Hydrogen production

The production of hydrogen plays a key role in any industrialized society, since hydrogen is required for many chemical processes.[4] In 2020, roughly 87 million tons of hydrogen was produced[5] worldwide for various uses, such as oil refining, in the production of ammonia through the Haber process, and in the production of methanol through reduction of carbon monoxide. The global hydrogen generation market was fairly valued at US$155 billion in 2022, and expected to grow at a compound annual growth rate of 9.3% from 2023 to 2030.[6]

As of 2022[update], more than 95% of global hydrogen production is sourced from fossil gas and coal without carbon abatement.[7]: 1

Overview

Molecular hydrogen was discovered in the

Decomposing water, the latter carrier, requires electrical or heat input, generated from some primary energy source (fossil fuel, nuclear power or a renewable energy). Hydrogen produced by electrolysis of water using renewable energy sources such as wind and solar power, referred to as green hydrogen.[9] When derived from natural gas by zero greenhouse emission methane pyrolysis, it is referred to as turquoise hydrogen.[10]

When fossil fuel derived with

Classification based on production method

Hydrogen is often referred to by various colors to indicate its origin (perhaps because gray symbolizes "dirty hydrogen"[13]).[14][15]

| Color | Production source | Notes | References | |

|---|---|---|---|---|

| green | In most definitions, renewable electricity via electrolysis of water. Less frequently, definitions of green hydrogen include hydrogen produced from other low-emisison sources such as biomass. | [17] | ||

| turquoise | thermal splitting of methane | via methane pyrolysis

|

[18]: 28 [19]: 2 | |

| blue | hydrocarbons with carbon capture and storage | CCS networks required | [18]: 28 | |

| gray | fossil hydrocarbons, mainly steam reforming of natural gas | [18]: 28 [20]: 10 [19]: 2 | ||

| brown or black | fossil hydrocarbons: brown (lignite) or black coal | via coal gasification or in a suitable reactor; requires abatement | [21]: 91 | |

| red, pink or purple | nuclear power | via thermochemical water splitting, electrolysis of water, or contributing steam to natural gas reforming | [19]: 2 [13] | |

| yellow | sometimes understood to mean solar photovoltaics | via photovoltaic | [15] | |

gold or white |

hydrogen that occurs naturally deep within the Earth's crust | obtained by mining; also referred to as white | [22] |

Current production methods

Steam reforming – gray or blue

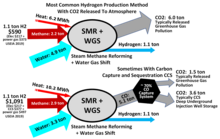

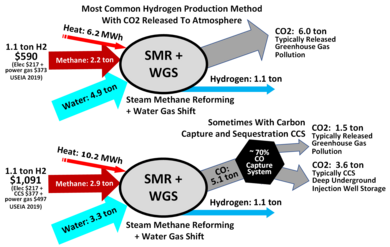

Hydrogen is industrially produced from steam reforming (SMR), which uses natural gas.[23] The energy content of the produced hydrogen is around 74% of the energy content of the original fuel,[24] as some energy is lost as excess heat during production. In general, steam reforming emits carbon dioxide, a greenhouse gas, and is known as gray hydrogen. If the carbon dioxide is captured and stored, the hydrogen produced is known as blue hydrogen.

Steam methane reforming (SMR) produces hydrogen from natural gas, mostly methane (CH4), and water. It is the cheapest source of industrial hydrogen, being the source of nearly 50% of the world's hydrogen.[25] The process consists of heating the gas to 700–1,100 °C (1,300–2,000 °F) in the presence of steam over a nickel catalyst. The resulting endothermic reaction forms carbon monoxide and molecular hydrogen (H2).[26]

In the water-gas shift reaction, the carbon monoxide reacts with steam to obtain further quantities of H2. The WGSR also requires a catalyst, typically over iron oxide or other oxides. The byproduct is CO2.[26] Depending on the quality of the feedstock (natural gas, naphtha, etc.), one ton of hydrogen produced will also produce 9 to 12 tons of CO2, a greenhouse gas that may be captured.[27]

For this process, high temperature steam (H2O) reacts with methane (CH4) in an endothermic reaction to yield syngas.[28]

- CH4 + H2O → CO + 3 H2

In a second stage, additional hydrogen is generated through the lower-temperature, exothermic, water-gas shift reaction, performed at about 360 °C (680 °F):

- CO + H2O → CO2 + H2

Essentially, the oxygen (O) atom is stripped from the additional water (steam) to oxidize CO to CO2. This oxidation also provides energy to maintain the reaction. Additional heat required to drive the process is generally supplied by burning some portion of the methane.

From water

Methods to produce hydrogen without the use of fossil fuels involve the process of water splitting, or splitting the water molecule (H2O) into its components oxygen and hydrogen. When the source of energy for water splitting is renewable or low-carbon, the hydrogen produced is sometimes referred to as green hydrogen. The conversion can be accomplished in several ways, but all methods are currently considered more expensive than fossil-fuel based production methods.

Electrolysis of water – green, pink or yellow

Hydrogen can be made via

In parts of the world, steam methane reforming is between $1–3/kg on average excluding hydrogen gas pressurization cost. This makes production of hydrogen via electrolysis cost competitive in many regions already, as outlined by Nel Hydrogen[33] and others, including an article by the IEA[34] examining the conditions which could lead to a competitive advantage for electrolysis.

