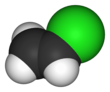

Vinyl chloride

| |||

| |||

| Names | |||

|---|---|---|---|

| Preferred IUPAC name

Chloroethene | |||

| Other names

Vinyl chloride monomer

VCM Chloroethylene Refrigerant-1140 | |||

| Identifiers | |||

3D model (

JSmol ) |

|||

| 1731576 | |||

| ChEBI | |||

| ChEMBL | |||

| ChemSpider | |||

ECHA InfoCard

|

100.000.756 | ||

| EC Number |

| ||

| 100541 | |||

| KEGG | |||

PubChem CID

|

|||

RTECS number

|

| ||

| UNII | |||

| UN number | 1086 | ||

CompTox Dashboard (EPA)

|

|||

| |||

| |||

| Properties | |||

| C2H3Cl | |||

| Molar mass | 62.50 g·mol−1 | ||

| Appearance | Colorless gas | ||

| Odor | pleasant[1] | ||

| Density | 0.911 g/cc | ||

| Melting point | −153.8 °C (−244.8 °F; 119.3 K) | ||

| Boiling point | −13.4 °C (7.9 °F; 259.8 K) | ||

| 2.7 g/L (0.0432 mol/L) | |||

| Vapor pressure | 2580 mmHg at 20 °C (68 °F) | ||

| -35.9·10−6 cm3/mol | |||

| Thermochemistry | |||

Heat capacity (C)

|

0.8592 J/K/g (gas) 0.9504 J/K/g (solid) | ||

Std enthalpy of (ΔfH⦵298)formation |

−94.12 kJ/mol (solid) | ||

| Hazards | |||

| GHS labelling: | |||

| |||

| Danger | |||

| H220, H350 | |||

| P201, P202, P210, P281, P308+P313, P377, P381, P403, P405, P501 | |||

| NFPA 704 (fire diamond) | |||

| Flash point | −61 °C (−78 °F; 212 K) | ||

Explosive limits

|

3.6–33%[1] | ||

| NIOSH (US health exposure limits): | |||

PEL (Permissible)

|

TWA 1 ppm C 5 ppm [15-minute][1] | ||

REL (Recommended)

|

Ca[1] | ||

IDLH (Immediate danger) |

Ca [N.D.][1] | ||

| Related compounds | |||

Related chloroethenes

|

dichloroethylenes, trichloroethylene, tetrachloroethylene

| ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |||

Vinyl chloride is an

Uses

Vinyl chloride, also called vinyl chloride monomer (VCM), is exclusively used as a precursor to PVC. Due to its toxic nature, vinyl chloride is not found in other products. Poly(vinyl chloride) (PVC) is very stable, storable and not toxic.[2]

Until 1974, vinyl chloride was used in

Production

To give a sense of scale, globally approximately 40 million tonnes of PVC resin are produced per year.[10] requiring a corresponding amount of vinyl chloride monomer.[11]

History

Vinyl chloride was first synthesized in 1835 by Justus von Liebig and his student Henri Victor Regnault. They obtained it by treating 1,2-dichloroethane with a solution of potassium hydroxide in ethanol.[12]

Acetylene-based routes

In 1912, Fritz Klatte, a German chemist working for Griesheim-Elektron, patented a means to produce vinyl chloride from

- C2H2 + HCl → CH2=CHCl

The reaction is exothermic and highly selective. Product purity and yields are generally very high.[2]

This route to vinyl chloride was common before ethylene became widely distributed. When vinyl chloride producers shifted to using the thermal cracking of EDC described below, some used byproduct HCl in conjunction with a colocated acetylene-based unit. The hazards of storing and shipping acetylene meant that the vinyl chloride facility needed to be located very close to the acetylene generating facility. China still uses this method to produce vinyl chloride due to the large reserves of coal from which acetylene is produced.[3][2]

In view of mercury's toxicity, gold- and platinum-based catalysts have been proposed.[13][14] This method was widely used during the 1930s and 1940s in the West.

