Printing press

Recreated Gutenberg press at the International Printing Museum, Carson, California | |

| Inventor | Johannes Gutenberg |

|---|---|

| Inception | 1440 |

| Part of a series on the |

| History of printing |

|---|

|

A printing press is a mechanical device for applying pressure to an

In

A finding in 2015 brought evidence of quires as claimed by extensive research, printed in 1444–1446 possibly assigned to Procopius Waldvogel.

From Mainz, the movable-type printing press spread within several decades to over two hundred cities in a dozen European countries.[5] By 1500, printing presses in operation throughout Western Europe had already produced more than twenty million volumes.[5] In the 16th century, with presses spreading further afield, their output rose tenfold to an estimated 150 to 200 million copies.[5] By the mid-17th century, the first printing presses arrived in colonial America in response to the increasing demand for Bibles and other religious literature.[6] The operation of a press became synonymous with the enterprise of printing and lent its name to a new medium of expression and communication, "the press".[7]

The arrival of mechanical movable type printing in Europe in the

History

Economic conditions and intellectual climate

The rapid economic and socio-cultural development of late medieval society in Europe created favorable intellectual and technological conditions for Gutenberg's improved version of the printing press: the entrepreneurial spirit of emerging capitalism increasingly made its impact on medieval modes of production, fostering economic thinking and improving the efficiency of traditional work processes. The sharp rise of medieval learning and literacy amongst the middle class led to an increased demand for books which the time-consuming hand-copying method fell far short of accommodating.[10]

Technological factors

Technologies preceding the press that led to the press's invention included:

The

During the

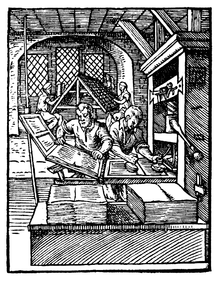

Gutenberg adopted the basic design, thereby mechanizing the printing process.[17] Printing, however, put a demand on the machine quite different from pressing. Gutenberg adapted the construction so that the pressing power exerted by the platen on the paper was now applied both evenly and with the required sudden elasticity. To speed up the printing process, he introduced a movable undertable with a plane surface on which the sheets could be swiftly changed.[18]

The concept of movable type existed prior to 15th century Europe; sporadic evidence that the

Gutenberg greatly improved the process by treating typesetting and printing as two separate work steps. A goldsmith by profession, he created his type pieces from a lead-based alloy which suited printing purposes so well that it is still used today.[22] The mass production of metal letters was achieved by his key invention of a special hand mould, the matrix.[23] The Latin alphabet proved to be an enormous advantage in the process because, in contrast to logographic writing systems, it allowed the type-setter to represent any text with a theoretical minimum of only around two dozen different letters.[24]

Another factor conducive to printing arose from the book existing in the format of the codex, which had originated in the Roman period.[25] Considered the most important advance in the history of the book prior to printing itself, the codex had completely replaced the ancient scroll at the onset of the Middle Ages (AD 500).[26] The codex holds considerable practical advantages over the scroll format: it is more convenient to read (by turning pages), more compact, and less costly, and both recto and verso sides could be used for writing or printing, unlike the scroll.[27]

A fourth development was the early success of medieval papermakers at mechanizing paper manufacture. The introduction of water-powered paper mills, the first certain evidence of which dates to 1282,[28] allowed for a massive expansion of production and replaced the laborious handcraft characteristic of both Chinese[29] and Muslim papermaking.[30] Papermaking centres began to multiply in the late 13th century in Italy, reducing the price of paper to one-sixth of parchment and then falling further; papermaking centers reached Germany a century later.[31]

Despite this it appears that the final breakthrough of paper depended just as much on the rapid spread of movable-type printing.

