Cellulose

| |

| |

| Identifiers | |

|---|---|

| ChEMBL | |

| ChemSpider |

|

ECHA InfoCard

|

100.029.692 |

| EC Number |

|

| E number | E460 (thickeners, ...) |

| KEGG | |

PubChem CID

|

|

| UNII | |

CompTox Dashboard (EPA)

|

|

| Properties | |

| (C 12H 20O 10) n | |

| Molar mass | 162.1406 g/mol per glucose unit |

| Appearance | white powder |

| Density | 1.5 g/cm3 |

| Melting point | 260–270 °C; 500–518 °F; 533–543 K Decomposes[2] |

| none | |

| Thermochemistry | |

Std enthalpy of (ΔfH⦵298)formation |

−963,000 kJ/mol[clarification needed] |

Std enthalpy of (ΔcH⦵298)combustion |

−2828,000 kJ/mol[clarification needed] |

| Hazards | |

| NFPA 704 (fire diamond) | |

| NIOSH (US health exposure limits): | |

PEL (Permissible)

|

TWA 15 mg/m3 (total) TWA 5 mg/m3 (resp)[2] |

REL (Recommended)

|

TWA 10 mg/m3 (total) TWA 5 mg/m3 (resp)[2] |

IDLH (Immediate danger) |

N.D.[2] |

| Related compounds | |

Related compounds

|

Starch |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

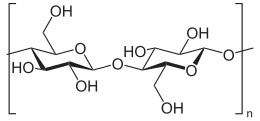

Cellulose is an

Cellulose is mainly used to produce

Some animals, particularly

History

Cellulose was discovered in 1838 by the French chemist Anselme Payen, who isolated it from plant matter and determined its chemical formula.[3][11][12] Cellulose was used to produce the first successful thermoplastic polymer, celluloid, by Hyatt Manufacturing Company in 1870. Production of rayon ("artificial silk") from cellulose began in the 1890s and cellophane was invented in 1912. Hermann Staudinger determined the polymer structure of cellulose in 1920. The compound was first chemically synthesized (without the use of any biologically derived enzymes) in 1992, by Kobayashi and Shoda.[13]

Structure and properties

Cellulose has no taste, is odorless, is

Cellulose is derived from

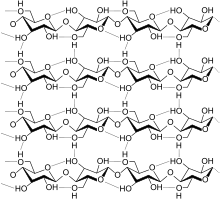

Compared to starch, cellulose is also much more crystalline. Whereas starch undergoes a crystalline to amorphous transition when heated beyond 60–70 °C in water (as in cooking), cellulose requires a temperature of 320 °C and pressure of 25 MPa to become amorphous in water.[19]

Several types of cellulose are known. These forms are distinguished according to the location of hydrogen bonds between and within strands. Natural cellulose is cellulose I, with structures Iα and Iβ. Cellulose produced by bacteria and algae is enriched in Iα while cellulose of higher plants consists mainly of Iβ. Cellulose in

Many properties of cellulose depend on its chain length or degree of polymerization, the number of glucose units that make up one polymer molecule. Cellulose from wood pulp has typical chain lengths between 300 and 1700 units; cotton and other plant fibers as well as bacterial cellulose have chain lengths ranging from 800 to 10,000 units.[6] Molecules with very small chain length resulting from the breakdown of cellulose are known as cellodextrins; in contrast to long-chain cellulose, cellodextrins are typically soluble in water and organic solvents.

