Reed water tube boiler

The Reed water tube boiler was a type of

Intended for use in the

Design

The Reed water tube boiler was developed and

It was similar to its antecedent the

In the Normand boiler, the tubes were comparatively straight and a portion of those in the inner and outer rows of each bank were formed into "tube walls" to direct hot gases generated by the furnace through the boiler.

Steam was collected inside a

Another type of boiler similar to and later than the du Temple boiler was the Yarrow boiler, which usually dispensed with external down-comer tubes after its designer,

A Reed boiler could be designed to operate at internal pressures of up to 300

Production and use

Reed water tube boilers were a "speciality" of the engine works at Palmers, which was capable of producing one "heavy marine boiler" a week, besides "a large number of water tube boilers".

See also

References

Footnotes

- ^ Palmers supplemented its own supply of iron ore with higher grade, hematite ore from Spain.[6]

- ^ "[I]t is worth noting that the first set of triple-expansion engines used in the British Navy were made in these works."[8]

- torpedo boat destroyer HMS Lightning of 1895, provision is illustrated for 694 steam-generating tubes.[10]

- ^ A more comprehensive assessment of the advantages of water tube boilers in naval vessels was published in Page's Magazine in 1902: "On making a careful comparison between water-tube and [fire-tube] boilers, we find that the former will raise steam more quickly and maintain it more evenly and at much greater pressure. They can be much more easily renewed or repaired, without having to lay up the ship or pull up her decks for this purpose. They are not so dangerous in action, and will not suffer so seriously from small projectiles. The effect on the ship's company will not be so disastrous in the event of an explosion, because they contain only a very small amount of water for steam generation. They are very much lighter and produce more horse-power per ton of weight, and thus enable advantages to be secured either in speed of vessel or in the amount of armour, armament, or coal supply. They can be "forced" or made to produce a greater quantity of steam for longer periods, and can therefore continue steaming at higher powers, and in this connection also they are assisted by a larger fire-grate area, which enables them to maintain steam for their maximum powers with greater facility."[12]

- ^ In HMS Lightning and HMS Janus, both of 1895, "there [were] in all upwards of 30,000 [of these] joints, and though they [had] been many times under steam, not a single leak ... occurred."[17]

- ^ HMS Pegasus, built by Palmers and launched in 1897, had eight Reed boilers, and was disabled when her condensers leaked and allowed sea water into her boilers.[29][30]

- ^ In Yarrow boilers groups of tubes were sometimes screened by baffles to create internal down-comers, or tubes might be used as stays that served the same purpose.[35]

- ^ The issue was contentious: while the inventor Hiram Maxim regarded down-comers as "utterly superfluous", the shipbuilder John Thornycroft regarded them as "indispensable".[37]

- ^ A plan of 1901 corrected to 28 September 1905 for the torpedo boat destroyer HMS Spiteful shows the arrangement and proportions of her four Reed boilers.[33]

- kilowatt hours of electricity per year.[46]

- ^ "The firm had originally offered to fit water tube boilers of their own design, but the Admiralty, presumably wary of an untried type of boiler, had offered for locomotive boilers instead. However, [they] proved quite inadequate ... on trials in the late summer and autumn of 1895. ... The builders [again] offered their own design but the Admiralty preferred to order Reed boilers from Palmer's."[54]

Notes

- ^ McFarland 1898, p. 427.

- ^ Dillon 1900, pp. 32–4.

- ^ Robertson 1901, p. 38.

- ^ a b "Model of a Joseph W. Reed water-tube boiler". Science Museum Group. n.d. Archived from the original on 13 February 2017. Retrieved 13 February 2017.

- ^ Cuthbert & Smith 2004, pp. 5 & 40.

- ^ a b Cuthbert & Smith 2004, p. 9.

- ^ Dillon 1900, pp. 31–6, esp. 32.

- ^ Dillon 1900, p. 36.

- ^ Robertson 1901, pp. 38, 126, 130, 136.

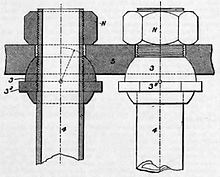

- ^ "Reed water tube boiler cross sections". Wikimedia Commons. 2017. Retrieved 17 February 2017.

- ^ Robertson 1901, pp. 2–3.

- ^ Anon. 1902b, pp. 423–5.

- ^ Robertson 1901, p. 130.

- ^ a b c Robertson 1901, p. 137.

- ^ Robertson 1901, pp. 136–7.

- ^ Busley 1902, p. 570.

- ^ a b c d e f g h Anon. 1896, p. 172.

- ^ Busley 1902, p. 563.

- ^ a b Robertson 1901, pp. 59–60.

- ^ Robertson 1901, pp. 126, 130, 136–7.

- ^ Busley 1902, p. 569.

