Heat flux

This article needs additional citations for verification. (March 2021) |

| Heat flux | |

|---|---|

Heat flux through a surface. | |

Common symbols | |

SI unit | W/m2 |

Other units | Btu/(h⋅ft2) |

| In SI base units | kg⋅s−3 |

| Dimension | |

In

Heat flux is often denoted , the subscript q specifying heat flux, as opposed to

Fourier's law

For most solids in usual conditions, heat is transported mainly by conduction and the heat flux is adequately described by Fourier's law.

Fourier's law in one dimension

where is the

Multi-dimensional extension

The multi-dimensional case is similar, the heat flux goes "down" and hence the temperature gradient has the negative sign:

Measurement

The measurement of heat flux can be performed in a few different manners.

With a given thermal conductivity

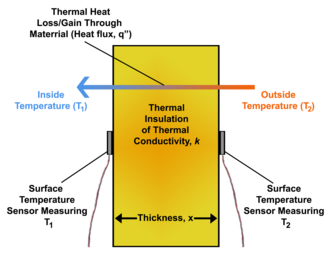

A commonly known, but often impractical, method is performed by measuring a temperature difference over a piece of material with a well-known

With unknown thermal conductivity

A second method of measuring heat flux is by using a heat flux sensor, or heat flux transducer, to directly measure the amount of heat being transferred to/from the surface that the heat flux sensor is mounted to. The most common type of heat flux sensor is a differential temperature thermopile which operates on essentially the same principle as the first measurement method that was mentioned except it has the advantage in that the thermal resistance/conductivity does not need to be a known parameter. These parameters do not have to be known since the heat flux sensor enables an in-situ measurement of the existing heat flux by using the Seebeck effect. However, differential thermopile heat flux sensors have to be calibrated in order to relate their output signals [μV] to heat flux values [W/(m2⋅K)]. Once the heat flux sensor is calibrated it can then be used to directly measure heat flux without requiring the rarely known value of thermal resistance or thermal conductivity.

Science and engineering

One of the tools in a scientist's or engineer's toolbox is the energy balance. Such a balance can be set up for any physical system, from chemical reactors to living organisms, and generally takes the following form

where the three terms stand for the time rate of change of respectively the total amount of incoming energy, the total amount of outgoing energy and the total amount of accumulated energy.

Now, if the only way the system exchanges energy with its surroundings is through heat transfer, the heat rate can be used to calculate the energy balance, since

where we have integrated the heat flux over the surface of the system.

In real-world applications one cannot know the exact heat flux at every point on the surface, but approximation schemes can be used to calculate the integral, for example Monte Carlo integration.

See also

- Radiant flux

- Latent heat flux

- Rate of heat flow

- Insolation

- Heat flux sensor

- Relativistic heat conduction