Function and approach

This section needs additional citations for verification. (April 2020) |

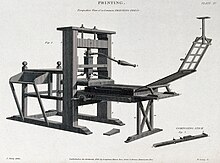

A printing press, in its classical form, is a standing mechanism, ranging from 5 to 7 feet (1.5 to 2.1 m) long, 3 feet (0.91 m) wide, and 7 feet (2.1 m) tall. The small individual metal letters known as type would be set up by a compositor into the desired lines of text. Several lines of text would be arranged at once and were placed in a wooden frame known as a galley. Once the correct number of pages were composed, the galleys would be laid face up in a frame, also known as a forme,[36] which itself is placed onto a flat stone, 'bed,' or 'coffin.' The text is inked using two balls, pads mounted on handles. The balls were made of dog skin leather, because it has no pores,[37] and stuffed with sheep's wool and were inked. This ink was then applied to the text evenly. One damp piece of paper was then taken from a heap of paper and placed on the tympan. The paper was damp as this lets the type 'bite' into the paper better. Small pins hold the paper in place. The paper is now held between a frisket and tympan (two frames covered with paper or parchment).

These are folded down, so that the paper lies on the surface of the inked type. The bed is rolled under the

The function of the printing press was described by William Skeen in 1872:

this sketch represents a press in its completed form, with tympans attached to the end of the carriage, and with the frisket above the tympans. The tympans, inner and outer, are thin iron frames, one fitting into the other, on each of which is stretched a skin of parchment or a breadth of fine cloth. A woollen blanket or two with a few sheets of paper are placed between these, the whole thus forming a thin elastic pad, on which the sheet to be printed is laid. The frisket is a slender frame-work, covered with coarse paper, on which an impression is first taken; the whole of the printed part is then cut out, leaving apertures exactly corresponding with the pages of type on the carriage of the press. The frisket when folded on to the tympans, and both turned down over the forme of types and run in under the platten, preserves the sheet from contact with any thing but the inked surface of the types, when the pull, which brings down the screw and forces the platten to produce the impression, is made by the pressman who works the lever,—to whom is facetiously given the title of "the practitioner at the bar.".[38]

Gutenberg's press

Johannes Gutenberg's work on the printing press began in approximately 1436 when he partnered with Andreas Dritzehn—a man who had previously instructed in gem-cutting—and Andreas Heilmann, owner of a paper mill.[39] However, it was not until a 1439 lawsuit against Gutenberg that an official record existed; witnesses' testimony discussed Gutenberg's types, an inventory of metals (including lead), and his type molds.[39]

Having previously worked as a professional goldsmith, Gutenberg made skillful use of the knowledge of metals he had learned as a craftsman. He was the first to make type from an

Gutenberg is also credited with the introduction of an oil-based ink which was more durable than the previously used water-based inks. As printing material he used both paper and vellum (high-quality parchment). In the Gutenberg Bible, Gutenberg made a trial of colour printing for a few of the page headings, present only in some copies.[41] A later work, the Mainz Psalter of 1453, presumably designed by Gutenberg but published under the imprint of his successors Johann Fust and Peter Schöffer, had elaborate red and blue printed initials.[42]

The Printing Revolution

The

Mass production and spread of printed books

The invention of mechanical movable type printing led to a huge increase of printing activities across Europe within only a few decades. From a single print shop in Mainz, Germany, printing had spread to no less than around 270 cities in Central, Western and Eastern Europe by the end of the 15th century.[48] As early as 1480, there were printers active in 110 different places in Germany, Italy, France, Spain, the Netherlands, Belgium, Switzerland, England, Bohemia and Poland.[5] From that time on, it is assumed that "the printed book was in universal use in Europe".[5]

In Italy, a center of early printing, print shops had been established in 77 cities and towns by 1500. At the end of the following century, 151 locations in Italy had seen at one time printing activities, with a total of nearly three thousand printers known to be active. Despite this proliferation, printing centres soon emerged; thus, one third of the Italian printers published in Venice.[49]

By 1500, the printing presses in operation throughout Western Europe had already produced more than twenty million copies.[5] In the following century, their output rose tenfold to an estimated 150 to 200 million copies.[5]

European printing presses of around 1600 were capable of producing between 1,500

Of

The rapidity of typographical text production, as well as the sharp fall in unit costs, led to the issuing of the first

Incunable are surviving pre-16th century print works which are collected by many of the libraries in Europe and North America.[55]

