Nanoparticle

| Part of a series of articles on |

| Nanomaterials |

|---|

|

| Carbon nanotubes |

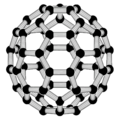

| Fullerenes |

| Other nanoparticles |

| Nanostructured materials |

A nanoparticle or ultrafine particle is a particle of

Nanoparticles are distinguished from microparticles (1-1000 µm), "fine particles" (sized between 100 and 2500 nm), and "coarse particles" (ranging from 2500 to 10,000 nm), because their smaller size drives very different physical or chemical properties, like colloidal properties and ultrafast optical effects[4] or electric properties.[5]

Being more subject to the Brownian motion, they usually do not sediment, like colloidal particles that conversely are usually understood to range from 1 to 1000 nm.

Being much smaller than the wavelengths of

The properties of nanoparticles often differ markedly from those of larger particles of the same substance. Since the typical diameter of an atom is between 0.15 and 0.6 nm, a large fraction of the nanoparticle's material lies within a few atomic diameters of its surface. Therefore, the properties of that surface layer may dominate over those of the bulk material. This effect is particularly strong for nanoparticles dispersed in a medium of different composition since the interactions between the two materials at their interface also becomes significant.[8]

Nanoparticles occur widely in nature and are objects of study in many sciences such as

In general, the small size of nanoparticles leads to a lower concentration of

Non-spherical nanoparticles (e.g., prisms, cubes, rods etc.) exhibit shape-dependent and size-dependent (both chemical and physical) properties (anisotropy).[14][15] Non-spherical nanoparticles of gold (Au), silver (Ag), and platinum (Pt) due to their fascinating optical properties are finding diverse applications. Non-spherical geometries of nanoprisms give rise to high effective cross-sections and deeper colors of the colloidal solutions.[16] The possibility of shifting the resonance wavelengths by tuning the particle geometry allows using them in the fields of molecular labeling, biomolecular assays, trace metal detection, or nanotechnical applications. Anisotropic nanoparticles display a specific absorption behavior and stochastic particle orientation under unpolarized light, showing a distinct resonance mode for each excitable axis. [16]

Definitions

International Union of Pure and Applied Chemistry (IUPAC)

In its 2012 proposed terminology for biologically related polymers, the IUPAC defined a nanoparticle as "a particle of any shape with dimensions in the 1 × 10−9 and 1 × 10−7 m range".[2] This definition evolved from one given by IUPAC in 1997.[17][18]

In another 2012 publication, the IUPAC extends the term to include tubes and fibers with only two dimensions below 100 nm.[3]

International Standards Organization (ISO)

According to the

Common usage

"Nanoscale" is usually understood to be the range from 1 to 100 nm because the novel properties that differentiate particles from the bulk material typically develop at that range of sizes.

For some properties, like transparency or turbidity, ultrafiltration, stable dispersion, etc., substantial changes characteristic of nanoparticles are observed for particles as large as 500 nm. Therefore, the term is sometimes extended to that size range.[citation needed]

Related concepts

Nanoclusters are agglomerates of nanoparticles with at least one dimension between 1 and 10 nanometers and a narrow size distribution.

The terms colloid and nanoparticle are not interchangeable. A colloid is a mixture which has particles of one phase dispersed or suspended within an other phase. The term applies only if the particles are larger than atomic dimensions but small enough to exhibit Brownian motion, with the critical size range (or particle diameter) typically ranging from nanometers (10−9 m) to micrometers (10−6 m).[21] Colloids can contain particles too large to be nanoparticles, and nanoparticles can exist in non-colloidal form, for examples as a powder or in a solid matrix.

