Natural dye

Natural dyes are

Throughout history, people have dyed their textiles using common, locally available materials, but scarce dyestuffs that produced brilliant and permanent colors such as the natural invertebrate dyes

The discovery of man-made synthetic dyes in the mid-19th century triggered a long decline in the large-scale market for natural dyes. In the early 21st century, the market for natural dyes in the fashion industry is experiencing a resurgence.[4] Western consumers have become more concerned about the health and environmental impact of synthetic dyes—which require the use of toxic fossil fuel byproducts for their production—in manufacturing and there is a growing demand for products that use natural dyes.

Dyes in use in the fashion industry

Because of their different molecular structure, cellulose and protein fibres require different mordant treatments to prepare them for natural dyes.

- Cellulose fibres: cotton, linen, hemp, ramie, bamboo, rayon

- Protein fibres: wool, angora, mohair, cashmere, silk, soy, leather, suede

Cellulose fibres have a lower affinity for natural dyes than do protein fibres. The most common method for preparing cellulose fibres is to use a tannin first (tannins have high affinity for both protein and cellulose fibres), then use an aluminum salt. The most common method for preparing protein fibres is to use alum. However, the historic record contains many hundreds of different mordanting methods for both protein and cellulose fibres.

The types of natural dyes currently popular with craft dyers and the global fashion industry include:[5]

Animal-derived dyes

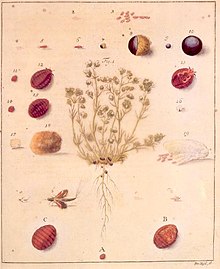

- Cochineal insect (red)

- Cow urine (Indian yellow)

- Lac insect (red, violet)

- Murex snail(purple, indigo blue)

- Octopus/Cuttlefish (sepia brown)

Plant-derived dyes

- Black Walnutor Black Walnut hulls (brown, black, source of tannin)

- Catechu or Cutch tree (brown)

- Gamboge tree resin (dark mustard yellow)

- Chestnut hulls (peach to brown)

- Ebony leaves (black)

- Himalayan rhubarb root (bronze, yellow)

- Indigo leaves (blue to purple)

- Kamala seed pods (yellow)

- Katuray (red)

- Madder root (red, pink, orange)

- Mangosteen peel (green, brown, dark brown, purple, crimson)[6]

- Narra wood (red)

- Myrobalan fruit (yellow, green, black, source of tannin)

- Noniroots (red)

- Pomegranate rind (yellow)

- Sappanwood (red)

- Teak leaf (crimson to maroon)[7]

- Sumac or Staghorn Sumac tree (brown, source of tannin)

- Turmeric roots (yellow)

- Weld herb (yellow)

Origins

Colors in the "ruddy" range of reds, browns, and oranges are the first attested colors in a number of ancient textile sites ranging from the

The chemical analysis that would definitively identify the dyes used in ancient textiles has rarely been conducted, and even when a dye such as indigo blue is detected it is impossible to determine which of several indigo-bearing plants was used.[10] Nevertheless, based on the colors of surviving textile fragments and the evidence of actual dyestuffs found in archaeological sites, reds, blues, and yellows from plant sources were in common use by the late Bronze Age and Iron Age.[11]

In the 18th century Jeremias Friedrich Gülich made substantial contributions to refining the dyeing process,[12] making particular progress on setting standards on dyeing sheep wool and many other textiles.[13] His contributions to refining the dyeing process and his theories on color brought much praise by the well known poet and artist Johann Wolfgang von Goethe.[12]

Processes

After mordanting, the essential process of dyeing requires soaking the material containing the dye (the dyestuff) in water, adding the textile to be dyed to the resulting solution (the dyebath), and bringing the solution to a simmer for an extended period, often measured in days or even weeks, stirring occasionally until the color has evenly transferred to the textiles.[14]

Some dyestuffs, such as

Natural alum (aluminum sulfate) has been the most common metallic salt mordant for millennia (see