Circulation of information and ideas

The printing press was also a factor in the establishment of a community of

Because the printing process ensured that the same information fell on the same pages, page numbering, tables of contents, and indices became common, though they previously had not been unknown.[citation needed] The process of reading also changed, gradually moving over several centuries from oral readings to silent, private reading.[citation needed] Over the next 200 years, the wider availability of printed materials led to a dramatic rise in the adult literacy rate throughout Europe.[57]

The printing press was an important step towards the democratization of knowledge.[58][59] Within 50 or 60 years of the invention of the printing press, the entire classical canon had been reprinted and widely promulgated throughout Europe (Eisenstein, 1969; 52). More people had access to knowledge both new and old, more people could discuss these works. Book production became more commercialised, and the first copyright laws were passed.[60] On the other hand, the printing press was criticized for allowing the dissemination of information that may have been incorrect.[61][62]

A second outgrowth of this popularization of knowledge was the decline of Latin as the language of most published works, to be replaced by the vernacular language of each area, increasing the variety of published works. The printed word also helped to unify and standardize the spelling and syntax of these vernaculars, in effect 'decreasing' their variability. This rise in importance of national languages as opposed to pan-European Latin is cited[who?] as one of the causes of the rise of nationalism in Europe.

A third consequence of popularization of printing was on the economy. The printing press was associated with higher levels of city growth.[63] The publication of trade-related manuals and books teaching techniques like double-entry bookkeeping increased the reliability of trade and led to the decline of merchant guilds and the rise of individual traders.[64]

Industrial printing presses

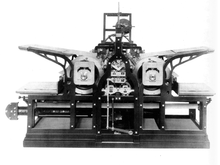

At the dawn of the Industrial Revolution, the mechanics of the hand-operated Gutenberg-style press were still essentially unchanged, although new materials in its construction, amongst other innovations, had gradually improved its printing efficiency. By 1800, Lord Stanhope had built a press completely from cast iron which reduced the force required by 90%, while doubling the size of the printed area.[65] With a capacity of 480 pages per hour, the Stanhope press doubled the output of the old style press.[66] Nonetheless, the limitations inherent to the traditional method of printing became obvious.

Two ideas altered the design of the printing press radically: First, the use of steam power for running the machinery, and second the replacement of the printing flatbed with the rotary motion of cylinders. Both elements were for the first time successfully implemented by the German printer Friedrich Koenig in a series of press designs devised between 1802 and 1818.[67] Having moved to London in 1804, Koenig soon met Thomas Bensley and secured financial support for his project in 1807.[65] Patented in 1810, Koenig had designed a steam press "much like a hand press connected to a steam engine."[65] The first production trial of this model occurred in April 1811. He produced his machine with assistance from German engineer Andreas Friedrich Bauer.

Koenig and Bauer sold two of their first models to

Rotary press

The steam-powered

Also, in the middle of the 19th century, there was a separate development of

Printing capacity

The table lists the maximum number of pages which the various press designs could print per hour.

| Hand-operated presses | Steam-powered presses | |||||

|---|---|---|---|---|---|---|

| Gutenberg-style c. 1600 |

Stanhope press c. 1800 |

Koenig press 1812 |

Koenig press 1813 |

Koenig press 1814 |

Koenig press 1818 | |

| Impressions per hour | 240 [3] | 480 [66] | 800 [71] | 1100 [72] | 2000 [67] | 2400 [67] |

Gallery

-

Printing press from 1811

-

Stanhope press from 1842

-

Imprenta Press V John Sherwin from 1860

-

Reliance Printing Press from the 1890s

-

Toledo Blade newspaper printing press

-

A Miehle flat-bed cylinder press in operation

See also

General:

Printing presses:

- Adana Printing Presses

- Albion press

- Columbian Printing Press

- Flexography

- Vertical print press

Other inventions:

- Color printing

- Composing stick

- Computer printer

- Desktop publishing

- Electronic publishing

- Lithography

- Offset printing

Notes

- Christian era.