A small part (2% in 2019[35]) is produced by electrolysis using electricity and water, consuming approximately 50 to 55 kilowatt-hours of electricity per kilogram of hydrogen produced.[36]

Water electrolysis is using electricity to split water into hydrogen and oxygen. As of 2020, less than 0.1% of hydrogen production comes from water electrolysis.[37] Electrolysis of water is 70–80% efficient (a 20–30% conversion loss)[38][39] while steam reforming of natural gas has a thermal efficiency between 70 and 85%.[40] The electrical efficiency of electrolysis is expected to reach 82–86%[41] before 2030, while also maintaining durability as progress in this area continues apace.[42]

Water electrolysis can operate at 50–80 °C (120–180 °F), while steam methane reforming requires temperatures at 700–1,100 °C (1,300–2,000 °F).[43] The difference between the two methods is the primary energy used; either electricity (for electrolysis) or natural gas (for steam methane reforming). Due to their use of water, a readily available resource, electrolysis and similar water-splitting methods have attracted the interest of the scientific community. With the objective of reducing the cost of hydrogen production, renewable sources of energy have been targeted to allow electrolysis.[44]

There are three main types of

SOECs operate at high temperatures, typically around 800 °C (1,500 °F). At these high temperatures, a significant amount of the energy required can be provided as thermal energy (heat), and as such is termed high-temperature electrolysis. The heat energy can be provided from a number of different sources, including waste industrial heat, nuclear power stations or concentrated solar thermal plants. This has the potential to reduce the overall cost of the hydrogen produced by reducing the amount of electrical energy required for electrolysis.[47][48][49][50]

PEM electrolysis cells typically operate below 100 °C (212 °F).[47] These cells have the advantage of being comparatively simple and can be designed to accept widely varying voltage inputs, which makes them ideal for use with renewable sources of energy such as photovoltaic solar panels.[51] AECs optimally operate at high concentrations of electrolyte (KOH or potassium carbonate) and at high temperatures, often near 200 °C (392 °F).

Industrial output and efficiency

Efficiency of modern hydrogen generators is measured by energy consumed per standard volume of hydrogen (MJ/m3), assuming standard temperature and pressure of the H2. The lower the energy used by a generator, the higher would be its efficiency; a 100%-efficient electrolyser would consume 39.4 kilowatt-hours per kilogram (142 MJ/kg) of hydrogen,[52] 12,749 joules per litre (12.75 MJ/m3). Practical electrolysis typically uses a rotating electrolyser, where centrifugal force helps separate gas bubbles from water.[53] Such an electrolyser at 15 bar pressure may consume 50 kilowatt-hours per kilogram (180 MJ/kg), and a further 15 kilowatt-hours (54 MJ) if the hydrogen is compressed for use in hydrogen cars.[54]

Conventional alkaline electrolysis has an efficiency of about 70%,

PEM efficiency is expected to increase to approximately 86%[58] before 2030. Theoretical efficiency for PEM electrolysers is predicted up to 94%.[59]

As of 2020, the cost of hydrogen by electrolysis is around $3–8/kg.[60] Considering the industrial production of hydrogen, and using current best processes for water electrolysis (PEM or alkaline electrolysis) which have an effective electrical efficiency of 70–82%,[61][62][63] producing 1 kg of hydrogen (which has a specific energy of 143 MJ/kg or about 40 kWh/kg) requires 50–55 kWh of electricity. At an electricity cost of $0.06/kWh, as set out in the Department of Energy hydrogen production targets for 2015,[64] the hydrogen cost is $3/kg.

The US DOE target price for hydrogen in 2020 is $2.30/kg, requiring an electricity cost of $0.037/kWh, which is achievable given recent PPA tenders for wind and solar in many regions.[65] The report by IRENA.ORG is an extensive factual report of present-day industrial hydrogen production consuming about 53 to 70 kWh per kg could go down to about 45 kWh/kg H

2.[66] The thermodynamic energy required for hydrogen by electrolysis translates to 33 kWh/kg, which is higher than steam reforming with carbon capture and higher than methane pyrolysis.

One of the advantages of electrolysis over hydrogen from steam methane reforming (SMR) is that the hydrogen can be produced on-site, meaning that the costly process of delivery via truck or pipeline is avoided.

Chemically assisted electrolysis

In addition to reduce the voltage required for electrolysis via the increasing of the temperature of the electrolysis cell it is also possible to electrochemically consume the oxygen produced in an electrolyser by introducing a fuel (such as carbon/coal,[67] methanol,[68][69] ethanol,[70] formic acid,[71] glycerol,[71] etc.) into the oxygen side of the reactor. This reduces the required electrical energy and has the potential to reduce the cost of hydrogen to less than 40~60% with the remaining energy provided in this manner.[72]

Carbon/hydrocarbon assisted water electrolysis (CAWE) has the potential to offer a less energy intensive, cleaner method of using chemical energy in various sources of carbon, such as low-rank and high sulfur coals, biomass, alcohols and methane (Natural Gas), where pure CO2 produced can be easily sequestered without the need for separation.[73][74]

Hydrogen from biomass – green

Biomass is converted into

Hydrogen as a byproduct of other chemical processes

The industrial production of

Gas generated from coke ovens in steel production is similar to Syngas with 60% hydrogen by volume.[77] The hydrogen can be extracted from the coke oven gas economically.[78]

Other fossil fuel methods

Partial oxidation

Hydrogen production from natural gas and heavier hydrocarbons is achieved by partial oxidation. A fuel-air or fuel-oxygen mixture is partially combusted, resulting in a hydrogen- and carbon monoxide-rich syngas. More hydrogen and carbon dioxide are then obtained from carbon monoxide (and water) via the water-gas shift reaction.[26] Carbon dioxide can be co-fed to lower the hydrogen to carbon monoxide ratio.