Across Asia and Africa and the Americas, patterned fabrics were produced using

Some mordants and some dyestuffs produce strong odours, and the process of dyeing often depends on a good supply of fresh water, storage areas for bulky plant materials, vats which can be kept heated (often for days or weeks) along with the necessary fuel, and airy spaces to dry the dyed textiles. Ancient large-scale dye-works tended to be located on the outskirts of populated areas.[19]

Common dyestuffs

Reds and pinks

A variety of plants produce red (or reddish) dyes, including a number of

Turkey red was a strong, very fast red dye for cotton obtained from madder root via a complicated multistep process involving "sumac and oak galls, calf's blood, sheep's dung, oil, soda, alum, and a solution of tin".[22] Turkey red was developed in India and spread to Turkey. Greek workers familiar with the methods of its production were brought to France in 1747, and Dutch and English spies soon discovered the secret. A sanitized version of Turkey red was being produced in Manchester by 1784, and roller-printed dress cottons with a Turkey red ground were fashionable in England by the 1820s.[23][24]

Munjeet or Indian madder (Rubia cordifolia) is native to the

In tropical Asia, a red dye is obtained from sappanwood (

Puccoon or bloodroot (

A delicate rose color in

Technique

In

Oranges

Dyes that create reds and yellows can also yield oranges. Navajo dyers create orange dyes from one-seeded juniper,

Yellows

Yellow dyes are "about as numerous as red ones",

In

Greens

If plants that yield yellow dyes are common, plants that yield green dyes are rare. Both woad and indigo have been used since ancient times in combination with yellow dyes to produce shades of green.

Soft olive greens are also achieved when textiles dyed yellow are treated with an iron mordant. The dull green cloth common to the Iron Age

Navajo textile artist Nonabah Gorman Bryan developed a two-step process for creating green dye. First the

Blues

Blue colorants around the world were derived from indigo dye-bearing plants, primarily those in the genus Indigofera, which are native to the tropics. The primary commercial indigo species in Asia was true indigo (Indigofera tinctoria). India is believed to be the oldest center of indigo dyeing in the Old World. It was a primary supplier of indigo dye to Europe as early as the Greco-Roman era. The association of India with indigo is reflected in the Greek word for the dye, which was indikon (ινδικόν). The Romans used the term indicum, which passed into Italian dialect and eventually into English as the word indigo.

In the Philippines, blue to indigo colors were also obtained from Indigofera tinctoria and related species, known under common names including tarum, dagum, tayum.[26]

In Central and South America, the important blue dyes were Añil (Indigofera suffruticosa) and Natal indigo (Indigofera arrecta).[44]

In temperate climates including Europe, indigo was obtained primarily from woad (

Examples of dyeing with indigo

-

A traditional dyer from Jaipur, India

-

A traditional brass container used to dye cloth in quantity

-

Hands stained with indigo

Purples

In

Choctaw artists traditionally used maple (

Browns

Grays and blacks

In the Philippines, black dye was obtained from ebony (knalum or batulinao) leaves, as well as from indigo.[26]

Lichen

Dye-bearing

Fungi

The American artist

Luxury dyestuffs

From the second millennium BC to the 19th century, a succession of rare and expensive natural dyestuffs came in and out of fashion in the ancient world and then in Europe. In many cases the cost of these dyes far exceeded the cost of the wools and silks they colored, and often only the finest grades of fabrics were considered worthy of the best dyes.

Royal purple

The premier luxury dye of the ancient world was

Murex dyes were fabulously expensive – one snail yields but a single drop of dye – and the

Crimson and scarlet

Tyrian purple retained its place as the premium dye of Europe until it was replaced "in status and desirability"

When kermes-dyed textiles achieved prominence around the mid-11th century, the dyestuff was called "grain" in all Western European languages because the desiccated eggs resemble fine grains of wheat or sand.[53] Textiles dyed with kermes were described as dyed in the grain.[57] Woollens were frequently dyed in the fleece with woad and then piece-dyed in kermes, producing a wide range colors from blacks and grays through browns, murreys, purples, and sanguines.[57] By the 14th and early 15th century, brilliant full grain kermes scarlet was "by far the most esteemed, most regal" color for luxury woollen textiles in the Low Countries, England, France, Spain and Italy.[53]