- ^ McLuhan 1962; Eisenstein 1980; Febvre & Martin 1997; Man 2002

- ^ a b c d Wolf 1974, pp. 67f.:

From old price tables it can be deduced that the capacity of a printing press around 1600, assuming a fifteen-hour workday, was between 3.200 and 3.600 impressions per day.

- ^ a b Ch'on Hye-bong 1993, p. 12:

This method almost doubled the printing speed and produced more than 40 copies a day. Printing technology reached its peak at this point.

- ^ ISBN 978-968-16-3867-2. pp. 58f.

- ^ Bertold, 1970, pp. 20, 26, 39,

- ^ Weber 2006, p. 387:

At the same time, then, as the printing press in the physical, technological sense was invented, 'the press' in the extended sense of the word also entered the historical stage. The phenomenon of publishing was born.

- ISBN 978-968-16-3867-2, pp. 63–76

- ^ Gerhardt 1978, p. 217

- ^ Eisenstein 1980; Febvre & Martin 1997; Man 2002

- ISBN 978-0-521-43294-8.

- ^ Wolf 1974, pp. 21–35

- ^ Onken 2009; White 1984, pp. 31ff.; Schneider 2007, pp. 156–159

- ^ Schneider 2007, p. 158

- ^ Schulte 1939, p. 56

- ISBN 0-300-08955-4.

- ^ Wolf 1974, pp. 39ff.

- ^ Wolf 1974, pp. 39–46

- ^ Tsien Tsuen-Hsuin; Joseph Needham(1985). Paper and Printing. Science and Civilisation in China. Vol. 5 part 1. Cambridge University Press. pp. 158, 201.

- ^ a b Briggs, Asa and Burke, Peter (2002). A Social History of the Media: From Gutenberg to the Internet, Polity, Cambridge, pp. 15–23, 61–73.

- ^ Germany: Brekle 1995, pp. 23–26, Brekle 1997, p. 62, Brekle 2005, p. 25; England: Lehmann-Haupt 1940, pp. 93–97, Brekle 1997, p. 62; Italy: Lipinsky 1986, pp. 75–80, Koch 1994, p. 213. Lipinsky surmises that this typographical technique was known in Constantinople from the 10th to the 12th century and that the Venetians received it from there (p. 78).

- ^ "Printing". Encyclopædia Britannica (2006).

- ^ Childress 2008, pp. 51–55

- ^ Childress 2008, pp. 51–55; Hellinga 2007, p. 208: "Gutenberg's invention took full advantage of the degree of abstraction in representing language forms that was offered by the alphabet and by the Western forms of script that were current in the fifteenth century."

- ^ Roberts & Skeat 1983, pp. 24–30

- ^ Roberts & Skeat 1983, pp. 1, 38–67, 75: "The most momentous development in the history of the book until the invention of printing was the replacement of the roll by the codex; this we may define as a collection of sheets of any material, folded double and fastened together at the back or spine, and usually protected by covers." (p. 1)

- ^ Roberts & Skeat 1983, pp. 45–53. Technically speaking, a scroll could be written on its back side, too, but the very few ancient specimens found indicate that this was never considered a viable option. (p. 46)

- ^ Burns 1996, p. 418

- ^ Thompson 1978, p. 169; Tsien 1985, p. 68−73; Lucas 2005, p. 28, fn. 70

- ^ Thompson 1978, p. 169; Burns 1996, pp. 414–417

- ^ Burns 1996, p. 417

- ^ Febvre & Martin 1997, pp. 41–44; Burns 1996, p. 419: "In the West, the only inhibiting expense in the production of writings for an increasingly literate market was the manual labor of the scribe himself. With his mechanization by movable-type printing in the 1440s, the manufacture of paper, until then relatively confined, began to spread very widely. The Paper Revolution of the thirteenth century thus entered a new era."

- ^ Roberts & Skeat 1983, pp. 7f.: "Despite all that has been said above, even the strongest supporters of papyrus would not deny that parchment of good quality is the finest writing material ever devised by man. It is immensely strong, remains flexible indefinitely under normal conditions, does not deteriorate with age, and possesses a smooth, even surface which is both pleasant to the eye and provides unlimited scope for the finest writing and illumination."