History

Natural occurrence

Nanoparticles are naturally produced by many

Pre-industrial technology

Nanoparticles were used by

19th century

Michael Faraday provided the first description, in scientific terms, of the optical properties of nanometer-scale metals in his classic 1857 paper. In a subsequent paper, the author (Turner) points out that: "It is well known that when thin leaves of gold or silver are mounted upon glass and heated to a temperature that is well below a red heat (~500 °C), a remarkable change of properties takes place, whereby the continuity of the metallic film is destroyed. The result is that white light is now freely transmitted, reflection is correspondingly diminished, while the electrical resistivity is enormously increased."[29][30][31]

20th century

During the 1970s and 80s, when the first thorough fundamental studies with nanoparticles were underway in the United States by Granqvist and Buhrman[32] and Japan within an ERATO Project,[33] researchers used the term ultrafine particles. However, during the 1990s, before the National Nanotechnology Initiative was launched in the United States, the term nanoparticle had become more common, for example, see the same senior author's paper 20 years later addressing the same issue, lognormal distribution of sizes.[34]

Morphology and structure

Nanoparticles occur in a great variety of shapes, which have been given many informal names such as nanospheres,[35] nanorods, nanochains,[36] decagedral nanoparticles, nanostars, nanoflowers, nanoreefs,[37] nanowhiskers, nanofibers, and nanoboxes.[38]

The shapes of nanoparticles may be determined by the intrinsic crystal habit of the material, or by the influence of the environment around their creation, such as the inhibition of crystal growth on certain faces by coating additives, the shape of emulsion droplets and micelles in the precursor preparation, or the shape of pores in a surrounding solid matrix.[39] Some applications of nanoparticles may require specific shapes, as well as specific sizes or size ranges.

Amorphous particles typically adopt a spherical shape (due to their microstructural isotropy).

The study of fine particles is called micromeritics.

Variations

Semi-solid and soft nanoparticles have been produced. A prototype nanoparticle of semi-solid nature is the

The breakdown of

Nanoparticles with one half

Nucleation and growth

Impact of nucleation

Nucleation lays the foundation for the nanoparticle synthesis. Initial nuclei play a vital role on the size and shape of the nanoparticles that will ultimately form by acting as templating nuclei for the nanoparticle itself. Long-term stability is also determined by the initial nucleation procedures.[43] Homogeneous nucleation occurs when nuclei form uniformly throughout the parent phase and is less common. Heterogeneous nucleation, however, forms on areas such as container surfaces, impurities, and other defects.[44] Crystals may form simultaneously if nucleation is fast, creating a more monodisperse product. However, slow nucleation rates can cause formation of a polydisperse population of crystals with various sizes. Controlling nucleation allows for the control of size, dispersity, and phase of nanoparticles.

The process of nucleation and growth within nanoparticles can be described by nucleation, Ostwald ripening or the two-step mechanism-autocatalysis model.[45]

Nucleation

The original theory from 1927 of nucleation in nanoparticle formation was Classical Nucleation Theory (CNT).[46] It was believed that the changes in particle size could be described by burst nucleation alone. In 1950, Viktor LaMer used CNT as the nucleation basis for his model of nanoparticle growth. There are three portions to the LaMer model: 1. Rapid increase in the concentration of free monomers in solution, 2. fast nucleation of the monomer characterized by explosive growth of particles, 3. Growth of particles controlled by diffusion of the monomer.[47] This model describes that the growth on the nucleus is spontaneous but limited by diffusion of the precursor to the nuclei surface. The LaMer model has not been able to explain the kinetics of nucleation in any modern system.[48][49][50]

Ostwald ripening

Ostwald ripening is a process in which large particles grow at the expense of the smaller particles as a result of dissolution of small particles and deposition of the dissolved molecules on the surfaces of the larger particles. It occurs because smaller particles have a higher surface energy than larger particles.[51] This process is typically undesirable in nanoparticle synthesis as it negatively impacts the functionality of nanoparticles.[citation needed]

Two-step mechanism – autocatalysis model

In 1997, Finke and Watzky proposed a new kinetic model for the nucleation and growth of nanoparticles. This 2-step model suggested that constant slow nucleation (occurring far from supersaturation) is followed by autocatalytic growth where dispersity of nanoparticles is largely determined. This F-W (Finke-Watzky) 2-step model provides a firmer mechanistic basis for the design of nanoparticles with a focus on size, shape, and dispersity control.[52] [53] The model was later expanded to a 3-step and two 4-step models between 2004-2008. Here, an additional step was included to account for small particle aggregation, where two smaller particles could aggregate to form a larger particle.[54] Next, a fourth step (another autocatalytic step) was added to account for a small particle agglomerating with a larger particle.[55][56][57] Finally in 2014, an alternative fourth step was considered that accounted for a atomistic surface growth on a large particle.[58]