The partial oxidation reaction occurs when a substoichiometric fuel-air mixture or fuel-oxygen is partially combusted in a reformer or partial oxidation reactor. A distinction is made between thermal partial oxidation (TPOX) and catalytic partial oxidation (CPOX). The chemical reaction takes the general form:

- 2 CnHm + nO2 → 2n CO + mH2

Idealized examples for heating oil and coal, assuming compositions C12H24 and C24H12 respectively, are as follows:

- C12H24 + 6 O2 → 12 CO + 12 H2

- C24H12 + 12 O2 → 24 CO + 6 H2

Plasma pyrolysis

The Kværner process or Kvaerner carbon black and hydrogen process (CB&H)[79] is a plasma pyrolysis method, developed in the 1980s by a Norwegian company of the same name, for the production of hydrogen and carbon black from liquid hydrocarbons (CnHm). Of the available energy of the feed, approximately 48% is contained in the hydrogen, 40% is contained in activated carbon and 10% in superheated steam.[80] CO2 is not produced in the process.

A variation of this process was presented in 2009 using

Coal

For the production of hydrogen from coal,

Petroleum coke

Petroleum coke can also be converted to hydrogen-rich syngas via coal gasification. The produced syngas consists mainly of hydrogen, carbon monoxide and H2S from the sulfur in the coke feed. Gasification is an option for producing hydrogen from almost any carbon source.[85]

Depleted oil wells

Injecting appropriate microbes into depleted oil wells allows them to extract hydrogen from the remaining, unrecoverable oil. Since the only inputs are the microbes, production costs are low. The method also produces concentrated CO

2 that could in principle be captured.[86]

Radiolysis

Nuclear radiation can break water bonds through

Thermolysis

Water spontaneously dissociates at around 2500 °C, but this

Pyrolysis on biomass

Pyrolysis can be divided into different types based on the pyrolysis temperature, namely low-temperature slow pyrolysis, medium-temperature rapid pyrolysis, and high-temperature flash pyrolysis.[91] The source energy is mainly solar energy, with help of photosynthetic microorganisms to decompose water or biomass to produce hydrogen. However, this process has relatively low hydrogen yields and high operating cost. It is not a feasible method for industry.

Nuclear-assisted thermolysis

The

Bunsen reaction: I2+SO2+2H2O=H2SO4+2HI

HI decomposition: 2HI=H2+I2

Sulfuric acid decomposition: H2SO4=SO2+1/2O2+H2O

The hydrogen production rate of HTGR with IS cycle is approximately 0.68 kg/s, and the capital cost to build a unit of power plant is $100 million.

Thermochemical cycle

The

Ferrosilicon method

Ferrosilicon is used by the military to quickly produce hydrogen for

Photobiological water splitting

Biological hydrogen can be produced in an

Photocatalytic water splitting

The conversion of solar energy to hydrogen by means of water splitting process is one of the most interesting ways to achieve clean and renewable energy systems. However, if this process is assisted by photocatalysts suspended directly in water instead of using photovoltaic and an electrolytic system the reaction is in just one step, it can be made more efficient.[105][106][107] Current systems, however have low performance for commercial implementation.[108][109]

Biohydrogen routes

Biomass and waste streams can in principle be converted into biohydrogen with biomass gasification, steam reforming, or biological conversion like biocatalysed electrolysis[72] or fermentative hydrogen production.[2]

Among hydrogen production methods biological routes are potentially less energy intensive. In addition, a wide variety of waste and low-value materials such as agricultural biomass as renewable sources can be utilized to produce hydrogen via biochemical or thermochemical pathways.[110] Nevertheless, at present hydrogen is produced mainly from fossil fuels, in particular, natural gas which are non-renewable sources. Hydrogen is not only the cleanest fuel but also widely used in a number of industries, especially fertilizer, petrochemical and food ones.[111]

Biochemical routes to hydrogen are classified as dark and photo fermentation processes. In dark fermentation, carbohydrates are converted to hydrogen by fermentative microorganisms including strict anaerobe and facultative anaerobic bacteria. A theoretical maximum of 4 mol H2/mol glucose can be produced.[citation needed] Sugars are convertible to volatile fatty acids (VFAs) and alcohols as by-products during this process. Photo fermentative bacteria are able to generate hydrogen from VFAs. Hence, metabolites formed in dark fermentation can be used as feedstock in photo fermentation to enhance the overall yield of hydrogen.[111]

Fermentative hydrogen production

Fermentative hydrogen production converts organic substrates to hydrogen. A diverse group of bacteria promote this transformation. Photofermentation differs from dark fermentation because it only proceeds in the presence of light. For example, photo-fermentation with Rhodobacter sphaeroides SH2C can be employed to convert some fatty acids into hydrogen.[112]

Fermentative hydrogen production can be done using direct biophotolysis by green algae, indirect biophotolysis by cyanobacteria, photo-fermentation by anaerobic photosynthetic bacteria and dark fermentation by anaerobic fermentative bacteria. For example, studies on hydrogen production using H. salinarium, an anaerobic photosynthetic bacteria, coupled to a hydrogenase donor like E. coli, are reported in literature.[113] Enterobacter aerogenes is another hydrogen producer.[114]

Enzymatic hydrogen generation

Diverse enzymatic pathways have been designed to generate hydrogen from sugars.[115]

Biocatalysed electrolysis

Besides dark fermentation,

Nanogalvanic aluminum alloy powder

Aluminum alloy powder reacts with water to produce hydrogen gas upon contact with water. It reportedly generates hydrogen at 100 percent of the theoretical yield.[118][119] Cost-effective routes for generating the aluminum alloy remain elusive.

CC-HOD

CC-HOD (Catalytic Carbon – Hydrogen On Demand) is a low-temperature process in which carbon and aluminium are submerged and heated to about 80 °C (176 °F), causing a chemical reaction which produces hydrogen.