- ^ The ratio between paper and parchment copies is estimated at around 150 to 30 (Hanebutt-Benz 2000, pp. 158–189).

- ^ Childress 2008, p. 60

- ^ Lyons 2011, p. 59

- ^ [1] RIND Survey (The Press Institute of India- Research Institute for Newspaper Development) June 2015, p14

- ^ Skeen, William (1872). Early Typography. Ceylon: Government Printer, Colombo. p. 122.

- ^ ISBN 0-471-29198-6

- ^ Mahnke 2009, p. 290

- ^ Kapr 1996, p. 172

- ^ Kapr 1996, p. 203

- Eisenstein (1980))

- ^ Newgass, 1958, pp. 32–33

- ^ Bailyn, 1981, pp. 1–3

- ^ Duniway, 1906, pp. 54–56

- ^ Buringh & van Zanden 2009, p. 417, table 2

- ^ "Incunabula Short Title Catalogue". British Library. Archived from the original on 12 March 2011. Retrieved 2 March 2011.

- ^ Borsa 1976, p. 314; Borsa 1977, p. 166−169

- S2CID 144726990.

- ^ Needham 1965, p. 211:

Widmann 1974, p. 34, fn. 14:The outstanding difference between the two ends of the Old World was the absence of screw-presses from China, but this is only another manifestation of the fact that this basic mechanism was foreign to that culture.

Duchesne 2006, p. 83; Man 2002, pp. 112–115:In East Asia, both woodblock and movable type printing were manual reproduction techniques, that is hand printing.

Encyclopædia Britannica 2006: "Printing":Chinese paper was suitable only for calligraphy or block-printing; there were no screw-based presses in the east, because they were not wine-drinkers, didn't have olives, and used other means to dry their paper.

The second necessary element was the concept of the printing press itself, an idea that had never been conceived in the Far East.

- ^ Issawi 1980, pp. 492

- ^ Duchesne 2006, p. 83

- ^ Weber 2006, pp. 387f.

- ISBN 978-3-598-11772-5, pp. 207–224 (207f.), the Incunabula Short Title Cataloguelists 28,107 editions published before 1501.

- ^ Eisenstein 1980.

- ^ Peck, Josh. "The State of Publishing: Literacy Rates." McSweeney's Internet Tendency. McSweeney, 5 July 2011. Web. 28 August 2014.

- ^ SPIEGEL, Malte Herwig, DER (28 March 2007). "Google's Total Library: Putting The World's Books On The Web". Der Spiegel. Archived from the original on 28 January 2012. Retrieved 11 February 2021.

{{cite news}}: CS1 maint: multiple names: authors list (link) - ^ "Howard Rheingold, "Moblogs Seen as a Crystal Ball for a New Era in Online Journalism", Online Journalism Review". 9 August 2003. Archived from the original on 14 October 2012.

- ^ Eshgh, Amy. "Copyright Timeline: A History of Copyright in the United States | Association of Research Libraries® | ARL®". www.arl.org. Retrieved 16 January 2018.

- ISBN 978-0-521-81063-0. Retrieved 25 March 2011.

- ISBN 978-0-307-59111-1. Retrieved 25 March 2011.

- ^ Jeremiah Dittmar. "Information technology and economic change: The impact of the printing press". VoxEU. Retrieved 3 August 2017.

- ^ Prateek Raj. "How the Postal System and the Printing Press Transformed European Markets". Evonomics. Retrieved 3 August 2017.

- ^ ISBN 0-471-29198-6

- ^ a b Bolza 1967, p. 80

- ^ a b c Bolza 1967, p. 88

- ISBN 978-0-471-29198-5.

- ^ "Richard March Hoe | American inventor and manufacturer". Encyclopedia Britannica.

- ^ Peck, Harry Thurston. (1895). The International Cyclopædia A Compendium of Human Knowledge, Revised with Large Additions · Volume 12. Dodd, Mead & Company. p. 168. Retrieved 28 June 2020.