Measuring the rate of nucleation

As of 2014, the classical nucleation theory explained that the nucleation rate will correspond to the driving force One method for measuring the nucleation rate is through the induction time method. This process uses the stochastic nature of nucleation and determines the rate of nucleation by analysis of the time between constant supersaturation and when crystals are first detected.[59] Another method includes the probability distribution model, analogous to the methods used to study supercooled liquids, where the probability of finding at least one nucleus at a given time is derived.[citation needed]

As of 2019, the early stages of nucleation and the rates associated with nucleation were modelled through multiscale computational modeling. This included exploration into an improved kinetic rate equation model and density function studies using the phase-field crystal model.[60]

Properties

The properties of a material in nanoparticle form are unusually different from those of the bulk one even when divided into micrometer-size particles.[61][62][63] Many of them arise from spatial confinement of sub-atomic particles (i.e. electrons, protons, photons) and electric fields around these particles. The large surface to volume ratio is also significant factor at this scale.[15]

Controlling properties

The initial nucleation stages of the synthesis process heavily influence the properties of a nanoparticle. Nucleation, for example, is vital to the size of the nanoparticle. A critical radius must be met in the initial stages of solid formation, or the particles will redissolve into the liquid phase.[64] The final shape of a nanoparticle is also controlled by nucleation. Possible final morphologies created by nucleation can include spherical, cubic, needle-like, worm-like, and more particles.[65] Nucleation can be controlled predominately by time and temperature as well as the supersaturation of the liquid phase and the environment of the synthesis overall.[66]

Large surface-area-to-volume ratio

Bulk materials (>100 nm in size) are expected to have constant physical properties (such as

Interfacial layer

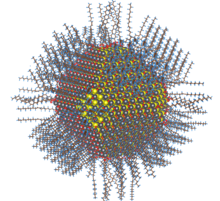

For nanoparticles dispersed in a medium of different composition, the interfacial layer — formed by ions and molecules from the medium that are within a few atomic diameters of the surface of each particle — can mask or change its chemical and physical properties. Indeed, that layer can be considered an integral part of each nanoparticle.[8]

Solvent affinity

Suspensions of nanoparticles are possible since the interaction of the particle surface with the solvent is strong enough to overcome density differences, which otherwise usually result in a material either sinking or floating in a liquid.

Coatings

Nanoparticles often develop or receive coatings of other substances, distinct from both the particle's material and of the surrounding medium. Even when only a single molecule thick, these coatings can radically change the particles' properties, such as and chemical reactivity, catalytic activity, and stability in suspension.

Diffusion across the surface

The high surface area of a material in nanoparticle form allows heat, molecules, and ions to

Ferromagnetic and ferroelectric effects

The small size of nanoparticles affects their magnetic and electric properties. The

Mechanical properties

The reduced

There are unique challenges associated with the measurement of mechanical properties on the nanoscale, as conventional means such as the universal testing machine cannot be employed. As a result, new techniques such as nanoindentation have been developed that complement existing electron microscope and scanning probe methods.[74] Atomic force microscopy (AFM) can be used to perform nanoindentation to measure hardness, elastic modulus, and adhesion between nanoparticle and substrate.[75] The particle deformation can be measured by the deflection of the cantilever tip over the sample. The resulting force-displacement curves can be used to calculate elastic modulus.[76] However, it is unclear whether particle size and indentation depth affect the measured elastic modulus of nanoparticles by AFM.[76]

Adhesion and friction forces are important considerations in nanofabrication, lubrication, device design, colloidal stabilization, and drug delivery.[75] The capillary force is the main contributor to the adhesive force under ambient conditions.[77] The adhesion and friction force can be obtained from the cantilever deflection if the AFM tip is regarded as a nanoparticle. However, this method is limited by tip material and geometric shape.[78] The colloidal probe technique overcomes these issues by attaching a nanoparticle to the AFM tip, allowing control oversize, shape, and material.[79] While the colloidal probe technique is an effective method for measuring adhesion force, it remains difficult to attach a single nanoparticle smaller than 1 micron onto the AFM force sensor.[79]