Ethylene-based routes

In the United States and Europe, mercury-catalyzed routes have been superseded by more economical and greener processes based on ethylene. Ethylene is made by cracking ethane. Two steps are involved, chlorination and dehydrochlorination:

- H2C=CH2 + Cl2 → H2ClC−CH2Cl

- H2ClC−CH2Cl → H2C=CHCl + HCl

Possible routes from ethane

Numerous attempts have been made to convert ethane directly to vinyl chloride.[2] Ethane, which is even more readily available than ethylene, is a potential precursor to vinyl chloride. The conversion of ethane to vinyl chloride has been demonstrated by various routes:[2]

High-temperature chlorination:

- H3C−CH3 + 2 Cl2 → H2C=CHCl + 3 HCl

High-temperature oxychlorination, which uses oxygen and hydrogen chloride in place of chlorine:

- H3C−CH3 + O2 + HCl → H2C=CHCl + 2 H2O

High-temperature oxidative chlorination: 4 H3C−CH3 + 3 O2 + 2 Cl2 → 4 H2C=CHCl + 6 H2O

Thermal decomposition of dichloroethane

1,2-Dichloroethane, ClCH2CH2Cl (also known as ethylene dichloride, EDC), can be prepared by halogenation of ethane or ethylene, inexpensive starting materials. EDC thermally converts into vinyl chloride and anhydrous HCl. This production method has become the major route to vinyl chloride since the late 1950s.[2]

- ClCH2−CH2Cl → CH2=CHCl + HCl

The thermal cracking reaction is highly endothermic, and is generally carried out in a fired heater. Even though residence time and temperature are carefully controlled, it produces significant quantities of chlorinated hydrocarbon side products. In practice, the yield for EDC conversion is relatively low (50 to 60 percent). The furnace effluent is immediately quenched with cold EDC to minimize undesirable side reactions. The resulting vapor-liquid mixture then goes to a purification system. Some processes use an absorber-stripper system to separate HCl from the chlorinated hydrocarbons, while other processes use a refrigerated continuous distillation system.[2]

Storage and transportation

Vinyl chloride is stored as a liquid. The accepted upper limit of safety as a health hazard is 500 ppm. Often, the storage containers for the product vinyl chloride are high capacity spheres. The spheres have an inside sphere and an outside sphere. Several inches of space separate the inside sphere from the outside sphere. The interstitial space between the spheres is purged with an inert gas such as nitrogen. As the nitrogen purge gas exits the interstitial space it passes through an analyzer that detects whether any vinyl chloride is leaking from the internal sphere. If vinyl chloride starts to leak from the internal sphere or if a fire is detected on the outside of the sphere then the contents of the sphere are automatically dumped into an emergency underground storage container. Containers used for handling vinyl chloride at atmospheric temperature are always under pressure. Inhibited vinyl chloride may be stored at normal atmospheric conditions in suitable pressure vessels. Uninhibited vinyl chloride may be stored either under refrigeration or at normal atmospheric temperature in the absence of air or sunlight but only for a duration of a few days. If stored for longer periods, regular checks must be made to confirm no polymerization has taken place.

In addition to its toxicity risk, transporting vinyl chloride also presents the same risks as transporting other flammable gases such as propane, butane, or natural gas.

Fire and explosion hazard

In the U.S.,

Health effects

Since it is a gas under most ambient conditions, primary exposure is via inhalation, as opposed to the consumption of contaminated food or water, with occupational hazards being highest. Prior to 1974, workers were commonly exposed to 1,000 ppm vinyl chloride, causing "vinyl chloride illness" such as

Vinyl chloride is a mutagen having

Vinyl chloride can have acute dermal and

Liver toxicity

The

Vinyl chloride is now an IARC group 1 carcinogen known to cause hepatic angiosarcoma (HAS) in highly exposed industrial workers.[41] Vinyl chloride monomer, a component in the production of poly(vinyl chloride) (PVC) resins, is a halogenated hydrocarbon with acute toxic effects, as well as chronic carcinogenic effects.[42]

Cancerous tumors

Animals exposed to 30,000 ppm of vinyl chloride developed cancerous tumors. Studies on vinyl chloride workers were a "red flag" to B.F. Goodrich and the industry.[43] In 1972, Maltoni, another Italian researcher for the European vinyl chloride industry, found liver tumors (including angiosarcoma) from vinyl chloride exposures as low as 250 ppm for four hours a day.[44]

