quantities did not occur until the introduction of

The introduction of the blast furnace to Europe in the Middle Ages meant that people could produce pig iron in much higher volumes than wrought iron. Because pig iron could be melted, people began to develop processes to reduce carbon in liquid pig iron to create steel.

Steel is an alloy of iron and carbon, but the term alloy steel usually only refers to steels that contain other elements— like vanadium, molybdenum, or cobalt—in amounts sufficient to alter the properties of the base steel. Since ancient times, when steel was used primarily for tools and weapons, the methods of producing and working the metal were often closely guarded secrets. Even long after the Age of Enlightenment, the steel industry was very competitive and manufacturers went through great lengths to keep their processes confidential, resisting any attempts to scientifically analyze the material for fear it would reveal their methods. For example, the people of Sheffield, a center of steel production in England, were known to routinely bar visitors and tourists from entering town to deter industrial espionage. Thus, almost no metallurgical information existed about steel until 1860. Because of this lack of understanding, steel was not generally considered an alloy until the decades between 1930 and 1970 (primarily due to the work of scientists like William Chandler Roberts-Austen, Adolf Martens, and Edgar Bain), so "alloy steel" became the popular term for ternary and quaternary steel-alloys.[24][25]

After Benjamin Huntsman developed his crucible steel in 1740, he began experimenting with the addition of elements like manganese (in the form of a high-manganese pig-iron called spiegeleisen), which helped remove impurities such as phosphorus and oxygen; a process adopted by Bessemer and still used in modern steels (albeit in concentrations low enough to still be considered carbon steel).[26] Afterward, many people began experimenting with various alloys of steel without much success. However, in 1882, Robert Hadfield, being a pioneer in steel metallurgy, took an interest and produced a steel alloy containing around 12% manganese. Called mangalloy, it exhibited extreme hardness and toughness, becoming the first commercially viable alloy-steel.[27] Afterward, he created silicon steel, launching the search for other possible alloys of steel.[28]

Others

Due to their high reactivity, most metals were not discovered until the 19th century. A method for extracting aluminium from bauxite was proposed by Humphry Davy in 1807, using an electric arc. Although his attempts were unsuccessful, by 1855 the first sales of pure aluminium reached the market. However, as extractive metallurgy was still in its infancy, most aluminium extraction-processes produced unintended alloys contaminated with other elements found in the ore; the most abundant of which was copper. These aluminium-copper alloys (at the time termed "aluminum bronze") preceded pure aluminium, offering greater strength and hardness over the soft, pure metal, and to a slight degree were found to be heat treatable.[32] However, due to their softness and limited hardenability these alloys found little practical use, and were more of a novelty, until the Wright brothers used an aluminium alloy to construct the first airplane engine in 1903.[30] During the time between 1865 and 1910, processes for extracting many other metals were discovered, such as chromium, vanadium, tungsten, iridium, cobalt, and molybdenum, and various alloys were developed.[33]

Prior to 1910, research mainly consisted of private individuals tinkering in their own laboratories. However, as the aircraft and automotive industries began growing, research into alloys became an industrial effort in the years following 1910, as new

See also

- Alloy broadening

- CALPHAD

- Ideal mixture

- List of alloys

References

- ^ Callister, W.D. "Materials Science and Engineering: An Introduction" 2007, 7th edition, John Wiley and Sons, Inc. New York, Section 4.3 and Chapter 9.

- ISBN 978-1-61503-056-9. Archivedfrom the original on 2016-05-05.

- ISBN 978-0-87170-496-2.

- ^ Metals Handbook: Properties and selection By ASM International – ASM International 1978 Page 407

- ^ Mills, Adelbert Phillo (1922) Materials of Construction: Their Manufacture and Properties, John Wiley & sons, inc, originally published by the University of Wisconsin, Madison

- .

- PMID 9896377.

- ^ ISBN 1-61503-110-3.

- ^ Metallurgy for the Non-Metallurgist by Harry Chandler – ASM International 1998 Page 1—3

- ^ Jacobs, M.H. Precipitation Hardnening Archived 2012-12-02 at the Wayback Machine. University of Birmingham. TALAT Lecture 1204. slideshare.net

- JSTOR 2844401.

- ^ Buchwald, pp. 13–22

- ^ Buchwald, pp. 35–37

- ^ Buchwald, pp. 39–41

- ^ ISBN 0-262-69120-5.

- ^ Emperor's Ghost Army Archived 2017-11-01 at the Wayback Machine. pbs.org. November 2014

- ISBN 3-540-78593-0

- ISBN 0-521-29208-5.

- ISBN 0-521-45257-0.

- ISBN 0-415-35115-4.

- ISBN 0-7478-0152-5

- ^ Brinkley, Frank (1904) Japan and China: Japan, its history, arts, and literature. Oxford University. p. 317

- ^ ISBN 0-87170-599-0.

- ^ Sheffield Steel and America: A Century of Commercial and Technological Independence By Geoffrey Tweedale – Cambridge University Press 1987 Page 57—62

- ^ Experimental Techniques in Materials and Mechanics By C. Suryanarayana – CRC Press 2011 p. 202

- ^ Tool Steels, 5th Edition By George Adam Roberts, Richard Kennedy, G. Krauss – ASM International 1998 p. 4

- ISBN 978-1-61503-146-7. Archivedfrom the original on 2016-05-02.

- ^ Sheffield Steel and America: A Century of Commercial and Technological Independence By Geoffrey Tweedale – Cambridge University Press 1987 pp. 57—62

- ^ Sheffield Steel and America: A Century of Commercial and Technological Independence By Geoffrey Tweedale – Cambridge University Press 1987 pp. 66—68

- ^ a b c Metallurgy for the Non-Metallurgist by Harry Chandler – ASM International 1998 Page 3—5

- ^ Sheffield Steel and America: A Century of Commercial and Technological Independence By Geoffrey Tweedale – Cambridge University Press 1987 p. 75

- ^ Aluminium: Its History, Occurrence, Properties, Metallurgy and Applications by Joseph William Richards – Henry Cairy Baird & Co 1887 Page 25—42

- ^ Metallurgy: 1863–1963 by W.H. Dennis – Routledge 2017

Bibliography

- Buchwald, Vagn Fabritius (2005). Iron and steel in ancient times. Det Kongelige Danske Videnskabernes Selskab. ISBN 978-87-7304-308-0.

External links

- Roberts-Austen, William Chandler; Neville, Francis Henry (1911). . Encyclopædia Britannica (11th ed.).

- . The American Cyclopædia. 1879.