Natural hydrogen

Hydrogen is also present naturally underground. This natural hydrogen, also called white hydrogen or gold hydrogen, can be extracted from wells in a similar manner as fossil fuels such as oil and natural gas.[120][121]

White hydrogen could be found or produced in the Mid-continental Rift System at scale for a renewable hydrogen economy. Water could be pumped down to hot iron-rich rock to produce hydrogen and the hydrogen could be extracted.[122]

Experimental production methods

Methane pyrolysis – turquoise

Pyrolysis of methane (natural gas) with a one-step process[123] bubbling methane through a molten metal catalyst is a "no greenhouse gas" approach to produce hydrogen that was demonstrated in laboratory conditions in 2017 and now being tested at larger scales.[124][125] The process is conducted at high temperatures (1065 °C).[126][127][128][129] Producing 1 kg of hydrogen requires about 18 kWh of electricity for process heat.[130] The pyrolysis of methane can be expressed by the following reaction equation.[131]

- CH

4(g) → C(s) + 2 H

2(g) ΔH° = 74.8 kJ/mol

The industrial quality solid carbon may be sold as manufacturing feedstock or landfilled (no pollution).

Biological production

Biological hydrogen can be produced in an algae bioreactor. In the late 1990s it was discovered that if the algae is deprived of sulfur it will switch from the production of oxygen, i.e. normal photosynthesis, to the production of hydrogen.[134]

Biological hydrogen can be produced in bioreactors that use feedstocks other than algae, the most common feedstock being waste streams. The process involves bacteria feeding on hydrocarbons and excreting hydrogen and CO2. The CO2 can be sequestered successfully by several methods, leaving hydrogen gas. In 2006–2007, NanoLogix first demonstrated a prototype hydrogen bioreactor using waste as a feedstock at Welch's grape juice factory in North East, Pennsylvania (U.S.).[135]

Biocatalysed electrolysis

Besides regular electrolysis, electrolysis using microbes is another possibility. With biocatalysed electrolysis, hydrogen is generated after running through the microbial fuel cell and a variety of aquatic plants can be used. These include reed sweetgrass, cordgrass, rice, tomatoes, lupines, and algae[136]

High-pressure electrolysis

High-temperature electrolysis

This section needs to be updated. (February 2019) |

Hydrogen can be generated from energy supplied in the form of heat and electricity through high-temperature electrolysis (HTE). Because some of the energy in HTE is supplied in the form of heat, less of the energy must be converted twice (from heat to electricity, and then to chemical form), and so potentially far less energy is required per kilogram of hydrogen produced.

While nuclear-generated electricity could be used for electrolysis, nuclear heat can be directly applied to split hydrogen from water. High temperature (950–1000 °C) gas cooled nuclear reactors have the potential to split hydrogen from water by thermochemical means using nuclear heat. Research into high-temperature nuclear reactors may eventually lead to a hydrogen supply that is cost-competitive with natural gas steam reforming. General Atomics predicts that hydrogen produced in a High Temperature Gas Cooled Reactor (HTGR) would cost $1.53/kg. In 2003, steam reforming of natural gas yielded hydrogen at $1.40/kg. In 2005 natural gas prices, hydrogen costs $2.70/kg.

High-temperature electrolysis has been demonstrated in a laboratory, at 108

Photoelectrochemical water splitting

Using electricity produced by photovoltaic systems offers the cleanest way to produce hydrogen. Water is broken into hydrogen and oxygen by electrolysis – a photoelectrochemical cell (PEC) process which is also named artificial photosynthesis.[143] William Ayers at Energy Conversion Devices demonstrated and patented the first multijunction high efficiency photoelectrochemical system for direct splitting of water in 1983.[144] This group demonstrated direct water splitting now referred to as an "artificial leaf" or "wireless solar water splitting" with a low cost thin film amorphous silicon multijunction sheet immersed directly in water.[145][146]

Hydrogen evolved on the front amorphous silicon surface decorated with various catalysts while oxygen evolved off the back metal substrate. A Nafion membrane above the multijunction cell provided a path for ion transport. Their patent also lists a variety of other semiconductor multijunction materials for the direct water splitting in addition to amorphous silicon and silicon germanium alloys. Research continues towards developing high-efficiency

Photoelectrocatalytic production

A method studied by Thomas Nann and his team at the University of East Anglia consists of a gold electrode covered in layers of indium phosphide (InP) nanoparticles. They introduced an iron-sulfur complex into the layered arrangement, which when submerged in water and irradiated with light under a small electric current, produced hydrogen with an efficiency of 60%.[147]

In 2015, it was reported that

Concentrating solar thermal

Very high temperatures are required to dissociate water into hydrogen and oxygen. A catalyst is required to make the process operate at feasible temperatures. Heating the water can be achieved through the use of water

Thermochemical production

There are more than 352

None of the thermochemical hydrogen production processes have been demonstrated at production levels, although several have been demonstrated in laboratories.

Microwaving plastics

A 97% recovery of hydrogen has been achieved through microwaving plastics for a few seconds that have been ground and mixed with iron oxide and aluminium oxide.[153]

Kværner process

The

Extraction of naturally-occurring hydrogen – White Hydrogen

As of 2019[update], hydrogen is mainly used as an industrial feedstock, primarily for the production of ammonia and methanol, and in petroleum refining. Although initially hydrogen gas was thought not to occur naturally in convenient reservoirs, it is now demonstrated that this is not the case; a hydrogen system is currently being exploited near Bourakebougou, Koulikoro Region in Mali, producing electricity for the surrounding villages.[156] More discoveries of naturally occurring hydrogen in continental, on-shore geological environments have been made in recent years[157] and open the way to the novel field of natural or native hydrogen, supporting energy transition efforts.[158][159]

Environmental impact

As of 2020, most hydrogen is produced from

The use of

Hydrogen produced from

As of 2020[update], estimated costs of production are $1–1.80/kg for grey hydrogen and blue hydrogen,[170] and $2.50–6.80 for green hydrogen.[170]