The rise of formal black

During the course of the 15th century, the civic records show brilliant reds falling out of fashion for civic and high-status garments in the Duchy of Burgundy in favor of dark blues, greens, and most important of all, black.[63][64] The origins of the trend for somber colors are elusive, but are generally attributed to the growing influence of Spain and possibly the importation of Spanish merino wools. The trend spread in the next century: the Low Countries, German states, Scandinavia, England, France, and Italy all absorbed the sobering and formal influence of Spanish dress after the mid-1520s.[64][65]

Producing fast black in the Middle Ages was a complicated process involving multiple dyeings with woad or indigo followed by mordanting, but at the dawn of

Decline and rediscovery

Synthetic dyes, which could be quickly produced in large quantities, quickly superseded natural dyes for the commercial textile production enabled by the

Synthetic dyes

The first synthetic dyes were discovered in the mid-19th century, starting with

Scientists continued to search for new synthetic dyes that would be effective on cellulose fibres like cotton and linen, and that would be more colorfast on wool and silk than the early anilines. Chrome or mordant dyes produced a muted but very fast color range for woollens. These were followed by acid dyes for animal fibres (from 1875) and the synthesis of indigo in Germany in 1880. The work on indigo led to the development of a new class of dyes called vat dyes in 1901 that produced a wide range of fast colors for cellulosic fibers such as cotton.[68] Disperse dyes were introduced in 1923 to color the new textiles of cellulose acetate, which could not be colored with any existing dyes. Today disperse dyes are the only effective means of coloring many synthetics. Reactive dyes for cotton were introduced in the mid-1950s. These petroleum based, synthetic dyes are used both in commercial textile production and in craft dyeing and have widely replaced natural dyes.[68]

Technique preservation

At the same time the

In America, synthetic dyes became popular among a wide range of Native American textile artists; however, natural dyes remained in use, as many textile collectors prefer natural dyes over synthetics. Today, dyeing with natural materials is often practiced as an adjunct to hand spinning, knitting and weaving.[71] It remains a living craft in many traditional cultures of North America, Africa, Asia, and the Scottish Highlands.[72]

Ecological consciousness has prompted a renewed interest in natural-dye techniques. The European Union, for example, has encouraged Indonesian batik cloth producers to switch to natural dyes to improve their export market in Europe.[73]

Contemporary reskilling

While historically, dyers possessed sophisticated knowledge of natural sources of true dye compounds, nowadays the internet contains a lot of inaccurate information about sources—predominantly foods—that are not supported by the historic record or by modern science. In natural dyeing, there are "fast" dye compounds (those that have the necessary molecular structure to form stable chemical bonds with mordants and fibres, and so provide good resistance to fading when washed, exposed to light, or subjected to normal rubbing/abrasion; these are found throughout the historic record), and there are "fugitive" compounds, which are not true dyes (those that fade and wash out quickly, as they lack the molecular structure to form stable bonds, or any bonds at all, to mordants and fibres). Mordanting can not fix fugitive sources to fibres.[74] Fugitive sources include nearly all berries, red cabbage, beets, spinach, black beans, most flowers (though some important true dyes are flower derived) and many others.[75]

Notes

- ISBN 9781119811718.

- ^ Goodwin (1982), p. 11.

- ^ Kerridge (1988), pp. 15, 16, 135.

- ISBN 978-1-59253-541-5.

- ISBN 978-1-59253-541-5.

- .

- . Retrieved February 28, 2019.

- ^ a b Barber (1991), pp. 223–25.

- ^ Rogers, Penelope Walton, "Dyes and Dyeing". In Jenkins (2003), pp. 25–29.

- ^ Barber (1991), pp. 227, 237.

- ^ a b Barber (1991), pp. 228–29.

- ^ a b Goethe, Johann Wolfgang (1840). "Relation to the Technical Operations of the Dyer". Goethe's Theory of Colours. Translated by Eastlake, Charles Lock.