Another technique is in situ TEM, which provides real-time, high resolution imaging of nanostructure response to a stimulus. For example, an in situ force probe holder in TEM was used to compress twinned nanoparticles and characterize yield strength.[80] In general, the measurement of the mechanical properties of nanoparticles is influenced by many factors including uniform dispersion of nanoparticles, precise application of load, minimum particle deformation, calibration, and calculation model.[75]

Like bulk materials, the properties of nanoparticles are materials dependent. For spherical polymer nanoparticles, glass transition temperature and crystallinity may affect deformation and change the elastic modulus when compared to the bulk material.[75] However, size-dependent behavior of elastic moduli could not be generalized across polymers.[75] As for crystalline metal nanoparticles, dislocations were found to influence the mechanical properties of nanoparticles, contradicting the conventional view that dislocations are absent in crystalline nanoparticles.[75]

Melting point depression

A material may have lower melting point in nanoparticle form than in the bulk form. For example, 2.5 nm gold nanoparticles melt at about 300 °C, whereas bulk gold melts at 1064 °C.[81]

Quantum mechanics effects

Quantum effects are responsible for the deep-red to black color of gold or silicon nanopowders and nanoparticle suspensions.[81] Absorption of solar radiation is much higher in materials composed of nanoparticles than in thin films of continuous sheets of material. In both solar PV and solar thermal applications, by controlling the size, shape, and material of the particles, it is possible to control solar absorption.[83][84][85][86]

Core-shell nanoparticles can support simultaneously both electric and magnetic resonances, demonstrating entirely new properties when compared with bare metallic nanoparticles if the resonances are properly engineered.[87][88][89] The formation of the core-shell structure from two different metals enables an energy exchange between the core and the shell, typically found in upconverting nanoparticles and downconverting nanoparticles, and causes a shift in the emission wavelength spectrum.[90]

By introducing a dielectric layer, plasmonic core (metal)-shell (dielectric) nanoparticles enhance light absorption by increasing scattering. Recently, the metal core-dielectric shell nanoparticle has demonstrated a zero backward scattering with enhanced forward scattering on a silicon substrate when surface plasmon is located in front of a solar cell.[91]

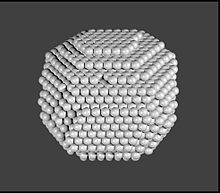

Regular packing

Nanoparticles of sufficiently uniform size may spontaneously settle into regular arrangements, forming a colloidal crystal. These arrangements may exhibit original physical properties, such as observed in photonic crystals.[92][93]

Production

Artificial nanoparticles can be created from any solid or liquid material, including metals, dielectrics, and semiconductors. They may be internally homogeneous or heterogenous, e.g. with a core–shell structure.[87][88][89][94]

There are several methods for creating nanoparticles, including gas condensation, attrition, chemical precipitation,[95] ion implantation, pyrolysis, hydrothermal synthesis, and biosynthesis.[96]

Mechanical

Friable macro- or micro-scale solid particles can be ground in a ball mill, a planetary ball mill, or other size-reducing mechanism until enough of them are in the nanoscale size range. The resulting powder can be air classified to extract the nanoparticles.[97][98][99]

Breakdown of biopolymers

Biopolymers like

.Pyrolysis

Another method to create nanoparticles is to turn a suitable precursor substance, such as a gas (e.g. methane) or aerosol, into solid particles by combustion or pyrolysis. This is a generalization of the burning of hydrocarbons or other organic vapors to generate soot.

Traditional pyrolysis often results in aggregates and agglomerates rather than single primary particles. This inconvenience can be avoided by ultrasonic nozzle spray pyrolysis, in which the precursor liquid is forced through an orifice at high pressure.

Condensation from plasma

Nanoparticles of pure metals,

In RF induction plasma torches, energy coupling to the plasma is accomplished through the electromagnetic field generated by the induction coil. The plasma gas does not come in contact with electrodes, thus eliminating possible sources of contamination and allowing the operation of such plasma torches with a wide range of gases including inert, reducing, oxidizing, and other corrosive atmospheres. The working frequency is typically between 200 kHz and 40 MHz. Laboratory units run at power levels in the order of 30–50 kW, whereas the large-scale industrial units have been tested at power levels up to 1 MW. As the residence time of the injected feed droplets in the plasma is very short, it is important that the droplet sizes are small enough in order to obtain complete evaporation.

