Aluminium hydride

| |

| Names | |

|---|---|

| Preferred IUPAC name

Aluminium hydride | |

| Systematic IUPAC name

Alumane | |

Other names

| |

| Identifiers | |

3D model (

JSmol ) |

|

| ChEBI | |

| ChemSpider | |

ECHA InfoCard

|

100.029.139 |

| 245 | |

PubChem CID

|

|

| UNII | |

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| AlH3 | |

| Molar mass | 30.006 g·mol−1 |

| Appearance | white crystalline solid, non-volatile, highly polymerized, needle-like crystals |

| Density | 1.477 g/cm3, solid |

| Melting point | 150 °C (302 °F; 423 K) starts decomposing at 105 °C (221 °F) |

| reacts | |

| Solubility | soluble in ether reacts in ethanol |

| Thermochemistry | |

Heat capacity (C)

|

40.2 J/(mol·K) |

Std molar

entropy (S⦵298) |

30 J/(mol·K) |

Std enthalpy of (ΔfH⦵298)formation |

−11.4 kJ/mol |

Gibbs free energy (ΔfG⦵)

|

46.4 kJ/mol |

| Related compounds | |

Related compounds

|

Lithium aluminium hydride, diborane |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Aluminium hydride (also known as alane and alumane) is an

Solid aluminium hydride, or alane, is colorless and nonvolatile, and in its most common reagent form it is a highly

Form and structure

This section needs additional citations for verification. (July 2022) |

Alane is a colorless and nonvolatile solid that melts with decomposition at 110 °C.[4] The solid form, however, often presents as a white solid that may be tinted grey (with decreasing reagent particle size or increasing impurity levels).[citation needed] This coloration arises from a thin surface passivation layer of aluminium oxide or hydroxide.[citation needed]

Under common laboratory conditions, alane is "highly polymeric", structurally.[4] This is sometimes indicated with the formula (AlH3)n, where n is left unspecified.[5][non-primary source needed] Preparations of alane dissolve in tetrahydrofuran (THF) or diethyl ether (ether),[4] from which pure allotropes precipitate.[6][non-primary source needed]

Structurally, alane can adopt numerous

| Crystallographic Structure of α-AlH3[8] | |||||

|---|---|---|---|---|---|

| The α-AlH3 unit cell | Aluminium coordination | Hydrogen coordination | |||

|

|

| |||

When β- and γ-alanes are produced together, they convert to α-alane upon heating, while δ-, ε-, and θ-alanes are produced in still other crystallization conditions; although they are less thermally stable, the δ-, ε-, and θ-alane polymorphs do not convert to α-alane upon heating.

Under special conditions, non-polymeric alanes (i.e., molecular forms of it) can be prepared and studied. Monomeric AlH3 has been isolated at low temperature in a solid noble gas matrix where it was shown to be planar.[9] The dimeric form, Al2H6, has been isolated in solid hydrogen, and it is isostructural with diborane (B2H6) and digallane (Ga2H6).[10][11][non-primary source needed]

Handling

Alane is not spontaneously flammable.

Passivation[clarification needed] greatly diminishes the decomposition rate associated with alane preparations.[citation needed] Passivated alane nevertheless retains a hazard classification of 4.3 (chemicals which in contact with water, emit flammable gases).[14]

Reported accidents

This section needs expansion with: a careful, source-derived presentation of accidents known to be associated with use of this agent, at small and large scale. You can help by adding to it. (July 2022) |

Alane reductions are believed to proceed via an intermediate

Preparation

Aluminium hydrides and various complexes thereof have long been known.

- 3 Li[AlH4] + AlCl3 → 4 AlH3 + 3 LiCl

The ether solution of alane requires immediate use, because polymeric material rapidly precipitates as a solid. Aluminium hydride solutions are known to degrade after 3 days. Aluminium hydride is more reactive than Li[AlH4].[6]

Several other methods exist for the preparation of aluminium hydride:

- 2 Li[AlH4] + BeCl2 → 2 AlH3 + Li2[BeH2Cl2]

- 2 Li[AlH4] + H2SO4 → 2 AlH3 + Li2SO4 + 2 H2

- 2 Li[AlH4] + ZnCl2 → 2 AlH3 + 2 LiCl + ZnH2

- 2 Li[AlH4] + I2 → 2 AlH3 + 2 LiI + H2

Electrochemical synthesis

Several groups have shown that alane can be produced electrochemically.[20][21][22][23][24] Different electrochemical alane production methods have been patented.[25][26] Electrochemically generating alane avoids chloride impurities. Two possible mechanisms are discussed for the formation of alane in Clasen's electrochemical cell containing THF as the solvent, sodium aluminium hydride as the electrolyte, an aluminium anode, and an iron (Fe) wire submerged in mercury (Hg) as the cathode. The sodium forms an amalgam with the Hg cathode preventing side reactions and the hydrogen produced in the first reaction could be captured and reacted back with the sodium mercury amalgam to produce sodium hydride. Clasen's system results in no loss of starting material. For insoluble anodes, reaction 1 occurs, while for soluble anodes, anodic dissolution is expected according to reaction 2:

- [AlH4]− − e− + n THF → AlH3·nTHF + 1/2 H2

- 3 [AlH4]− + Al − 3 e− + 4n THF → 4 AlH3·nTHF

In reaction 2, the aluminium anode is consumed, limiting the production of aluminium hydride for a given electrochemical cell.