94 million tonnes of grey hydrogen are produced globally using fossil fuels as of 2022, primarily natural gas, and are therefore a significant source of greenhouse gas emissions.[171][172][173][174]

Hydrogen uses

Hydrogen is used for the conversion of heavy petroleum fractions into lighter ones via

Hydrogen may be used in

Hydrogen is produced as a by-product of industrial chlorine production by electrolysis. Although requiring expensive technologies, hydrogen can be cooled, compressed and purified for use in other processes on site or sold to a customer via pipeline, cylinders or trucks. The discovery and development of less expensive methods of production of bulk hydrogen is relevant to the establishment of a hydrogen economy.[2]

See also

- Ammonia production

- Artificial photosynthesis

- Biohydrogen

- Hydrogen analyzer

- Hydrogen compressor

- broken anchor]

- Hydrogen embrittlement

- Hydrogen leak testing

- Hydrogen pipeline transport

- Hydrogen purifier

- Hydrogen purity

- Hydrogen safety

- Hydrogen sensor

- Hydrogen storage

- Hydrogen station

- Hydrogen tank

- Hydrogen tanker

- Hydrogen technologies

- Hydrogen valve

- Industrial gas

- Liquid hydrogen

- Next Generation Nuclear Plant (partly for hydrogen production)

- Hy4Heat

- Lane hydrogen producer

- Linde–Frank–Caro process

- Underground hydrogen storage

References

- ^ "Hydrogen". IEA. Retrieved 2024-03-23.

- ^ ISBN 978-3-527-30673-2.

- ^ "Natural Hydrogen: A Potential Clean Energy Source Beneath Our Feet". Yale E360. Retrieved 2024-03-23.

- ^ Energy, U. S. D. o. The Impact of Increased Use of Hydrogen on Petroleum Consumption and Carbon Dioxide Emissions. 84 (Energy Information Administration, Washington, DC, 2008)

- ^ Collins, Leigh (2021-05-18). "A net-zero world 'would require 306 million tonnes of green hydrogen per year by 2050': IEA | Recharge". Recharge | Latest renewable energy news. Archived from the original on 2021-05-21.

- ^ "Global Hydrogen Generation Market Size Report, 2030".

- S2CID 252584593. Article in press.

- ^ "Natural Hydrogen Energy LLC". Archived from the original on 2020-10-25. Retrieved 2020-09-29.

- ^ "Definition of Green Hydrogen" (PDF). Clean Energy Partnership. Retrieved 2014-09-06.[permanent dead link]

- .

- ^ Sampson2019-02-11T10:48:00+00:00, Joanna (11 February 2019). "Blue hydrogen for a green future". gasworld. Archived from the original on 2019-05-09. Retrieved 2019-06-03.

{{cite web}}: CS1 maint: numeric names: authors list (link) - ^ "Brown coal the hydrogen economy stepping stone | ECT". Archived from the original on 2019-04-08. Retrieved 2019-06-03.

- ^ ISSN 0013-0613. Retrieved 2023-09-26.

- ^ "Hydrogen Color Explained". Sensonic. Retrieved 2023-11-22.

- ^ a b national grid. "The hydrogen colour spectrum". National Grid Group. London, United Kingdom. Retrieved 2022-09-29.

- ^ "What potential for natural hydrogen?". Energy Observer. Retrieved 2023-07-03.

- ^ Deign, Jason (2020-06-29). "So, What Exactly Is Green Hydrogen?". Greentechmedia. Archived from the original on 2022-03-23. Retrieved 2022-02-11.

- ^ a b c BMWi (June 2020). The national hydrogen strategy (PDF). Berlin, Germany: Federal Ministry for Economic Affairs and Energy (BMWi). Archived (PDF) from the original on 2020-12-13. Retrieved 2020-11-27.

- ^ PMID 32835007.

- ^ Sansom, Robert; Baxter, Jenifer; Brown, Andy; Hawksworth, Stuart; McCluskey, Ian (2020). Transitioning to hydrogen: assessing the engineering risks and uncertainties (PDF). London, United Kingdom: The Institution of Engineering and Technology (IET). Archived (PDF) from the original on 2020-05-08. Retrieved 2020-03-22.

- ^ Bruce, S; Temminghoff, M; Hayward, J; Schmidt, E; Munnings, C; Palfreyman, D; Hartley, P (2018). National hydrogen roadmap: pathways to an economically sustainable hydrogen industry in Australia (PDF). Australia: CSIRO. Archived (PDF) from the original on 2020-12-08. Retrieved 2020-11-28.

- ^ Department of Earth Sciences (12 September 2022). "Gold hydrogen". Department of Earth Sciences, Oxford University. Oxford, United Kingdom. Retrieved 2022-09-29.

- ^ "Actual Worldwide Hydrogen Production from ..." Arno A Evers. December 2008. Archived from the original on 2015-02-02. Retrieved 2008-05-09.

- ISBN 978-0-12-804792-7, retrieved 2023-09-22

- ISSN 0360-3199.

- ^ ISBN 978-0-471-77985-8.

- ^ Collodi, Guido (2010-03-11). "Hydrogen Production via Steam Reforming with CO2 Capture" (PDF). CISAP4 4th International Conference on Safety and Environment in the Process Industry. Retrieved 2015-11-28.

- ^ "HFCIT Hydrogen Production: Natural Gas Reforming". U.S. Department of Energy. 2008-12-15.

- PMID 25309898.

- ^ Werner Zittel; Reinhold Wurster (1996-07-08). "Chapter 3: Production of Hydrogen. Part 4: Production from electricity by means of electrolysis". HyWeb: Knowledge – Hydrogen in the Energy Sector. Ludwig-Bölkow-Systemtechnik GmbH. Archived from the original on 2007-02-07. Retrieved 2010-10-01.