- ^ Busley 1902, pp. 537, 568–9.

- ^ Liversidge 1906, p. 319.

- ^ Sennett & Oram 1899, p. 96.

- ^ Bertin 1906, p. 533.

- ^ Liversidge 1906, p. 367.

- ^ Robertson 1901, pp. 191–2.

- ^ Ritchie Leask 1892, pp. 189–91.

- ^ Robertson 1901, pp. 138–9.

- ^ Anon. 1899, p. 427.

- ^ Bertin 1906, p. 520.

- ^ Ritchie Leask 1892, pp. 191–2.

- ^ a b c "Plan of the ship HMS Spiteful (1899)". Royal Museums Greenwich. n.d. Archived from the original on 27 January 2017. Retrieved 13 February 2017.

- ^ Robertson 1901, pp. 55, 58, 152–4.

- ^ Robertson 1901, pp. 153–4.

- ^ Robertson 1901, p. 327.

- ^ Busley 1902, pp. 568–9.

- ^ Bertin 1906, p. 473.

- ^ Robertson 1901, p. 138.

- ^ Bertin 1906, p. 470.

- ^ Robertson 1901, pp. 139, 157.

- ^ Lyon 2005, pp. 78, 85.

- ^ Robertson 1901, p. 157.

- ^ Dillon 1900, p. 34.

- ^ Robertson 1901, p. 139.

- ^ "Typical domestic energy consumption figures" (PDF). ofgem. n.d. Archived (PDF) from the original on 21 January 2017. Retrieved 16 February 2017.

- ^ Dillon 1900, pp. 30–4.

- ^ Anon. 1893, p. 38.

- ^ a b Anon. 1932, p. 303.

- ^ Lyon 2005, pp. 77–81.

- ^ Anon. 1904, p. 27.

- ^ Anon. 1902a, p. 615.

- ^ Lyon 2005, pp. 75–6.

- ^ Lyon 2005, p. 75.

- ^ NID 1902, p. 413.

Bibliography

- Anon. (1893), "Hanoi", Engineering, 15: 38–9, OCLC 7540352

- Anon. (14 February 1896), "The Reed water-tube boiler" (PDF), The Engineer: 172, OCLC 5743177, archived from the original(PDF) on 14 February 2017, retrieved 14 February 2017

- Anon. (5 May 1899), "The naval boiler of the future" (PDF), The Engineer: 427–9, OCLC 5743177, archived from the original(PDF) on 14 February 2017, retrieved 14 February 2017

- Anon. (1902a), "Palmer's Shipbuilding and Iron Company, Jarrow-on-Tyne", Proceedings of the Institution of Mechanical Engineers: 613–6, OCLC 863604422

- Anon. (1902b), "Water-tube boilers, from a naval point of view", Page's Magazine, 1 (4): 423–5, OCLC 981215806

- Anon. (1904), "The British Admiralty ...", Scientific American, 91 (2): 27, ISSN 0036-8733

- Anon. (18 March 1932), "The late Mr J. W. Reed" (PDF), The Engineer: 303, OCLC 5743177, archived from the original(PDF) on 15 February 2017, retrieved 15 February 2017

- OCLC 752935582

- Busley, C. (1902), The Marine Steam Engine: Its Construction, Action and Management, vol. 1, translated by Cole, H.A.B. (3rd ed.), Lipsius & Tischer, OCLC 557623871

- Cuthbert, J.; Smith, K. (2004), Palmers of Jarrow 1851 – 1933, Tyne Bridge Publishing, ISBN 1-857951-96-4

- Dillon, M. (1900), Some Account of the Works of Palmers Shipbuilding & Iron Company Limited, Franklin, OCLC 68103311

- Liversidge, J.G. (1906), Engine-Room Practice A Handbook for the Royal Navy and Mercantile Marine: Treating of the Management of the Main and Auxiliary Engines on Board Ship (5th ed.), Griffin, OCLC 266076180

- Lyon, D. (2005) [1996], The First Destroyers, Mercury, ISBN 1-84560-010-X

- McFarland, W.M. (1898), "The Status of the Water-Tube Boiler in the American Marine", The Engineering Magazine, 14: 411–35, OCLC 265473122

- OCLC 981215806

- Ritchie Leask, A. (1892), Triple and Quadruple Expansion Engines and Boilers and Their Management, Tower, OCLC 266994925

- Robertson, L.S. (1901), Water-Tube Boilers: Based on a Short Course of Lectures Delivered at University College, London, Murray, OCLC 5640870

- Sennett, R.; Oram, H.J. (1899), The Marine Steam Engine: A Treatise for Engineering Students, Young Engineers, and Officers of the Royal Navy and Mercantile Marine (4th ed.), Longmans, Green, OCLC 36345208