Cross-link

In chemistry and biology a cross-link is a bond or a short sequence of bonds that links one

In polymer chemistry "cross-linking" usually refers to the use of cross-links to promote a change in the polymers' physical properties.

When "crosslinking" is used in the biological field, it refers to the use of a probe to link proteins together to check for protein–protein interactions, as well as other creative cross-linking methodologies.[not verified in body]

Although the term is used to refer to the "linking of polymer chains" for both sciences, the extent of crosslinking and specificities of the crosslinking agents vary greatly.

Synthetic polymers

Chemical reactions associated with crosslinking of drying oils, the process that produces linoleum.

Crosslinking generally involves covalent bonds that join two polymer chains. The term

In one implementation, unpolymerized or partially polymerized

Alkyd enamels, the dominant type of commercial oil-based paint, cure by oxidative crosslinking after exposure to air.[4]

Physical cross-links

In contrast to chemical cross-links, physical cross-links are formed by weaker interactions. For example, sodium

Measuring degree of crosslinking

Crosslinking is often measured by swelling tests. The crosslinked sample is placed into a good solvent at a specific temperature, and either the change in mass or the change in volume is measured. The more crosslinking, the less swelling is attainable. Based on the degree of swelling, the Flory Interaction Parameter (which relates the solvent interaction with the sample), and the density of the solvent, the theoretical degree of crosslinking can be calculated according to Flory's Network Theory.[8] Two ASTM standards are commonly used to describe the degree of crosslinking in thermoplastics. In ASTM D2765, the sample is weighed, then placed in a solvent for 24 hours, weighed again while swollen, then dried and weighed a final time.[9] The degree of swelling and the soluble portion can be calculated. In another ASTM standard, F2214, the sample is placed in an instrument that measures the height change in the sample, allowing the user to measure the volume change.[10] The crosslink density can then be calculated.

In biology

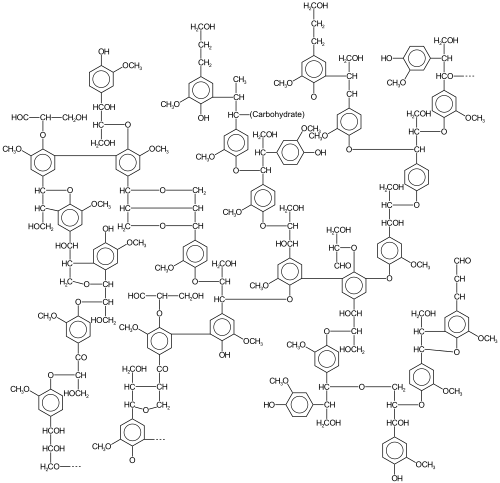

Lignin

Lignin is a highly crosslinked polymer that comprises the main structural material of higher plants. A hydrophobic material, it is derived from precursor monolignols. Heterogeneity arises from the diversity and degree of crosslinking between these lignols.

In DNA

Intrastrand

Proteins

In

The process of applying a

Compromised collagen in the cornea, a condition known as keratoconus, can be treated with clinical crosslinking.[14] In biological context crosslinking could play a role in atherosclerosis through advanced glycation end-products (AGEs), which have been implicated to induce crosslinking of collagen, which may lead to vascular stiffening.[15]

Research

Proteins can also be cross-linked artificially using small-molecule crosslinkers. This approach has been used to elucidate

See also

- Branching (polymer chemistry)

- Cross-linked enzyme aggregate

- Cross-linked polyethylene (PEX)

- Crosslinking of DNA

- Fixation (histology)

- Phenol formaldehyde resin (phenolic resin)

References

- ISBN 978-3-446-40801-2.

- ISBN 9781569902998. Retrieved 1 April 2018 – via Google Books.

- )

- ISBN 978-0-08-087862-1, retrieved 2022-06-27

- PMID 27177209.

- ^ "Experiments: PVA polymer slime". Education: Inspiring your teaching and learning. Royal Society of Chemistry. 2016. Retrieved 2 April 2022.

A solution of polyvinyl alcohol (PVA) can be made into a slime by adding borax solution, which creates cross-links between polymer chains.

- doi:10.1021/ed063p57.

- ^ Flory, P.J., "Principles of Polymer Chemistry" (1953)

- ^ "ASTM D2765 - 16 Standard Test Methods for Determination of Gel Content and Swell Ratio of Crosslinked Ethylene Plastics". www.astm.org. Retrieved 1 April 2018.

- ^ "ASTM F2214 - 16 Standard Test Method for In Situ Determination of Network Parameters of Crosslinked Ultra High Molecular Weight Polyethylene (UHMWPE)". www.astm.org. Retrieved 1 April 2018.

- S2CID 4350565.

- PMID 16464006.

- ISBN 9780471484943.

- ^ Wollensak G, Spoerl E, Seiler T. Riboflavin/ultraviolet-a-induced collagen crosslinking for the treatment of keratoconus. Am J Ophthalmol. 2003 May;135(5):620-7.

- S2CID 8471652.

- ^ "Pierce Protein Biology - Thermo Fisher Scientific". www.piercenet.com. Retrieved 1 April 2018.

- PMID 21873996.

- PMID 33837736.

- ^ PMID 10339534.

- PMID 15782218.