Intumescent

This article needs additional citations for verification. (December 2022) |

An intumescent is a substance that swells as a result of

The details for individual building parts are specified in technical standards which are compiled and published by national or international standardization bodies like the British Standards Institute (BSI), the German Institute for Standardization (DIN), the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO).

Intumescent coatings for steel constructions must be approved in standardized fire tests.

Types

Soft char

These intumescent materials produce a light char which is a poor conductor of heat, thus retarding heat transfer. Typically the light char consists of microporous carbonaceous foam formed by a chemical reaction of three main components: ammonium polyphosphate, pentaerythritol, and melamine.[2] The reaction takes place in a matrix formed by the molten binder which is typically based on vinyl acetate copolymers or styrene acrylates.

Ablative coatings contain a significant amount of hydrates. When the hydrates are heated, they decompose, and water vapour is released, which has a cooling effect. Once the water is spent, the insulation characteristics of the char that remains can retard heat transfer through the fire stop assembly.

Soft char products are typically used in thin film intumescent materials for fireproofing protection of structural steel as well as in firestop pillows.

Hard char

Harder char is produced with

to fill the gap left in the middle of the fire stop assembly left by the melting plastic pipe.Intumescent coatings

Intumescent coatings may be designed for protection of metals from fire, such as structural steel. Reviews of the technology are available.[3] They may be based on a number of resin binders including epoxy, and silicone.[4] Melamine-formaldehyde resin systems have been used using layered double-hydroxide modified phosphate esters that improved the intumescent properties.[5]

Problems

Some intumescent materials are susceptible to environmental influences such as humidity, which can reduce or negate their ability to function.[citation needed]

Gallery

-

Low pressure intumescent resin: This product is suitable for use in passive fire protection in general, and in firestopping and interior fireproofing in particular. The small, orange chunk on the bottom right is capable of growing into the large black object above and to its left.

-

Pipecovered with a thin-film intumescent spray fireproofing

-

In this picture, the flame has been removed after the thin-film intumescent spray fireproofing product has completely expanded.

-

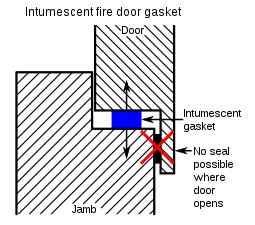

Intumescent gasketing used in passive fire protection, for fire door applications.

See also

- Fire test

- Fire-resistance rating

- Hydrate

- Fire protection

- Passive fire protection

- Firestops

- Putty

- Fireproofing

- Firestop pillow

- Endothermic

- Sodium silicate

- Graphite

- Penetrant (mechanical, electrical, or structural)

- Listing_and_approval_use_and_compliance

- Construction

- Black snake (firework)

- Starlite

References

- ^ Merriam-Webster Dictionary, intumescence, accessed 13 March 2023

- ISBN 978-3527306732.

- S2CID 138961125.

- S2CID 220375908.)

{{cite journal}}: CS1 maint: multiple names: authors list (link - S2CID 199473315.

External links

- "The proof is in the fire" Chemical Innovation Magazine, American Chemical Society

- American Chemical Society: Fire Retardancy of Polypropylene Composites Using Intumescent Coatings

- ASTM E 2786 - 2010 Standard Test Methods for Measuring Expansion of Intumescent Materials Used in Firestop and Joint Systems