- ^ Bjørnar Kruse; Sondre Grinna; Cato Buch (2002-02-13). "Hydrogen – Status and Possibilities". The Bellona Foundation. Archived from the original (PDF) on 2011-07-02.

Efficiency factors for PEM electrolysers up to 94% are predicted, but this is only theoretical at this time.

- ^ "high-rate and high efficiency 3D water electrolysis". Grid-shift.com. Archived from the original on 2012-03-22. Retrieved 2011-12-13.

- ^ "Wide Spread Adaption of Competitive Hydrogen Solution" (PDF). nelhydrogen.com. Nel ASA. Archived (PDF) from the original on 2018-04-22. Retrieved 22 April 2018.

- ^ Philibert, Cédric. "Commentary: Producing industrial hydrogen from renewable energy". iea.org. International Energy Agency. Archived from the original on 22 April 2018. Retrieved 22 April 2018.

- ^ IEA H2 2019, p. 37

- ^ "How Much Electricity/Water Is Needed to Produce 1 kg of H2 by Electrolysis?". Archived from the original on 17 June 2020. Retrieved 17 June 2020.

- ^ Petrova, Magdalena (2020-12-04). "Green hydrogen is gaining traction, but still has massive hurdles to overcome". CNBC. Retrieved 2021-06-20.

- ^ "ITM – Hydrogen Refuelling Infrastructure – February 2017" (PDF). level-network.com. Retrieved 17 April 2018.

- ^ "Cost reduction and performance increase of PEM electrolysers" (PDF). fch.europa.eu. Fuel Cells and Hydrogen Joint Undertaking. Retrieved 17 April 2018.

- .

- ^ "Cost reduction and performance increase of PEM electrolysers" (PDF). fch.europa.eu. Fuel Cell and Hydrogen Joint Undertaking. Retrieved 17 April 2018.

- ^ "Report and Financial Statements 30 April 2016" (PDF). itm-power.com. Retrieved 17 April 2018.

- ^ "Hydrogen Production: Natural Gas Reforming". energy.gov. US Department of Energy. Retrieved 17 April 2018.

- ^ a b Hordeski, M. F. Alternative fuels: the future of hydrogen. 171–199 (The Fairmont Press, inc., 2007).

- S2CID 135539661.

- S2CID 248467810.

- ^ .

- doi:10.1039/b718822f.

- ^ In the laboratory, water electrolysis can be done with a simple apparatus like a Hofmann voltameter:"Electrolysis of water and the concept of charge". Archived from the original on 2010-06-13.

- ^ "Nuclear power plants can produce hydrogen to fuel the 'hydrogen economy'" (Press release). American Chemical Society. March 25, 2012. Archived from the original on December 10, 2019. Retrieved March 9, 2013.

- .

- ^ Luca Bertuccioli; et al. (7 February 2014). "Development of water electrolysis in the European Union" (PDF). Client Fuel Cells and Hydrogen Joint Undertaking. Archived from the original (PDF) on 31 March 2015. Retrieved 2 May 2018.

- S2CID 53760672. Retrieved June 12, 2011.

- ^ Stensvold, Tore (26 January 2016). «Coca-Cola-oppskrift» kan gjøre hydrogen til nytt norsk industrieventyr. Teknisk Ukeblad, .

- ISBN 9783527674299. Retrieved 22 April 2018.

- ^ thyssenkrupp. "Hydrogen from water electrolysis – solutions for sustainability". thyssenkrupp-uhde-chlorine-engineers.com. Archived from the original on 19 July 2018. Retrieved 28 July 2018.

- ^ "ITM – Hydrogen Refuelling Infrastructure – February 2017" (PDF). level-network.com. Retrieved 17 April 2018.

- ^ "Cost reduction and performance increase of PEM electrolysers" (PDF). fch.europa.eu. Fuel Cells and Hydrogen Joint Undertaking. Retrieved 17 April 2018.

- ^ Bjørnar Kruse; Sondre Grinna; Cato Buch (13 February 2002). "Hydrogen—Status and Possibilities" (PDF). The Bellona Foundation. p. 20. Archived from the original on 16 September 2013.

{{cite web}}: CS1 maint: unfit URL (link) - ^ Fickling, David (2 December 2020). "Hydrogen Is a Trillion Dollar Bet on the Future". Bloomberg.com. Archived from the original on 2 December 2020.

green hydrogen .. current pricing of around $3 to $8 a kilogram .. gray hydrogen, which costs as little as $1

- ^ Werner Zittel; Reinhold Wurster (1996-07-08). "Chapter 3: Production of Hydrogen. Part 4: Production from electricity by means of electrolysis". HyWeb: Knowledge – Hydrogen in the Energy Sector. Ludwig-Bölkow-Systemtechnik GmbH.

- ^ Bjørnar Kruse; Sondre Grinna; Cato Buch (2002-02-13). "Hydrogen—Status and Possibilities". The Bellona Foundation. Archived from the original (PDF) on 2011-07-02.

Efficiency factors for PEM electrolysers up to 94% are predicted, but this is only theoretical at this time.

- ^ "high-rate and high efficiency 3D water electrolysis". Grid-shift.com. Archived from the original on 2012-03-22. Retrieved 2011-12-13.

- ^ "DOE Technical Targets for Hydrogen Production from Electrolysis". energy.gov. US Department of Energy. Retrieved 22 April 2018.

- ^ Deign, Jason. "Xcel Attracts 'Unprecedented' Low Prices for Solar and Wind Paired With Storage". greentechmedia.com. Wood MacKenzie. Retrieved 22 April 2018.

- ^ accessed June 22, 2021

- .

- .

- .

- .

- ^ .

- ^ PMID 25309898.

- S2CID 117669840.

- S2CID 117669840.