In 1997 the U.S. Centers for Disease Control and Prevention (CDC) concluded that the development and acceptance by the PVC industry of a closed loop polymerization process in the late 1970s "almost completely eliminated worker exposures" and that "new cases of hepatic angiosarcoma in vinyl chloride polymerization workers have been virtually eliminated."[45]

The Houston Chronicle claimed in 1998 that the vinyl industry manipulated vinyl chloride studies to avoid liability for worker exposure and hid extensive and severe chemical spills in local communities.[46]

Environment pollution

According to the

Mechanism

The carcinogenicity of VC is attributed to the action of two metabolites,

Microbial remediation

The bacteria species Nitrosomonas europaea can degrade a variety of halogenated compounds including trichloroethylene, and vinyl chloride.[49]

See also

- Vinyl group

- List of refrigerants, for R-1140

- 2023 Ohio train derailment, in which a large amount of vinyl chloride was spilled

References

Additional references for environmental pollution

- International Programme on Chemical Safety (IPCS) (1999). Vinyl chloride. Environmental Health Criteria 215. WHO, Geneva.

- National Poisons Information Service (NPIS) (2004). "Vinyl chloride." TOXBASE®.

- World Health Organisation (WHO) (2000). "Air quality guidelines for Europe." WHO Regional Publications, European Series, No. 91. 2nd edition. WHO Regional Office for Europe. Copenhagen.

- Hathaway G.J. and Proctor N.H. (2004). Chemical Hazards of the Workplace. 5th edition. John Wiley & Sons, New Jersey.

- Risk Assessment Information System (RAIS) (1993). "Toxicity summary for vinyl chloride. "Chemical Hazard Evaluation and Communication Group, Biomedical and Environmental Information Analysis Section, Health and Safety Research Division.

Inline citations

- ^ a b c d e NIOSH Pocket Guide to Chemical Hazards. "#0658". National Institute for Occupational Safety and Health (NIOSH).

- ^ ISBN 978-3527306732.

- ^ a b "Vinyl Chloride Monomer (VCM) – Chemical Economics Handbook". S&P Global. Archived from the original on 18 August 2014. Retrieved 5 April 2018.

- ^ "Vinyl Chloride". Wisconsin Department of Health Services. 2018-01-30. Archived from the original on 2023-02-07. Retrieved 2023-02-07.

- from the original on February 21, 2023. Retrieved February 21, 2023.

- ^ a b "Vinyl Chloride Monomer (VCM)". Department of Climate Change, Energy, the Environment and Water. Archived from the original on 2023-02-06.

- ^ Markowitz, Gerald; Rosner, David (2013). Deceit and Denial: The Deadly Politics of Industrial Pollution. Berkeley, California Press: University of California Press. p. 185.[dead link]

- PMID 572591.

- from the original on 2023-02-15. Retrieved 2023-02-15.

- ^ "PVC applications". The European Council of Vinyl Manufacturers. Retrieved 2023-02-25.

- ^ "Investigating the Safety of Vinyl Chloride in PVC Pipes for Drinking Water. Plumbing Navigator". Plumbingnav. Grabowski, B. Retrieved April 12, 2023.

- ^ Regnault, H. V. (1835). "Sur la Composition de la Liqueur des Hollandais et sur une nouvelle Substance éthérée". Annales de Chimie et de Physique. 5858. Gay-Lussac & Arago: 301–320. Archived from the original on 2019-07-11. Retrieved 2019-07-11.

- S2CID 206655247.

- PMID 32292878.

- ^ "aseh.net" (PDF). Archived from the original (PDF) on 2013-10-20. Retrieved 2013-10-06.

- ^ "Vinyl Chloride Monomer (VCM) Production". The European Council of Vinyl Manufacturers. Archived from the original on 2019-01-07.

- ^ Orsagos, Patrick; Seewer, John (February 6, 2023). "Crews release toxic chemicals from derailed tankers in Ohio". Associated Press. Archived from the original on February 7, 2023. Retrieved February 14, 2023.

- ^ "Ohio catastrophe is 'wake-up call' to dangers of deadly train derailments". The Guardian. February 11, 2023. Archived from the original on February 13, 2023. Retrieved February 13, 2023.

- ^ "NTSB Issues Investigative Update on Ohio Train Derailment". National Transportation Safety Board. 2023. Archived from the original on February 19, 2023. Retrieved April 19, 2023.