Inert gas condensation

Inert-gas condensation is frequently used to produce metallic nanoparticles. The metal is evaporated in a vacuum chamber containing a reduced atmosphere of an inert gas.[101] Condensation of the supersaturated metal vapor results in creation of nanometer-size particles, which can be entrained in the inert gas stream and deposited on a substrate or studied in situ. Early studies were based on thermal evaporation.[101] Using magnetron sputtering to create the metal vapor allows to achieve higher yields.[102] The method can easily be generalized to alloy nanoparticles by choosing appropriate metallic targets. The use of sequential growth schemes, where the particles travel through a second metallic vapor, results in growth of core-shell (CS) structures.[103][104][105][94]

Radiolysis method

Nanoparticles can also be formed using

Wet chemistry

Nanoparticles of certain materials can be created by "wet" chemical processes, in which

The nanoparticles formed by this method are then separated from the solvent and soluble byproducts of the reaction by a combination of

Electroless deposition provides a unique opportunity for growing nanoparticles onto surface without the need for costly spin coating, electrodeposition, or physical vapor deposition. Electroless deposition processes can form colloid suspensions catalytic metal or metal oxide deposition. The suspension of nanoparticles that result from this process is an example of colloid. Typical instances of this method are the production of metal oxide or hydroxide nanoparticles by hydrolysis of metal alkoxides and chlorides.[109][6]

Besides being cheap and convenient, the wet chemical approach allows fine control of the particle's chemical composition. Even small quantities of dopants, such as organic dyes and rare earth metals, can be introduced in the reagent solutions end up uniformly dispersed in the final product.[110][111]

Ion implantation

Ion implantation may be used to treat the surfaces of dielectric materials such as sapphire and silica to make composites with near-surface dispersions of metal or oxide nanoparticles.[citation needed]

Functionalization

Many properties of nanoparticles, notably stability, solubility, and chemical or biological activity, can be radically altered by coating them with various substances — a process called functionalization. Functionalized nanomaterial-based catalysts can be used for catalysis of many known organic reactions.

For example, suspensions of graphene particles can be stabilized by functionalization with gallic acid groups.[112]

For biological applications, the surface coating should be polar to give high aqueous solubility and prevent nanoparticle aggregation. In serum or on the cell surface, highly charged coatings promote non-specific binding, whereas polyethylene glycol linked to terminal hydroxyl or methoxy groups repel non-specific interactions.[113][114] By the immobilization of thiol groups on the surface of nanoparticles or by coating them with thiomers high (muco)adhesive and cellular uptake enhancing properties can be introduced.[115]

Nanoparticles can be

It has been shown that catalytic activity and sintering rates of a functionalized nanoparticle catalyst is correlated to nanoparticles' number density[122]

Coatings that mimic those of red blood cells can help nanoparticles evade the immune system.[123]

Uniformity requirements

The chemical processing and synthesis of high-performance technological components for the private, industrial, and military sectors requires the use of high-purity

Uncontrolled

In addition, any fluctuations in packing density in the compact as it is prepared for the kiln are often amplified during the sintering process, yielding inhomogeneous densification. Some pores and other structural defects associated with density variations have been shown to play a detrimental role in the sintering process by growing and thus limiting end-point densities. Differential stresses arising from inhomogeneous densification have also been shown to result in the propagation of internal cracks, thus becoming the strength-controlling flaws.[127][128][129]

Inert gas evaporation and inert gas deposition

It would, therefore, appear desirable to process a material in such a way that it is physically uniform with regard to the distribution of components and porosity, rather than using particle size distributions that will maximize the green density. The containment of a uniformly dispersed assembly of strongly interacting particles in suspension requires total control over interparticle forces.

Characterization

Nanoparticles have different analytical requirements than conventional chemicals, for which chemical composition and concentration are sufficient metrics. Nanoparticles have other physical properties that must be measured for a complete description, such as size, shape, surface properties, crystallinity, and dispersion state. Additionally, sampling and laboratory procedures can perturb their dispersion state or bias the distribution of other properties.[131][132] In environmental contexts, an additional challenge is that many methods cannot detect low concentrations of nanoparticles that may still have an adverse effect.[131] For some applications, nanoparticles may be characterized in complex matrices such as water, soil, food, polymers, inks, complex mixtures of organic liquids such as in cosmetics, or blood.[133][134]

There are several overall categories of methods used to characterize nanoparticles.