- S2CID 265385618. Retrieved 3 December 2023.

- ^ http://www.nedstack.com/images/stories/news/documents/20120202_Press%20release%20Solvay%20PEM%20Power%20Plant%20start%20up.pdf Archived 2014-12-08 at the Wayback Machine Nedstack

- ^ "Different Gases from Steel Production Processes". Archived from the original on 27 March 2016. Retrieved 5 July 2020.

- ^ "Production of Liquefied Hydrogen Sourced by COG" (PDF). Archived (PDF) from the original on 8 February 2021. Retrieved 8 July 2020.

- ^ "Hydrogen technologies". www.interstatetraveler.us.

- ^ [1][permanent dead link][full citation needed]

- ^ "Kværner-process with plasma arc waste disposal technology". Archived from the original on 2014-03-13. Retrieved 2009-10-13.

- ^ "Emissions Advantages of Gasification". National Energy Technology Laboratory. U.S. Department of Energy.

- ^ "Emissions from burning coal". U.S. EIA. U.S. Energy Information Administration.

- .

- .

- ^ Blain, Loz (2022-10-04). "Oil-eating microbes excrete the world's cheapest "clean" hydrogen". New Atlas. Retrieved 2022-10-06.

- ^ An Introduction to Radiation Chemistry Chapter 7

- ^ Nuclear Hydrogen Production Handbook Chapter 8

- S2CID 22420345.

- ^ "Dream or Reality? Electrification of the Chemical Process Industries". www.aiche-cep.com. Retrieved 2021-08-22.

- ISSN 0961-9534.

- ISSN 1364-0321.

- ^ Producing hydrogen: The Thermochemical cycles

- ^ IEA Energy Technology Essentials – Hydrogen Production & Distribution Archived 2011-11-03 at the Wayback Machine, April 2007

- ^ "HTTR High Temperature engineering Test Reactor". Httr.jaea.go.jp. Archived from the original on 2014-02-03. Retrieved 2014-01-23.

- ^ https://smr.inl.gov/Document.ashx?path=DOCS%2FGCR-Int%2FNHDDELDER.pdf Archived 2016-12-21 at the Wayback Machine. Progress in Nuclear Energy Nuclear heat for hydrogen production: Coupling a very high/high temperature reactor to a hydrogen production plant. 2009

- ^ "Status report 101 – Gas Turbine High Temperature Reactor (GTHTR300C)" (PDF).

- ^ "JAEA'S VHTR FOR HYDROGEN AND ELECTRICITY COGENERATION: GTHTR300C" (PDF). Archived from the original (PDF) on 2017-08-10. Retrieved 2013-12-04.

- ^ Chukwu, C., Naterer, G. F., Rosen, M. A., "Process Simulation of Nuclear-Produced Hydrogen with a Cu-Cl Cycle", 29th Conference of the Canadian Nuclear Society, Toronto, Ontario, Canada, June 1–4, 2008. "Process Simulation of Nuclear-Based Thermochemical Hydrogen Production with a Copper-Chlorine Cycle" (PDF). Archived from the original (PDF) on 2012-02-20. Retrieved 2013-12-04.

- ^ Report No 40: The ferrosilicon process for the generation of hydrogen

- ^ Candid science: conversations with famous chemists, István Hargittai, Magdolna Hargittai, p. 261, Imperial College Press (2000)

ISBN 1-86094-228-8

- PMID 19291418.

- ^ "DOE 2008 Report 25 %" (PDF).

- ^ Jenvanitpanjakul, Peesamai (February 3–4, 2010). Renewable Energy Technology And Prospect On Biohydrogen Study In Thailand (PDF). Steering Committee Meeting and Workshop of APEC Research Network for Advanced Biohydrogen Technology. Taichung: Feng Chia University. Archived from the original (PDF) on July 4, 2013.

- PMID 19536754.

- ISBN 978-0-12-374763-1.

- .

- S2CID 21261127.

- ISSN 2166-532X.

- S2CID 265385618. Retrieved 29 December 2023.

- ^ .

- .

- ^ Rajanandam, Brijesh; Kiran, Siva (2011). "Optimization of hydrogen production by Halobacterium salinarium coupled with E coli using milk plasma as fermentative substrate". Journal of Biochemical Technology. 3 (2): 242–4. Archived from the original on 2013-07-31. Retrieved 2013-03-09.

- PMID 28042989.

- PMID 20566280.

- S2CID 96849691.

- "Living plants produce energy". Wageningen University and Research Centre (Press release). Archived from the originalon 2010-05-17.

- "Living plants produce energy".

- ISBN 978-94-6191-282-4.[page needed]

- ^ "Aluminum Based Nanogalvanic Alloys for Hydrogen Generation". U.S. Army Combat Capabilities Development Command Army Research Laboratory. Retrieved January 6, 2020.

- ^ McNally, David (July 25, 2017). "Army discovery may offer new energy source". U.S. Army. Retrieved January 6, 2020.

- .

- ^ Hand, Eric. "Hidden hydrogen". science.org. Science. Retrieved 9 December 2023.

- ^ "The Potential for Geologic Hydrogen for Next-Generation Energy | U.S. Geological Survey".

- ^ Fernandez, Sonia. "Researchers develop potentially low-cost, low-emissions technology that can convert methane without forming CO2". Phys-Org. American Institute of Physics. Archived from the original on 19 October 2020. Retrieved 19 October 2020.

- ^ BASF. "BASF researchers working on fundamentally new, low-carbon production processes, Methane Pyrolysis". United States Sustainability. BASF. Archived from the original on 19 October 2020. Retrieved 19 October 2020.

- .

- S2CID 206663568.

- S2CID 210862772.