- ^ Bolza 1967, p. 83

- ^ Bolza 1967, p. 87

Bibliography

On the effects of the printing press

- Bailyn, Bernard; Hench, John B., eds. (1981) [1980]. The Press & the American Revolution. Boston: Northeastern University Press (Originally published: Worcester, Mass.: American Antiquarian Society). ISBN 978-0-9303-50307. (Google book)

- Berthold, Arthur Benedict (1970), American colonial printing as determined by contemporary cultural forces, 1639–1763, New York : B. Franklin, ISBN 978-0-8337-02616

- Boruchoff, David A. (2012), "The Three Greatest Inventions of Modern Times: An Idea and Its Public", in Klaus Hock; Gesa Mackenthun (eds.), Entangled Knowledge: Scientific Discourses and Cultural Difference, Münster: Waxmann, pp. 133–163, ISBN 978-3-8309-2729-7

- Buringh, Eltjo; van Zanden, Jan Luiten (2009), "Charting the "Rise of the West": Manuscripts and Printed Books in Europe, A Long-Term Perspective from the Sixth through Eighteenth Centuries", S2CID 154362112

- ISBN 978-0-521-29955-8

- Eisenstein, Elizabeth L. (2005), The Printing Revolution in Early Modern Europe (2nd, rev. ed.), Cambridge University Press, ISBN 978-0-521-60774-2[More recent, abridged version]

- ISBN 978-1-85984-108-2

- ISBN 978-0-7472-4504-9

- ISBN 978-0-8020-6041-9

- —— (1958). Prelude To Independence The Newspaper War On Britain 1764 1776. Alfred A.Knopf.

Technology of printing

- Bechtel, G. (1992), Gutenberg et l'invention de l'imprimerie, Paris: Fayard, ISBN 978-2-213-02865-1

- Bolza, Hans (1967), "Friedrich Koenig und die Erfindung der Druckmaschine", Technikgeschichte, 34 (1): 79–89

- Borsa, Gedeon (1976), "Druckorte in Italien vor 1601", Gutenberg-Jahrbuch: 311–314

- Borsa, Gedeon (1977), "Drucker in Italien vor 1601", Gutenberg-Jahrbuch: 166–169

- Brekle, Herbert E. (1995), "Eine weitere Spur einer typographischen Werkstatt beim Kloster Prüfening im 12. Jahrhundert", Gutenberg-Jahrbuch, 70: 23–26

- Brekle, Herbert E. (1997), "Das typographische Prinzip. Versuch einer Begriffsklärung", Gutenberg-Jahrbuch, 72: 58–63

- Brekle, Herbert E. (2005), Die Prüfeninger Weihinschrift von 1119. Eine paläographisch-typographische Untersuchung (brief summary), Regensburg: Scriptorium Verlag für Kultur und Wissenschaft, ISBN 978-3-937527-06-2

- Burns, Robert I. (1996), "Paper comes to the West, 800–1400", in ISBN 978-3-7861-1748-3

- Childress, Diana (2008), Johannes Gutenberg and the Printing Press, Minneapolis: Twenty-First Century Books, ISBN 978-0-7613-4024-9

- Ch'on Hye-bong: "Typography in Korea", Koreana, Vol. 7, No. 2 (1993), pp. 10–19

- Stearns, Peter N. (ed.). Encyclopedia of World History (6th ed.). The Houghton Mifflin Company/Bartleby.com.

Citation

- Crompton, Samuel Willard (2004), The Printing Press. Transforming Power of Technology, Philadelphia: Chelsea House Publishers, ISBN 978-0-7910-7451-0

- Duchesne, Ricardo (2006), "Asia First?", The Journal of the Historical Society, 6 (1): 69–91,

- Fontaine, Jean-Paul (1999), L'aventure du livre: Du manuscrit medieval a nos jours, Paris: Bibliothèque de l'image

- Gerhardt, Claus W. (1971), "Warum wurde die Gutenberg-Presse erst nach über 350 Jahren durch ein besseres System abgelöst?", Gutenberg-Jahrbuch: 43–57