Health and safety

Nanoparticles present possible dangers, both medically and environmentally.

Concern has also been raised over the health effects of respirable nanoparticles from certain combustion processes.

- Carbon nanotubes: Carbon materials have a wide range of uses, ranging from composites for use in vehicles and sports equipment to integrated circuits for electronic components. The interactions between nanomaterials such as carbon nanotubes and natural organic matter strongly influence both their aggregation and deposition, which strongly affects their transport, transformation, and exposure in aquatic environments. In past research, carbon nanotubes exhibited some toxicological impacts that will be evaluated in various environmental settings in current EPA chemical safety research. EPA research will provide data, models, test methods, and best practices to discover the acute health effects of carbon nanotubes and identify methods to predict them.[152]

- Cerium oxide: Nanoscale cerium oxide is used in electronics, biomedical supplies, energy, and fuel additives. Many applications of engineered cerium oxide nanoparticles naturally disperse themselves into the environment, which increases the risk of exposure. There is ongoing exposure to new diesel emissions using fuel additives containing CeO2 nanoparticles, and the environmental and public health impacts of this new technology are unknown. EPA's chemical safety research is assessing the environmental, ecological, and health implications of nanotechnology-enabled diesel fuel additives.[152]

- Titanium dioxide: Nano titanium dioxide is currently used in many products. Depending on the type of particle, it may be found in sunscreens, cosmetics, and paints and coatings. It is also being investigated for use in removing contaminants from drinking water.[152]

- Nano Silver: Nano Silver is being incorporated into textiles, clothing, food packaging, and other materials to eliminate bacteria. EPA and the U.S. Consumer Product Safety Commission are studying certain products to see whether they transfer nano-size silver particles in real-world scenarios. EPA is researching this topic to better understand how much nano-silver children come in contact with in their environments.[152]

- Iron: While iron nutrient supplement, one of its more prominent current uses is to remove contamination from groundwater. This use, supported by EPA research, is being piloted at a number of sites across the United States.[152]

Regulation

As of 2016, the U.S. Environmental Protection Agency had conditionally registered, for a period of four years, only two nanomaterial pesticides as ingredients. The EPA differentiates nanoscale ingredients from non-nanoscale forms of the ingredient, but there is little scientific data about potential variation in toxicity. Testing protocols still need to be developed.[153]

Applications

As the most prevalent morphology of nanomaterials used in consumer products, nanoparticles have an enormous range of potential and actual applications. Table below summarizes the most common nanoparticles used in various product types available on the global markets.

Scientific research on nanoparticles is intense as they have many potential applications in pre-clinical

Polymer reinforcement

Clay nanoparticles, when incorporated into polymer matrices, increase reinforcement, leading to stronger plastics, verifiable by a higher

Liquid properties tuner

The inclusion of nanoparticles in a solid or liquid medium can substantially change its mechanical properties, such as elasticity, plasticity, viscosity, compressibility.[167][168]

Photocatalysis

Being smaller than the wavelengths of visible light, nanoparticles can be dispersed in transparent media without affecting its transparency at those wavelengths. This property is exploited in many applications, such as photocatalysis.[citation needed]

Road paving

Asphalt modification through nanoparticles can be considered as an interesting low-cost technique in asphalt pavement engineering providing novel perspectives in making asphalt materials more durable.[169]

Biomedical

Nanoscale particles are used in biomedical applications as

Sunscreens

Titanium dioxide nanoparticles imparts what is known as the self-cleaning effect, which lend useful water-repellant and antibacterial properties to paints and other products. Zinc oxide nanoparticles have been found to have superior UV blocking properties and are widely used in the preparation of sunscreen lotions,[171] being completely photostable[172] though toxic.[173][174][175][176][177][178]