- ^ Cartwright, Jon. "The reaction that would give us clean fossil fuels forever". NewScientist. New Scientist Ltd. Archived from the original on 26 October 2020. Retrieved 30 October 2020.

- ^ Karlsruhe Institute of Technology. "Hydrogen from methane without CO2 emissions". Phys.Org. Archived from the original on 21 October 2020. Retrieved 30 October 2020.

- ^ Proceedings hcei.tsc.ru

- S2CID 244814932. Retrieved 16 March 2022.

- .

- ^ "Hydrogen production from organic solid matter". Biohydrogen.nl. Archived from the original on 2011-07-20. Retrieved 2010-07-05.

- PMID 19291418.

- ^ "NanoLogix generates energy on-site with bioreactor-produced hydrogen". Solid State Technology. September 20, 2007. Archived from the original on 2018-05-15. Retrieved 14 May 2018.

- ^ "Power from plants using microbial fuel cell" (in Dutch). Archived from the original on 2021-02-08. Retrieved 2010-07-05.

- ^ Janssen, H; Emonts, B.; Groehn, H. G.; Mai, H.; Reichel, R.; Stolten, D. (1 July 2001). High pressure electrolysis : the key technology for efficient H2 production (PDF). Hypothesis IV: Hydrogen power – theoretical and engineering solutions international symposium. [permanent dead link]

- .

- ^ "2003-PHOEBUS-Pag.9" (PDF). Archived from the original (PDF) on 2009-03-27. Retrieved 2010-07-05.

- ^ "Finland exporting TEN-T fuel stations". December 2015. Archived from the original on 2016-08-28. Retrieved 2016-08-22.

- Science Daily. 2008-09-18. Archivedfrom the original on 2008-09-21. Retrieved 2008-09-19.

- ^ "Nuclear Hydrogen R&D Plan" (PDF). U.S. Dept. of Energy. March 2004. Archived from the original (PDF) on 2008-05-18. Retrieved 2008-05-09.

- PMID 27941752.

- ^ William Ayers, US Patent 4,466,869 Photolytic Production of Hydrogen

- ^ PMID 19536754.

- ^ ISBN 978-0-12-374763-1.

- PMID 20140925.

- Asahi Shimbun. Archived from the originalon August 7, 2015. Retrieved 2015-08-02.

- ^ "DLR Portal – DLR scientists achieve solar hydrogen production in a 100-kilowatt pilot plant". Dlr.de. 2008-11-25. Archived from the original on 2013-06-22. Retrieved 2009-09-19.

- ^ "353 Thermochemical cycles" (PDF). Archived (PDF) from the original on 2009-02-05. Retrieved 2010-07-05.

- ^ UNLV Thermochemical cycle automated scoring database (public)[permanent dead link]

- ^ "Development of Solar-powered Thermochemical Production of Hydrogen from Water" (PDF). Archived (PDF) from the original on 2007-04-17. Retrieved 2010-07-05.

- (PDF) from the original on 2021-07-16. Retrieved 2021-10-24.

- ^ "Bellona-HydrogenReport". Interstatetraveler.us. Archived from the original on 2016-06-03. Retrieved 2010-07-05.

- ^ https://www.hfpeurope.org/infotools/energyinfos__e/hydrogen/main03.html[permanent dead link]

- S2CID 105839304.

- S2CID 128762620.

- .

- .

- ^ "The Potential for Geologic Hydrogen for Next-Generation Energy | U.S. Geological Survey".

- ^ Rapier, Robert (May 26, 2020). "Life Cycle Emissions of Hydrogen Climate". 4thgeneration.energy. Retrieved 2023-12-12.

- ^ Hessler, Uwe (December 6, 2020). "First element in periodic table: Why all the fuss about hydrogen?". dw.com. Deutsche Welle.

- ^ "Air Products to Build Europe’s Largest Blue Hydrogen Plant and Strengthens Long-term Agreement", Air Products press release, November 6, 2023. Retrieved 2023-11-14.

- Wikidata Q108067259.

- ^ Antonini, Cristina, et al. "Hydrogen production from natural gas and biomethane with carbon capture and storage – A techno-environmental analysis", Sustainable Energy & Fuels, Royal Society of Chemistry, 2020. Confirmed 2023-12-12.

- ^ "Facts on low-carbon hydrogen – A European perspective", ZEP Oct 2021. Confirmed 2023-12-12.

- ^ "New Horizons for Hydrogen" (PDF). Research Review (2). National Renewable Energy Laboratory: 2–9. April 2004.

- ^ Dvorak, Phred, "WSJ News Exclusive: Green Hydrogen Gets a Boost in the U.S. With $4 Billion Plant: The planned factory, a joint venture by Air Products and AES ..."], Wall Street Journal, December 8, 2022. Retrieved 2023-11-14. (subscription required)

- ^ Collins, Leigh (25 January 2022). "World first for nuclear-powered pink hydrogen as commercial deal signed in Sweden | Recharge". Recharge | Latest renewable energy news.

- ^ a b Collins, Leigh (19 March 2020). "A wake-up call on green hydrogen: the amount of wind and solar needed is immense | Recharge". Recharge | Latest renewable energy news. Archived from the original on 4 June 2021.

- ^ "How does the energy crisis affect the transition to net zero?". European Investment Bank. Retrieved 2022-12-23.

- ^ "Hydrogen – Fuels & Technologies". IEA. Retrieved 2022-12-23.

- S2CID 253525130.

- ^ "Hydrogen". energy.ec.europa.eu. Retrieved 2022-12-23.

- ^ Ritchie, Hannah. "How many people does synthetic fertilizer feed?". Our World in Data. Global Change Data Lab. Retrieved 16 September 2021.

Sources

Further reading

- Francesco Calise; et al., eds. (2019). Solar Hydrogen Production. Academic Press. ISBN 978-0-12-814853-2.