- Gerhardt, Claus W. (1978), "Besitzt Gutenbergs Erfindung heute noch einen Wert?", Gutenberg-Jahrbuch: 212–217

- Hanebutt-Benz, Eva-Maria (2000), "Gutenbergs Erfindungen", Gutenberg. Aventur und Kunst: Vom Geheimunternehmen zur ersten Medienrevolution, Mainz: Stadt Mainz, pp. 158–189

- Hellinga, Lotte (2007), "The Gutenberg Revolutions", in Eliot, Simon; Rose, Jonathan (eds.), A Companion to the History of the Book, Blackwell Publishing, pp. 207–220, ISBN 978-1-4051-2765-3

- Hind, Arthur M., An Introduction to a History of Woodcut, Houghton Mifflin Co. 1935 (in USA), reprinted Dover Publications, 1963 ISBN 0-486-20952-0

- S2CID 143805644

- Kapr, Albert (1996), Johannes Gutenberg. The Man and his Invention, Aldershot: Scolar, ISBN 978-1-85928-114-7

- Koch, Walter (1994), Literaturbericht zur mittelalterlichen und neuzeitlichen Epigraphik (1985–1991), ISBN 978-3-88612-114-4)

{{citation}}: CS1 maint: location missing publisher (link - Lehmann-Haupt, Hellmut (1940), "Englische Holzstempelalphabete des XIII. Jahrhunderts", Gutenberg-Jahrbuch: 93–97

- Lipinsky, Angelo (1986), "La pala argentea del Patriarca Pellegrino nella Collegiata di Cividale e le sue iscrizioni con caratteri mobili", Ateneo Veneto, 24: 75–80

- Lucas, Adam Robert (2005), "Industrial Milling in the Ancient and Medieval Worlds. A Survey of the Evidence for an Industrial Revolution in Medieval Europe", Technology and Culture, 46 (1): 1–30, S2CID 109564224

- Lyons, Martyn (2011), Books: A Living History, Los Angeles: Getty Publications, ISBN 978-1-60606-083-4

- Mahnke, Helmut (2009), Der kunstreiche Johannes Gutenberg und die Frühzeit der Druckkunst, Norderstedt: Books on Demand, ISBN 978-3-8370-5041-7

- Needham, Joseph: "Science and Civilisation in China", Physics and Physical Technology (Vol. 4), Mechanical Engineering (Part 2), Cambridge University Press, 1965

- Onken, Björn (2009), "Presses", in Cancik, Hubert; Schneider, Helmuth (eds.), Brill's New Pauly

- Encyclopædia Britannica 2006: "Printing". Retrieved 27 November 2006

- Roberts, Colin H.; Skeat, T. C. (1983), The Birth of the Codex, London: Oxford University Press, ISBN 978-0-19-726024-1

- Schneider, Helmuth (2007), "Technology", in ISBN 978-0-521-78053-7

- Schulte, Alfred (1939), "Papierpresse, Druckerpresse und Kelter", Gutenberg-Jahrbuch: 52–56

- Thompson, Susan (1978), "Paper Manufacturing and Early Books", Annals of the New York Academy of Sciences, 314 (1): 167–176, S2CID 85153174

- Tsien, Tsuen-Hsuin (1985), Paper and Printing, Science and Civilisation in China, Chemistry and Chemical Technology (Vol. 5, Part 1), Cambridge University Press

- Weber, Johannes (2006), "Strassburg, 1605: The Origins of the Newspaper in Europe", German History, 24 (3): 387–412,

- White, K. D. (1984), Greek and Roman Technology, London: Thames and Hudson

- Widmann, Hans (1974), "Der koreanische Buchdruck und Gutenbergs Erfindung", Gutenberg-Jahrbuch: 32–34

- Wolf, Hans-Jürgen (1974), Geschichte der Druckpressen (1st ed.), Frankfurt/Main: Interprint

External links

- Centre for the History of the Book (archived 6 June 2016)

- Gutenberg printing − Photos of Incunabula and the Gutenberg Bible (1455) (archived 28 September 2007)

- Internet Archive: Printing (1947) − a film from the Prelinger Archives explaining the printing industry