Brine

| Part of a series on |

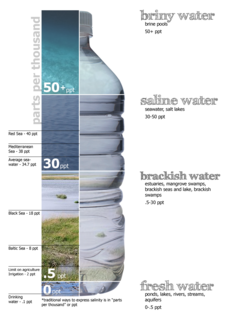

| Water salinity |

|---|

|

| Salinity levels |

|

Fresh water (< 0.05%) Brackish water (0.05–3%) Saline water (3–5%) Brine (> 5% up to 26%–28% max) |

| Bodies of water |

Brine (or briny water) is

In nature

Brines are produced in multiple ways in nature. Modification of seawater via evaporation results in the concentration of salts in the residual fluid, a characteristic geologic deposit called an evaporite is formed as different dissolved ions reach the saturation states of minerals, typically gypsum and halite. Dissolution of such salt deposits into water can produce brines as well. As seawater freezes, dissolved ions tend to remain in solution resulting in a fluid termed a cryogenic brine. At the time of formation, these cryogenic brines are by definition cooler than the freezing temperature of seawater and can produce a feature called a brinicle where cool brines descend, freezing the surrounding seawater.

The brine cropping out at the surface as saltwater springs are known as "licks" or "salines".

Uses

Culinary

Brine is a common agent in food processing and cooking. Brining is used to preserve or season the food. Brining can be applied to vegetables, cheeses, fruit and some fish in a process known as pickling. Meat and fish are typically steeped in brine for shorter periods of time, as a form of marination, enhancing its tenderness and flavor, or to enhance shelf period.

Chlorine production

Elemental chlorine can be produced by

- Cathode: 2 H+ + 2 e− → H2 ↑

- Anode: 2 Cl− → Cl2 ↑ + 2 e−

- Overall process: 2 NaCl + 2 H2O → Cl2 + H2 + 2 NaOH

Refrigerating fluid

Brine is used as a secondary

Because of their corrosive properties salt-based brines have been replaced by organic liquids such as ethylene glycol.[6]

Sodium chloride brine spray is used on some fishing vessels to freeze fish.[7] The brine temperature is generally −5 °F (−21 °C). Air blast freezing temperatures are −31 °F (−35 °C) or lower. Given the higher temperature of brine, the system efficiency over air blast freezing can be higher. High-value fish usually are frozen at much lower temperatures, below the practical temperature limit for brine.

Water softening and purification

Brine is an auxiliary agent in water softening and water purification systems involving ion exchange technology. The most common example are household dishwashers, utilizing sodium chloride in form of dishwasher salt. Brine is not involved in the purification process itself, but used for regeneration of ion-exchange resin on cyclical basis. The water being treated flows through the resin container until the resin is considered exhausted and water is purified to a desired level. Resin is then regenerated by sequentially backwashing the resin bed to remove accumulated solids, flushing removed ions from the resin with a concentrated solution of replacement ions, and rinsing the flushing solution from the resin.[8] After treatment, ion-exchange resin beads saturated with calcium and magnesium ions from the treated water, are regenerated by soaking in brine containing 6–12% NaCl. The sodium ions from brine replace the calcium and magnesium ions on the beads.[9][10]

De-icing

In lower temperatures, a brine solution can be used to

Quenching

Quenching is a heat-treatment process when forging metals such as steel. A brine solution, along with oil and other substances, is commonly used to harden steel. When brine is used, there is an enhanced uniformity of the cooling process and heat transfer.[12]

Desalination

The desalination process consists of the separation of salts from an aqueous solution to obtain fresh water from a source of seawater or brackish water; and in turn, a discharge is generated, commonly called brine.[13]

Characteristics

The characteristics of the discharge depend on different factors, such as the desalination technology used, salinity and quality of the water used, environmental and oceanographic characteristics, desalination process carried out, among others.[14] The discharge of desalination plants by seawater reverse osmosis (SWRO), are mainly characterized by presenting a salinity concentration that can, in the worst case, double the salinity of the seawater used, and unlike of thermal desalination plants, have practically the same temperature and dissolved oxygen as the seawater used.[15][16]

Dissolved chemicals

The discharge could contain trace chemical products used during the industrial treatments applies,such as antiscalants[17], , coagulants, flocculantswhich are discarded together with the discharge, and which could affect the physical-chemical quality of the effluent. However, these are practically consumed during the process and the concentrations in the discharge are very low, which are practically diluted during the discharge, without affecting marine ecosystems.[18][19]

Heavy metals

The materials used in SWRO

Discharge

The discharge is generally dumped back into the sea, through an underwater outfall or coastal release, due to its lower energy and economic cost compared to other discharge methods.[19][23] Due to its increase in salinity, the discharge has a greater density compared to the surrounding seawater. Therefore, when the discharge reaches the sea, it can form a saline plume that can tends to follow the bathymetric line of the bottom until it is completely diluted.[24][25][26] The distribution of the salt plume may depend on different factors, such as the production capacity of the plant, the discharge method, the oceanographic and environmental conditions of the discharge point, among others.[15][24][23][27]

Marine environment

Brine discharge might lead to an increase in salinity above certain threshold levels that has the potential to affect benthic communities, especially those more sensitive to osmotic pressure, finally having an effect on their abundance and diversity.[28][29][30]

However, if appropriate mitigation measures are applied, the potential environmental impacts of discharges from SWRO plants can be correctly minimized.[19][27] Some examples can be found in countries such as Spain, Israel, Chile or Australia, in which the mitigation measures adopted reduce the area affected by the discharge, guaranteeing a sustainable development of the desalination process without significant impacts on marine ecosystems.[31][32][33][34][35][27][36] When noticeable effects have been detected on the environment surrounding discharge areas, it generally corresponds to old desalination plants in which the correct mitigation measures were not implemented.[37][31][38] Some examples can be found in Spain, Australia or Chile, where it has been shown that saline plumes do not exceed values of 5% with respect to the natural salinity of the sea in a radius less than 100 m from the point of discharge when proper measures are adopted.[33][27]

Mitigation measures

The mitigation measures that are typically employed to prevent negatively impact sensitive marine enviorment are listed below:[39][40][41]

- A well-designed discharge mechanisms, employing the use of efficient diffusers or pre-dilution of discharges with seawater

- An environmental evaluation study, which assesses the correct location of the discharge point, considering geomorphological and oceanographic variables, such as currents, bathymetry, and type of bottom, which favor a rapid mixing process of the discharges;

- The implementation of an adequate environmental surveillance program, which guarantees the correct operation of the desalination plants during their operational phase, allowing an accurate and early diagnostics of potential environmental threats

Regulation

Currently, in many countries, such as

Under the context of this environmental assessment process, numerous countries require compliance with an Environmental Monitoring Program (PVA), in order to evaluate the effectiveness of the preventive and corrective measures established during the environmental assessment process, and thus guarantee the operation of desalination plants without producing significant environmental impacts.[47][48] The PVAs establishes a series of mandatory requirements that are mainly related to the monitoring of discharge, using a series of measurements and characterizations based on physical-chemical and biological information.[47][48] In addition, the PVAs could also include different requirements related to monitoring the effects of seawater intake and those that may potentially be related to effects on the terrestrial environment.

Wastewater

Brine is a byproduct of many industrial processes, such as desalination, power plant cooling towers, produced water from oil and natural gas extraction, acid mine or acid rock drainage, reverse osmosis reject, chlor-alkali wastewater treatment, pulp and paper mill effluent, and waste streams from food and beverage processing. Along with diluted salts, it can contain residues of pretreatment and cleaning chemicals, their reaction byproducts and heavy metals due to corrosion.

Wastewater brine can pose a significant environmental hazard, both due to corrosive and sediment-forming effects of salts and toxicity of other chemicals diluted in it.[49]

Unpolluted brine from desalination plants and cooling towers can be returned to the ocean. From the desalination process, reject brine is produced, which proposes potential damages to the marine life and habitats.[50] To limit the environmental impact, it can be diluted with another stream of water, such as the outfall of a wastewater treatment or power plant. Since brine is heavier than seawater and would accumulate on the ocean bottom, it requires methods to ensure proper diffusion, such as installing underwater diffusers in the sewerage.[51] Other methods include drying in evaporation ponds, injecting to deep wells, and storing and reusing the brine for irrigation, de-icing or dust control purposes.[49]