- ^ Goethe, Johann Wolfgang. "Jeremias Friedrich Gülich". Zur Farbenlehre [Goethe's Theory of Colours] (in German).

- ^ Goodwin (1982), pp. 29–31.

- ^ Barber (1991), pp. 235–36, 239.

- ^ Goodwin (1982), pp. 32–34.

- ^ Driessen, Kris. "Cleaning". Quilt History. Retrieved April 22, 2013.

- ^ Gillow & Sentence (1999), pp. 122–36.

- ^ Barber (1991), p. 239.

- ^ a b Barber (1991), p. 232.

- ^ a b Goodwin (1982), pp. 64–65.

- ^ a b Goodwin (1982), p. 65.

- ^ Tozer & Levitt (1983), pp. 29–30.

- ^ Cannon & Cannon (2002), p. 76.

- ^ Cannon & Cannon (2002), p. 80.

- ^ a b c Palasi, Kat (22 February 2022). "Philippine Natural Dyes: A Short Overview". HABI: The Philippine Textile Council. Retrieved 31 May 2023.

- ^ a b c Chancey (2005), p. 37.

- ^ a b c Chancey (2005), p. 51.

- ^ Chancey (2005), p. 66.

- ^ a b c d Bryan & Young (2002), p. 5.

- ^ Bryan & Young (2002), p. 62.

- ^ "Traditional knowledge of rural Japan: "ubai", carbonized plum for color fixing mordant". Satoyama Library. 28 May 2018. Retrieved 28 June 2021.

- YouTube, katakana(紅) Beni Red (safflower; carthamus tinctorius) / June 2018, minutes 5:22–9:45

- ^ Bryan & Young (2002), p. 6.

- ^ a b c d "12 Plant Navajo Dye Chart, Craftperson: Maggie Begay". Bair's Indian Trading Company. Archived from the original on July 7, 2011. Retrieved January 9, 2011.

- ^ a b c Barber (1991), p. 233.

- ^ a b Goodwin (1982), pp. 60–63.

- ^ Roth, Harold A. "Reseda luteola". Alchemy Works. Retrieved January 8, 2011.

- ^ a b Goodwin (1982), p. 63.

- ^ Chancey (2005), p. 47.

- ^ Cannon & Cannon (2002), p. 110.

- ^ Barber (1991), p. 228.

- ^ a b c Chancey (2005), p. 173.

- ^ Goodwin (1982), p. 70.

- ^ Goodwin (1982), pp. 11, 70–76.

- ^ Kerridge (1988), pp. 166–67.

- ^ Goodwin (1982), pp. 107, 112.

- ^ Goodwin (1982), p. 60.

- ^ Bryan & Young (2002), p. 61.

- ^ Goodwin (1982), pp. 87–92.

- ^ Beebee, Dorothy M. (November 30, 2010). "Mushrooms for Color". Retrieved January 9, 2011.

- ^ Beebee, Dorothy M. (Fall 2008). "Miriam C. Rice and Mushrooms for Color". Turkey Red Journal. Retrieved January 9, 2011.

- ^ a b c Munro, John H. "The Anti-Red Shift – To the Dark Side: Colour Changes in Flemish Luxury Woollens, 1300–1500". In Netherton and Owens-Crocker (2007), pp. 56–57.

- ^ a b c Schoeser (2007), p. 118.

- ^ Barber (1991), pp. 230–31.

- ^ Barber (1991), p. 231.

- ^ a b c Munro, John H. "Medieval Woollens: Textiles, Technology, and Organisation". In Jenkins (2003), pp. 214–15.

- ^ Goodwin (1982), p. 56.

- ^ Threads In Tyme, LTD. "Time line of fabrics". Archived from the original on October 28, 2005. Retrieved January 5, 2011.

- ^ Behan, Jeff (Spring 1995). "The bug that changed history". Boatman's Quarterly Review. 8 (2). Grand Canyon River Guides. Archived from the original on 21 June 2006. Retrieved 5 January 2011.