Compounds by industrial area

See also

- Carbon quantum dot

- Ceramic engineering

- Coating

- Colloid

- Colloidal crystal

- Colloidal gold

- Colloid-facilitated transport

- Eigencolloid

- Fiveling or decahedral nanoparticle

- Fullerene

- Gallium(II) selenide

- Icosahedral twins

- Indium(III) selenide

- Liposome

- Magnetic immunoassay

- Magnetoelastic filament a.k.a. magnetic nanochain

- Magnetic nanoparticles

- Micromeritics

- Nanobiotechnology

- Nanocrystalline silicon

- Nanofluid

- Nanogeoscience

- Nanomaterials

- Nanomedicine

- Nanoparticle deposition

- Nanoparticle tracking analysis

- Nanotechnology

- Patchy particles

- Photonic crystal

- Plasmon

- Platinum nanoparticle

- Quantum dot

- Self-assembly of nanoparticles

- Silicon quantum dot

- Silicon

- Silver Nano

- Sol–gel process

- Synthesis of nanoparticles by fungi

- Transparent material

- Upconverting nanoparticles

References

- ^ U.S. Environmental Protection Agency (): "Module 3: Characteristics of Particles Particle Size Categories". From the EPA Website.

- ^ S2CID 98107080.

- ^ S2CID 98107080.

- S2CID 45625439.

- PMID 37947733.

- ^ .

- .

- ^ PMID 26450215.

- ISBN 978-1-107-12313-7. Retrieved 21 May 2020.

- S2CID 4410909.

- .

- .

- S2CID 40776948.

- ^ "Anisotropic Nanostructures". Mirkin. Retrieved 22 August 2021.

- ^ PMID 22110867.

- ^ PMID 27241479.

- ISBN 978-0-86542-684-9.

- S2CID 97620232.

- ^ "ISO/TS 80004-2: Nanotechnologies Vocabulary Part 2: Nano-objects". International Organization for Standardization. 2015. Retrieved 18 January 2018.

- ISBN 978-1-4020-6119-6.

- ISBN 978-0-19-280672-7. Retrieved 6 December 2016.

- ^ .

- PMID 26030133.

- PMID 22678029.

- ISBN 978-1-4613-4668-5.

- ^ "Nanotechnology Timeline | Nano". www.nano.gov. Retrieved 12 December 2016.

- ISBN 978-1-4200-7545-8.

- ISBN 978-1-4398-2009-4.

- .

- .

- JSTOR 93060.

- ^ .

- ^ a b c d Hayashi, C., Uyeda, R, Tasaki, A. (1997). Ultra-fine particles: exploratory science and technology (1997 Translation of the Japan report of the related ERATO Project 1981 86). Noyes Publications.

- ^ S2CID 250854158.

- PMID 18330181.

- PMID 26394039.

- .

- S2CID 16639413.

- S2CID 136913833.

- .

- PMID 20405913.

- ^ PMID 18076201.

- S2CID 91189669.

- PMID 25003956.

- .

- ^ Volmer M, Weber AZ (1927). "Nucleus Formation in Supersaturated Systems". Zeitschrift für Physikalische Chemie. 125: 236-242.

- .

- .

- S2CID 202880673.

- .

- .

- .

- .

- PMID 15926847.

- .

- .

- PMID 24444431.

- PMID 25003956.

- S2CID 181326215.

- S2CID 35457219.

- ^ ASTM E 2456 06 Standard Terminology Relating to Nanotechnology

- PMID 27960352.

- PMID 21132117.

- .

- PMID 25003956.

- ISBN 978-3-527-40790-3.

- PMID 30202695.

- .

- OCLC 41932585.

- PMID 28809302.

- PMID 19151703.

- .

- ISBN 978-3-540-29857-1

- ^ ISSN 0022-3727.

- ^ PMID 15301482.

- ISSN 0169-4332.

- ISSN 0002-7863.

- ^ ISSN 1521-4117.

- S2CID 137390443.

- ^ .

- ^ PMID 24085009.

- S2CID 98282021.

- ^ .

- ^ PMID 23458793.

- PMID 21711750.

- ^ S2CID 103192810.

- ^ .

- ^ PMID 22204603.

- S2CID 203938224.

- PMID 28794487.

- PMID 1962191.

- S2CID 14113689.

- ^ PMID 38445363.

- PMID 35528557.

- S2CID 89082048.

- PMID 17630692.

- .

- PMID 24316693.

- S2CID 250860605.

- ^ S2CID 53659172.

- doi:10.1063/1.345798.