- Environmental Protection Agency. 2023. Archived(PDF) from the original on February 17, 2023. Retrieved April 19, 2023.

- ^ "Aseh.net" (PDF). Archived from the original (PDF) on 2013-10-20. Retrieved 2013-10-06.

- ^ "Occupational Safety and Health Guideline for Vinyl Chloride"1988."

- PMID 5551110.

- ^ "Vinyl chloride: health effects, incident management and toxicology". www.gov.uk. Archived from the original on 10 February 2018. Retrieved 5 April 2018.

- ^ Harrison, Henrietta (2008). Vinyl chloride Toxicological overview, Health Protecction Agency, UK

- ^ a b c International Programme on Chemical Safety (IPCS) (1999). Vinyl chloride. Environmental Health Criteria 215. WHO. Geneva.

- ^ UK Department for Environment, Food, and Rural Affairs (DEFRA) and Environment Agency (EA) (2004). "Contaminants in soil: Collation of toxicological data and intake values for humans. Vinyl chloride."

- ^ U.S. Department of Health and Human Services. Archived(PDF) from the original on 2023-02-15. Retrieved 2023-02-07.

- ^ International Agency for Research on Cancer (IARC). "Vinyl chloride, polyvinyl chloride, and vinyl chloride-vinyl acetate copolymers." Vol 19, 1979. IARC. "Vinyl chloride." Supplement 7, 1987. Lyon.

- from the original on 2020-02-09. Retrieved 2023-02-08.

- ^ Tribukh, S L et al. "Working Conditions and Measures for Their Improvement in Production and Use of Vinylchloride Plastics" (1949)

- ^ Wilson, Rex H et al. "Toxicology of Plastics and Rubber – Plastomers and Monomers." Reprinted from Industrial Medicine and Surgery. 23:11, 479–786. November 1954.

- from the original on 2023-02-18. Retrieved 2023-02-07.

- S2CID 30706677.

- ^ Kramer, G.C., M.D. "The Correlation of Clinical and Environmental Measurements for Workers Exposed to Vinyl Chloride." The Dow Chemical Company. Midland Michigan.

- ^ Viola, P.L. "Pathology of Vinyl Chloride" International Congress on Occupational Health. Japan. 1969.

- PMID 6360677.

- ISBN 978-0-87969-119-6.

- PMID 6800782.

- PMID 6360677.

- PMID 16002366.

- ^ PMC, Europe. "Europe PMC". europepmc.org. Retrieved 2023-02-18.

- ^ Viola, P L. "Carcinogenic Effect of Vinyl Chloride" Presented at the Tenth International Cancer Congress. Houston, Texas. May 22–29, 1970.

- ^ Maltoni, C. "Cancer Detection and Prevention" (1972) Presented at the Second International Symposium on Cancer Detection and Prevention. Bologna, April 9–12, 1973.

- ^ Epidemiologic Notes and Reports Angiosarcoma of the Liver Among Polyvinyl Chloride Workers – Kentucky Archived 2010-09-16 at the Wayback Machine. Centers for Disease Control and Prevention. 1997.

- ^ Jim Morris, "In Strictest Confidence. The chemical industry's secrets," Houston Chronicle. Part One: "Toxic Secrecy," June 28, 1998, pp. 1A, 24A–27A; Part Two: "High-Level Crime," June 29, 1998, pp. 1A, 8A, 9A; and Part Three: "Bane on the Bayou," July 26, 1998, pgs. 1A, 16A.

- ^ National Emission Standards for Hazardous Air Pollutants (NESHAP) for Vinyl Chloride Subpart F, OMB Control Number 2060-0071, EPA ICR Number 0186.09 (Federal Register: September 25, 2001 (Volume 66, Number 186) Archived March 22, 2003, at the Wayback Machine)

- ^ EPA Toxicological Review of Vinyl Chloride in Support of Information on the IRIS. May 2000

- ^ "Home – Nitrosomonas europaea". genome.jgi-psf.org. Archived from the original on 3 July 2009. Retrieved 5 April 2018.

Further reading

- "Medicine: The Plastic Peril". Time. May 13, 1974. Archived from the original on June 12, 2007. Retrieved 2 July 2010.