- ^ Schoeser (2007), pp. 121, 248.

- ^ Barber (1982), p. 55.

- ^ Munro (2007), pp. 76–77.

- ^ a b c Munro (2007), pp. 87–93.

- ^ Boucher & Deslandres (1987), pp. 219, 244.

- ^ a b Thompson & Thompson (1987), p. 10.

- ISBN 3527306730.

- ^ a b Thompson & Thompson (1987), pp. 11–12.

- ^ Dictionary of National Biography (1901), "William Morris"

- ^ Parry (1983), pp. 36–46.

- ^ Goodwin (1982), pp. 7–8.

- ^ Gillow & Sentance (1999), pp. 118–19.

- ^ Faizal, Elly Burhaini (October 29, 2011). "Indonesia told to produce more 'green' products". The Jakarta Post. Retrieved November 9, 2011.

- ^ Furry, Margaret S.; Viemont, Bess M. (August 1934). Home dyeing with natural dyes (Report). Washington, D.C.: U.S. Department of Agriculture, Bureau of Home Economics.

- JSTOR 41366682.

References

The section on William Morris incorporates text from the Dictionary of National Biography, supplemental volume 3 (1901), a publication now in the public domain.

- Barber, E. J. W. (1991). Prehistoric Textiles. Princeton University Press. ISBN 0-691-00224-X.

- ISBN 0-8109-1693-2.

- Bryan, Nonabah Gorman & Young, Stella (2002). Navajo Natives Dyes: Their Preparation and Use. Dover Publications. ISBN 978-0-486-42105-6.

- Cannon, John; Cannon, Margaret (2002). Dye Plants and Dyeing (2nd ed.). A&C Black. ISBN 978-0-7136-6374-7.

- Cardon, Dominique (2007). Natural Dyes: Sources, Tradition, Technology and Science. Archetype Publications. ISBN 978-1-904982-00-5.

- Cardon, Dominique (2016). The Dyer's Handbook Memoirs On Dyeing (Translation into English of an anonymous French manuscript held in a private collection consisting of four essays produced around 1763. ed.). Oxford, Philadelphia: Oxbow Books. OCLC 950262477.

- Chancey, Jill R., ed. (2005). By Native Hands: Woven Treasures from the Lauren Rogers Museum of Art. Lauren Rogers Museum of Art. ISBN 0-935903-07-0.

- Flint, India (2008). Eco Colour: Botanical Dyes For Beautiful Textiles. Loveland, CO: Interweave. OCLC 505420554.

- Gillow, John; Sentance, Bryan (1999). World Textiles. Bulfinch. ISBN 0-8212-2621-5.

- Goodwin, Jill (1982). A Dyer's Manual. Pelham. ISBN 0-7207-1327-7.

- Hofenk de Graaf, Judith (2004). The Colourful Past: Origins, Chemistry and Identification of Natural Dyestuffs. Abegg-Stiftung and Archetype Publications. ISBN 1-873132-13-1.

- Jenkins, David, ed. (2003). The Cambridge History of Western Textiles. Cambridge University Press. ISBN 0-521-34107-8.

- Kerridge, Eric (1988). Textile Manufactures in Early Modern England. Manchester University Press. ISBN 978-0-7190-2632-4.

- Netherton, Robin; Owen-Crocker, Gale R., eds. (2007). Medieval Clothing and Textiles. Vol. 3. Boydell Press. ISBN 978-1-84383-291-1.

- Parry, Linda (1983). William Morris Textiles. Viking Press. ISBN 0-670-77074-4.

- Schoeser, Mary (2007). Silk. Yale University Press. ISBN 978-0-300-11741-7.

- Thompson, Frances; Thompson, Tony (1987). Synthetic Dyeing: for Spinners, Weavers, Knitters and Embroiderers. David & Charles. ISBN 0-7153-8874-6.

- Tozer, Jane; Levitt, Sarah (1983). Fabric of Society: a Century of People and their Clothes 1770–1870. Laura Ashley Press. ISBN 0-9508913-0-4.

See also

External links