The crystallization and recovery of aluminium hydride from electrochemically generated alane has been demonstrated.[23][24]

High pressure hydrogenation of aluminium

α-AlH3 can be produced by hydrogenation of aluminium at 10

Reactions

Formation of adducts with Lewis bases

AlH3 readily forms adducts with strong

Its complex with diethyl ether forms according to the following stoichiometry:

- AlH3 + (CH3CH2)2O → (CH3CH2)2O·AlH3

The reaction with lithium hydride in ether produces lithium aluminium hydride:

- AlH3 + LiH → Li[AlH4]

Reduction of functional groups

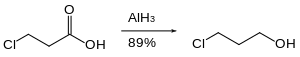

In organic chemistry, aluminium hydride is mainly used for the reduction of functional groups..

In terms of functional group selectivity, alane differs from other hydride reagents. For example, in the following cyclohexanone reduction, lithium aluminium hydride gives a trans:cis ratio of 1.9 : 1, whereas aluminium hydride gives a trans:cis ratio of 7.3 : 1.[32]

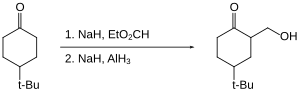

Alane enables the hydroxymethylation of certain ketones (that is the replacement of C−H by C−CH2OH at the

Aluminium hydride can be used in the reduction of acetals to half protected diols.[36]

Aluminium hydride can also be used in epoxide ring opening reaction as shown below.[37]

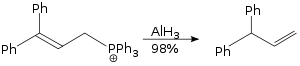

The allylic rearrangement reaction carried out using aluminium hydride is a SN2 reaction, and it is not sterically demanding.[38]

Aluminium hydride will reduce carbon dioxide to methane with heating:[citation needed]

- 4 AlH3 + 3 CO2 → 3 CH4 + 2 Al2O3

Hydroalumination

This section needs expansion. You can help by adding to it. (July 2022) |

Akin to

Fuel

This section needs to be updated. (July 2022) |

In its passivated form, alane is an active candidate for storing hydrogen, and can be used for efficient power generation via fuel cell applications, including fuel cell and electric vehicles and other lightweight power applications.[citation needed] AlH3 contains up 10.1% hydrogen by weight (at a density of 1.48 grams per milliliter),[2] or twice the hydrogen density of liquid H2.[citation needed] As of 2006, AlH3 was being described as a candidate for which "further research w[ould] be required to develop an efficient and economical process to regenerate [it] from the spent Al powder".[2][needs update]

Allane is also a potential additive to

References

- .

- ^ OSTI 899889. Retrieved 28 July 2022.

- PMID 27535100.

- ^ ISBN 978-0471936237. Retrieved 28 July 2022.

- ^ See, e.g., Andrews & Wang 2003.

- ^ a b c US application 2007066839, Lund, G. K.; Hanks, J. M.; Johnston, H. E., "Method for the Production of α-Alane."

- ^ Turley & Rinn 1969. (Abstract) "The final Al⋯H distance of 1.72 Å, the participation of each Al in six bridges, and the equivalence of all Al⋯H distances suggest that 3c-2e bonding occurs." Angle is lasted as "Al(6)-H(5)-Al(4)" in Table IV.

- .

- . (Abstract) Broad-band photolysis of a solid noble gas matrix containing Al atoms and H2 gives rise to the planar, monomeric AlH3 molecule.

- .

- .

- ^ Galatsis, Sintim & Wang 2008, which describes the phenomenon using the synonym "inflammable".

- ^ ISBN 0471936235. Retrieved 28 July 2022.

- ^ 2013 CFR Title 29 Volume 6 Section 1900.1200 Appendix B.12

- S2CID 225542103.

- .

- .

- ^ US patent 6228338, Petrie, M. A.; Bottaro, J. C.; Schmitt, R. J.; Penwell, P. E.; Bomberger, D. C., "Preparation of Aluminum Hydride Polymorphs, Particularly Stabilized α-AlH3", issued 2001-05-08

- ISBN 9780470132456.

- S2CID 250839118.

- S2CID 250889877.

- ^ Osipov, O. R.; Alpatova, N. M.; Kessler, Yu. M. (1966). Elektrokhimiya. 2: 984.

{{cite journal}}: CS1 maint: untitled periodical (link) - ^ S2CID 21479330.

- ^ S2CID 93879202.

- ^ DE patent 1141623, Clasen, H., "Verfahren zur Herstellung von Aluminiumhydrid bzw. aluminiumwasserstoffreicher komplexer Hydride", issued 1962-12-27, assigned to Metallgesellschaft

- ^ US patent 8470156, Zidan, R., "Electrochemical process and production of novel complex hydrides", issued 2013-06-25, assigned to Savannah River Nuclear Solutions, LLC

- ISSN 1742-6596.

- ^ ISBN 978-0-08-037941-8.

- .

- .

- ISBN 978-0-470-84289-8.

- .

- .

- .

- ]

- .

- S2CID 196795254.

- .

- .

- ^ Smith (2020), March's Advanced Organic Chemistry, rxn. 15-12.

- .

- ISBN 978-2-7598-0673-7.

External links

- Aluminium Hydride on EnvironmentalChemistry.com Chemical Database

- Hydrogen Storage from Brookhaven National Laboratory

- Aluminum Trihydride on WebElements