- .

- ^ PMID 24778973.

- PMID 25180699.

- PMID 30013881.

- doi:10.1039/A801445K.

- ISBN 978-0-12-134970-7.

- .

- ISBN 978-0-7923-9424-2. Retrieved 6 December 2016.

- ISBN 978-0-470-72117-9.

- .

- S2CID 26062996.

- PMID 20025223.

- PMID 34773391.

- PMID 12235356.

- PMID 15611617.

- PMID 17517965.

- S2CID 24702517.

- PMID 15339154.

- PMID 18425138.

- PMID 23607711.

- ^ "Nanoparticles play at being red blood cells". Archived from the original on 1 July 2011. Retrieved 1 July 2011.

- ISBN 978-0-471-65410-0.

- .

- .

- .

- S2CID 137539240.

- .

- .

- ^ S2CID 25291395.

- S2CID 137174566.

- ^ S2CID 23910918.

- hdl:10261/333681.

- S2CID 225410221.

- S2CID 24001137.

- ISBN 978-0-323-52733-0.

- S2CID 663082. Archived from the original(PDF) on 26 September 2020.

- ^ "Toxic Nanoparticles Might be Entering Human Food Supply, MU Study Finds". University of Missouri. 22 August 2013. Retrieved 23 August 2013.

- ISBN 978-0-12-744451-2. Retrieved 6 December 2016.

- S2CID 210119752.[permanent dead link]

- ^ Nanotechnologies: 6. What are potential harmful effects of nanoparticles? europa.eu

- .

- PMID 20709196.

- PMID 20652105.

- PMID 19554862.

- PMID 18360561.

- ^ Howard, V. (2009). "Statement of Evidence: Particulate Emissions and Health (An Bord Plenala, on Proposed Ringaskiddy Waste-to-Energy Facility)." Retrieved 26 April 2011.

- PMID 25756964.

- PMID 36132776.

- S2CID 204266885.

- ^ a b c d e f "Nanomaterials EPA is Assessing". Environmental Protection Agency. Retrieved 6 February 2013.

This article incorporates text from this source, which is in the public domain.

This article incorporates text from this source, which is in the public domain.

- ^ Susan Wayland and Penelope Fenner-Crisp. Reducing Pesticide Risks: A Half Century of Progress. EPA Alumni Association. March 2016.

- ISBN 978-1-003-15350-4, retrieved 23 May 2022

- S2CID 248688540.

- S2CID 6994736.

- PMID 26463476.

- S2CID 709782.

- S2CID 125102995.

- .

- S2CID 125645480.

- PMID 14587824.

- PMID 28818304..

- .

- PMID 29751626.

- ^ "The Textiles Nanotechnology Laboratory". nanotextiles.human.cornell.edu. Retrieved 6 December 2016.

- .

- S2CID 125299766.

- PMID 32641741.

- ^ Mendes, B.B., Conniot, J., Avital, A. et al. Nanodelivery of nucleic acids. Nat Rev Methods Primers 2, 24 (2022). https://doi.org/10.1038/s43586-022-00104-y

- ^ "Sunscreen". U.S. Food and Drug Administration. Retrieved 6 December 2016.

- PMID 9922017.

- S2CID 205976044.

- S2CID 23744621.

- PMID 25966284.

- PMID 26354379.

- PMID 26191382.

- PMID 25924642.

- PMID 15119954.

Further reading

- Jackie Y. Ying (2001). Nanostructured Materials. Academic Press. pp. 5–. ISBN 978-0-12-744451-2.

- Nanoparticles Used in Solar Energy Conversion (ScienceDaily).

- "Nanoparticles: An occupational hygiene review" by RJ Aitken and others. Health and Safety Executive Research Report 274/2004

- "EMERGNANO: A review of completed and near completed environment, health and safety research on nanomaterials and nanotechnology" by RJ Aitken and others.

- High transmission Tandem DMA for nanoparticle studies by SEADM, 2014.

External links

- Nanohedron.com images of nanoparticles

- Lectures on All Phases of Nanoparticle Science and Technology Archived 29 August 2010 at the Wayback Machine

- ENPRA – Risk Assessment of Engineered NanoParticles EC FP7 Project led by the Institute of Occupational Medicine