The chemical formula of cellulose is (C6H10O5)n where n is the degree of polymerization and represents the number of glucose groups.[21]

Plant-derived cellulose is usually found in a mixture with hemicellulose, lignin, pectin and other substances, while bacterial cellulose is quite pure, has a much higher water content and higher tensile strength due to higher chain lengths.[6]: 3384

Cellulose consists of fibrils with

Processing

Biosynthesis

In

RTCs contain at least three different

Bacterial cellulose is produced using the same family of proteins, although the gene is called BcsA for "bacterial cellulose synthase" or CelA for "cellulose" in many instances.[31] In fact, plants acquired CesA from the endosymbiosis event that produced the chloroplast.[32] All cellulose synthases known belongs to glucosyltransferase family 2 (GT2).[31]

Cellulose synthesis requires chain initiation and elongation, and the two processes are separate. Cellulose synthase (CesA) initiates cellulose polymerization using a

Cellulose is also synthesised by

Breakdown (cellulolysis)

Cellulolysis is the process of breaking down cellulose into smaller polysaccharides called cellodextrins or completely into glucose units; this is a hydrolysis reaction. Because cellulose molecules bind strongly to each other, cellulolysis is relatively difficult compared to the breakdown of other polysaccharides.[35] However, this process can be significantly intensified in a proper solvent, e.g. in an ionic liquid.[36]

Most mammals have limited ability to digest dietary fiber such as cellulose. Some

The enzymes used to

Breakdown (thermolysis)

At temperatures above 350 °C, cellulose undergoes

Semi-crystalline cellulose polymers react at pyrolysis temperatures (350–600 °C) in a few seconds; this transformation has been shown to occur via a solid-to-liquid-to-vapor transition, with the liquid (called intermediate liquid cellulose or molten cellulose) existing for only a fraction of a second.

Continuing decomposition of molten cellulose produces volatile compounds including levoglucosan, furans, pyrans, light oxygenates, and gases via primary reactions.[45] Within thick cellulose samples, volatile compounds such as levoglucosan undergo 'secondary reactions' to volatile products including pyrans and light oxygenates such as glycolaldehyde.[46]

Hemicellulose

Hemicelluloses are polysaccharides related to cellulose that comprises about 20% of the biomass of land plants. In contrast to cellulose, hemicelluloses are derived from several sugars in addition to glucose, especially xylose but also including mannose, galactose, rhamnose, and arabinose. Hemicelluloses consist of shorter chains – between 500 and 3000 sugar units.[47] Furthermore, hemicelluloses are branched, whereas cellulose is unbranched.

Regenerated cellulose

Cellulose is soluble in several kinds of media, several of which are the basis of commercial technologies. These dissolution processes are reversible and are used in the production of regenerated celluloses (such as

The most important solubilizing agent is carbon disulfide in the presence of alkali. Other agents include

The history of regenerated cellulose is often cited as beginning with George Audemars, who first manufactured regenerated

Regenerated cellulose can be used to manufacture a wide variety of products. While the first application of regenerated cellulose was as a clothing textile, this class of materials is also used in the production of disposable medical devices as well as fabrication of artificial membranes.[52]

Cellulose esters and ethers

The

Ester derivatives include:

| Cellulose ester | Reagent | Example | Reagent | Group R |

|---|---|---|---|---|

| Organic esters | Organic acids | Cellulose acetate | Acetic acid and acetic anhydride | H or −(C=O)CH3 |

| Cellulose triacetate | Acetic acid and acetic anhydride | −(C=O)CH3 | ||

| Cellulose propionate | Propionic acid | H or −(C=O)CH2CH3 | ||

| Cellulose acetate propionate (CAP) | Acetic acid and propanoic acid | H or −(C=O)CH3 or −(C=O)CH2CH3 | ||

| Cellulose acetate butyrate (CAB) | Acetic acid and butyric acid | H or −(C=O)CH3 or −(C=O)CH2CH2CH3 | ||

| Inorganic esters | Inorganic acids | Nitrocellulose (cellulose nitrate) | Nitric acid or another powerful nitrating agent | H or −NO2 |

Cellulose sulfate |

Sulfuric acid or another powerful sulfating agent | H or −SO3H |

Cellulose acetate and cellulose triacetate are film- and fiber-forming materials that find a variety of uses. Nitrocellulose was initially used as an explosive and was an early film forming material. When plasticized with camphor, nitrocellulose gives celluloid.