Technologies for treatment of polluted brine include: membrane filtration processes, such as

Composition and purification

Brine consists of concentrated solution of Na+ and Cl− ions. Sodium chloride per se does not exist in water: it is fully ionized. Other cations found in various brines include K+, Mg2+, Ca2+, and Sr2+. The latter three are problematic because they form scale and they react with soaps. Aside from chloride, brines sometimes contain Br− and I− and, most problematically, SO2−

4. Purification steps often include the addition of calcium oxide to precipitate solid magnesium hydroxide together with gypsum (CaSO4), which can be removed by filtration. Further purification is achieved by fractional crystallization. The resulting purified salt is called evaporated salt or vacuum salt.[1]

See also

- Brine mining – Extracting materials from saltwater

- Brinicle – Sea ice formation

- ocean bottom

References

- ^ ISBN 978-3527306732.

- S2CID 199387639.

- ^ "The Scioto Saline-Ohio's Early Salt Industry" (PDF). dnr.state.oh.us. Archived from the original (PDF) on 2012-10-07.

- ^ "Global Overview of Saline Groundwater Occurrence and Genesis". igrac.net. Archived from the original on 2011-07-23. Retrieved 2017-07-17.

- ^ a b "Secondary Refrigerant Systems". Cool-Info.com. Retrieved 17 July 2017.

- ^ "Calcium Chloride versus Glycol". accent-refrigeration.com. Retrieved 17 July 2017.

- ISBN 978-1566121194. Archived from the original(PDF) on 12 July 2017. Retrieved 17 July 2017.

- ^ Kemmer, Frank N., ed. (1979). The NALCO Water Handbook. McGraw-Hill. pp. 12–7, 12–25.

- ^ "Hard and soft water". GCSE Bitesize. BBC.

- ISBN 978-1-4398-5540-9.

- ^ "Prewetting with Salt Brine for More Effective Roadway Deicing". www.usroads.com. Archived from the original on 2015-01-07. Retrieved 2012-01-14.

- ^ 3. Luís H. Pizetta Zordão, Vinícius A. Oliveira, George E. Totten, Lauralice C.F. Canale, "Quenching power of aqueous salt solution", International Journal of Heat and Mass Transfer, Volume 140, 2019, pp. 807–818.

- ISSN 0011-9164.

- ^ PMID 33128985.

- ^ ISBN 978-0-12-809240-8, retrieved 2024-04-09

- ISSN 0011-9164.

- ISSN 0892-6875.

- PMID 37689149.

- ^ hdl:10045/101370.

- ISSN 0011-9164.

- ISBN 978-953-51-2882-3, retrieved 2024-04-09

- ISSN 0011-9164.

- ^ ISSN 0011-9164.

- ^ ISSN 1944-3994.

- ISSN 0011-9164.

- ISSN 0011-9164.

- ^ PMID 33157504.

- PMID 26781455.

- PMID 25543242.

- ISSN 0011-9164.

- ^ PMID 25543242.

- hdl:10045/101370.

- ^ PMID 31849222.

- ISSN 2296-7745.

- ISSN 0011-9164.

- ISSN 0964-5691.

- .

- ISSN 1944-3994.

- PMID 33157504.

- ISSN 0959-6526.

- ISSN 2073-4441.

- ISSN 0011-9164.

- ISBN 978-0-12-809240-8, retrieved 2024-04-10

- ISSN 0959-6526.

- PMID 32927546.

- ISBN 978-0-12-809240-8, retrieved 2024-04-10

- ^ ISSN 2073-4441.

- ^ ISSN 0011-9164.

- ^ a b "7 Ways to Dispose of Brine Waste". Desalitech. Archived from the original on 27 September 2017. Retrieved 18 July 2017.

- ^ 5. A. Giwa, V. Dufour, F. Al Marzooqi, M. Al Kaabi, S.W. Hasan, "Brine management methods: Recent innovations and current status", Desalination, Volume 407, 2017, pp. 1–23

- ^ "Reverse Osmosis Desalination: Brine disposal". Lenntech. Retrieved 18 July 2017.

- ^ "Novel Technology for Concentration of Brine Using Membrane-Based System" (PDF). Water Today. Retrieved 31 August 2019.