Cellulose Ether[53] derivatives include:

| Cellulose ethers | Reagent | Example | Reagent | Group R = H or | Water solubility | Application | E number |

|---|---|---|---|---|---|---|---|

| Alkyl | Halogenoalkanes

|

Methylcellulose |

Chloromethane | −CH3 | Cold/Hot water-soluble[54] | E461 | |

Ethylcellulose (EC) |

Chloroethane | −CH2CH3 | Water-insoluble | A commercial thermoplastic used in coatings, inks, binders, and controlled-release drug tablets [55] | E462 | ||

| Ethyl methyl cellulose | Chloromethane and chloroethane | −CH3 or −CH2CH3 | E465 | ||||

| Hydroxyalkyl | Epoxides | Hydroxyethyl cellulose | Ethylene oxide | −CH2CH2OH | Cold/hot water-soluble | Gelling and thickening agent [56] | |

| Hydroxypropyl cellulose (HPC) | Propylene oxide | −CH2CH(OH)CH3 | Cold water-soluble | filming properties, coating properties, pharmaceuticals, cultural heritage restoration, electronic applications, cosmetic sector [57] [58] [59] [60] [61] | E463 | ||

| Hydroxyethyl methyl cellulose | Chloromethane and ethylene oxide | −CH3 or −CH2CH2OH | Cold water-soluble | Production of cellulose films | |||

Hydroxypropyl methyl cellulose (HPMC) |

Chloromethane and propylene oxide | −CH3 or −CH2CH(OH)CH3 | Cold water-soluble | Viscosity modifier, gelling, foaming and binding agent | E464 | ||

Ethyl hydroxyethyl cellulose |

Chloroethane and ethylene oxide | −CH2CH3 or −CH2CH2OH | E467 | ||||

| Carboxyalkyl | Halogenated carboxylic acids | Carboxymethyl cellulose (CMC) | Chloroacetic acid | −CH2COOH | Cold/Hot water-soluble | Often used as its sodium salt, sodium carboxymethyl cellulose (NaCMC) | E466 |

The sodium carboxymethyl cellulose can be

Commercial applications

Cellulose for industrial use is mainly obtained from

- Paper products: Cellulose is the major constituent of paper, paperboard, and card stock. Electrical insulation paper: Cellulose is used in diverse forms as insulation in transformers, cables, and other electrical equipment.[67]

- Fibers: Cellulose is the main ingredient of plant fibers (jute, sisal, hemp) represent about 20% of the market. Rayon, cellophane and other "regenerated cellulose fibers" are a small portion (5%).

- Consumables: Microcrystalline cellulose (E460i) and powdered cellulose (E460ii) are used as inactive fillers in drug tablets[68] and a wide range of soluble cellulose derivatives, E numbers E461 to E469, are used as emulsifiers, thickeners and stabilizers in processed foods. Cellulose powder is, for example, used in processed cheese to prevent caking inside the package. Cellulose occurs naturally in some foods and is an additive in manufactured foods, contributing an indigestible component used for texture and bulk, potentially aiding in defecation.[69]

- Building material: Hydroxyl bonding of cellulose in water produces a sprayable, moldable material as an alternative to the use of plastics and resins. The recyclable material can be made water- and fire-resistant. It provides sufficient strength for use as a building material.[70] Cellulose insulation made from recycled paper is becoming popular as an environmentally preferable material for building insulation. It can be treated with boric acid as a fire retardant.

- Miscellaneous: Cellulose can be converted into hydrophilic and highly absorbent sponges. Cellulose is the raw material in the manufacture of nitrocellulose (cellulose nitrate) which is used in smokeless gunpowder.

- Pharmaceuticals: Cellulose derivatives, such as microcrystalline cellulose (MCC), have the advantages of retaining water, being a stabilizer and thickening agent, and in reinforcement of drug tablets.[71]

Aspirational

Energy crops: