Yeast in winemaking

The role of yeast in winemaking is the most important element that distinguishes

The most common yeast associated with

History

For most of the history of wine, winemakers did not know the mechanism that somehow converted sugary grape juice into alcoholic wine. They could observe the fermentation process which was often described as "boiling", "seething" or the wine being "troubled" due to release of carbon dioxide that gave the wine a frothy, bubbling appearance. This history is preserved in the etymology of the word "yeast" itself which essentially means "to boil".[3][6]

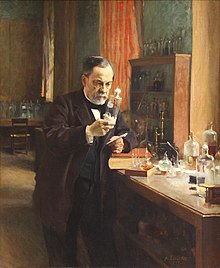

In the mid-19th century, the French scientist

The yeast species commonly known as Saccharomyces cerevisiae was first identified in late 19th century enology text as Saccharomyces ellipsoideus due to the

In modern winemaking, winemakers have the option to select from a diverse range of yeast strains, each offering distinct characteristics that influence the wine's sensory profile. These strains are readily available for purchase from specialized suppliers.[8] Winemakers can now easily access yeast strains that accentuate desirable features in wine, such as aromatic compounds, mouthfeel, and fermentation kinetics. This commercial availability of yeast strains has revolutionized the art of winemaking by allowing for more precise control over the fermentation process and the resultant wine's character.

Role in winemaking

The primary role of yeast is to convert the sugars present (namely

Other compounds in wine produced by yeast

While the production of alcohol is the most noteworthy by-product of yeast metabolism from a winemaking perspective, there are a number of other products that yeast produce that can be also influence the resulting wine. This includes

Other by-products of yeast include:[3][10]

- pectinsin the must by enzymes of the yeast. More commonly found in red wines than white but only in very small amounts between 20–200 mg/L.

- Fusel oils – Formed by the decomposition of amino acids by the yeast. This includes 2,3-Butanediol which is formed by yeast that are consuming diacetyl, the compound that gives Chardonnay and other wines a "buttery" aroma, reducing it first to acetoin and then to the more neutral-smelling 2,3-Butanediol. Many beer and winemakers who have a wine with too much "butteriness" will often "pitch" fresh yeast cultures into the no longer fermenting tank so that the yeast will consume the diacetyl and reduce the aroma.[11]

- acidity of wine.

- volatile acidity that can make a wine taste unbalanced and overly acidic. While acetic acid is the main volatile acid produced by yeast, trace amounts of butyric, formic and propionic acids can also be formed depending on the yeast strain. Most countries have wine laws setting the legal limit of volatile acidity, usually expressed as acetic acid, to 1200–2000 mg/L. Acetic acid can also lead to the development of the wine fault ethyl acetate which is characterized by a "nail polish remover" smell. However, small amounts of acetic acid are actually beneficial for the yeast as they use them to synthesis lipids in the cell membrane.[3]

- oxidized aromas.[3]

- ethyl mercaptans and disulfides that contribute to off aromas and wine faults. Some commercial yeast strains, such as Montrachet 522 are known to produce higher levels of hydrogen sulfides than other strains, particularly if the must has some nutrient deficiencies.[1]

- anthocyanins extracted from contact with grape skins to create a more stable color pigment (pyranoanthocyanin) that can enhance the color of some red wines.[3]

- Various acetals.[2]

Lees

When yeast cells die, they sink to the bottom of the fermentation vessel where they combine with insoluble

The process of leaving the wine to spend some contact with the lees has a long history in winemaking, being known to the

Most of the benefits associated with lees contact deals with the influence on the wine of the mannoproteins released during the autolysis of the yeast cells. Composed primarily of

Secondary fermentation

The production of Champagne and many sparkling wines requires a second fermentation to occur in the bottle in order to produce the carbonation necessary for the style. A small amount of sugared liquid is added to individual bottles, and the yeast is allowed to convert this to more alcohol and carbon dioxide. The lees are then ricked into the neck of the bottle, frozen, and expelled via pressure of the carbonated wine.

Types of yeasts used in winemaking

Yeast

The most common yeast generally associated with winemaking is Saccharomyces cerevisiae which is also used in

- Brettanomyces (Teleomorph Dekkera)

- Candida (Teleomorphs for different species from several genera including Pichia, Metschnikowia, Issatchenkia, Torulaspora and Kluyveromyces)

- Kloeckera (Teleomorph Hanseniaspora), usually the most common "wild yeast" found in the vineyard. Some species are known as "killer yeast" that produce inhibitory levels of ethyl acetate and acetic acid that can kill off sensitive strains of Saccharomyces cerevisiae[5]

- Saccharomycodes

- Schizosaccharomyces, the only wine yeast that reproduced by fission whereas most wine yeast reproduce by budding.[4]

- Zygosaccharomyces, very alcohol-tolerant and can grow in wines up to 18% v/v. Additionally this yeast can survive in extremely high sugar levels (as much as 60% w/w or 60 Brix) and is very resistant to sulfur dioxide.[4]

- aging wine in barrels.[4]

Saccharomyces

The yeast genus Saccharomyces (sugar mold) is favored for winemaking (for both grapes as well as other

In addition to Saccharomyces cerevisiae, other species within the genus Saccharomyces that are involved with winemaking include:[1][3][4]

- Saccharomyces bayanus

- Saccharomyces beticus

- Saccharomyces fermentati

- Saccharomyces paradoxus

- Saccharomyces pastorianus

- Saccharomyces uvarum

Influences of different strains on fermentation

In 1996, Saccharomyces cerevisiae was the first single-celled,

Some distinct difference among various strains include the production of certain "off-flavor" and aromas that may be temporary (but producing a "stinky fermentation") or could stay with the wine and either have to be dealt with through other winemaking means (such as the presence of volatile sulfur compounds like hydrogen sulfide) or leave a faulty wine. Another difference includes the "vigor" or speed of fermentation (which can also be influenced by other factors beyond yeast selection) with some yeast strains having the tendency to do "fast ferments" while others may take longer to get going.[3]

Another less measurable difference that are subject to more debate and questions of winemakers preference is the influence of strain selection on the

In

Wild yeasts and natural fermentation

In winemaking, the term "wild yeast" has multiple meanings. In its most basic context, it refers to yeast that has not been introduced to the must by intentional inoculation of a cultured strain. Instead, these "wild yeasts" often come into contact with the must through their presence on harvest equipment, transport bins, the surface winemaking equipment and as part of the natural flora of a winery. Very often these are strains of Saccharomyces cerevisiae that have taken residence in these places over the years, sometimes being previously introduced by inoculation of prior vintages. In this context, these wild yeasts are often referred to as ambient, indigenous or natural yeast as opposed to inoculated, selected or cultured yeast. Wineries that often solely rely on these "in-house" strains will sometimes market their wines as being the product of wild or natural fermentations.[3] The (c. 304) Nanfang Caomu Zhuang has the earliest description of winemaking using "herb ferment" (cǎoqū 草麴) wild yeast with rice and various herbs, including the poisonous Gelsemium elegans (yěgé 冶葛).[13][14]

Another use of the term "wild yeast" refers to the non-Saccharomyces genera of yeasts that are present in the vineyard, on the surface of

Unlike the "ambient" Saccharomyces wild yeast, these genera of wild yeasts have very low tolerance to both alcohol and sulfur dioxide. They are capable of starting a fermentation and often begin this process as early as the harvest bin when clusters of grapes get slightly crushed under their own weight. Some winemakers will try to "knock out" these yeasts with doses of sulfur dioxide, most often at the crusher before the grapes are

The use of both "ambient" and non-Saccharomyces wild yeasts carries both potential benefits and risk. Some winemakers feel that the use of resident/indigenous yeast helps contribute to the unique expression of

It is virtually inevitable that non-Saccharomyces wild yeast will have a role in beginning the fermentation of virtually every wine but for the wineries that choose to allow these yeasts to continue fermenting versus minimizing their influence do so with the intent of enhancing complexity through bio-diversity. While these non-Saccharomyces ferment glucose and fructose into alcohol, they also have the potential to create other intermediates that could influence the aroma and flavor profile of the wine. Some of these intermediates could be positive, such as phenylethanol, which can impart a rose-like aroma.[5] However, as with ambient yeasts, the products of these yeasts can be very unpredictable – especially in terms of the types of flavors and aromas that these yeasts can produce.[3]

Inoculated yeast

When winemakers select a cultured yeast strain, it is largely done because the winemaker wants a predictable fermentation taken to completion by a strain that has a track record of dependability. Among the particular considerations that are often important to winemakers is a yeast's tendency to:[5]

- Quickly begin fermentation, out-competing other "wild yeasts" for nutrients in the must

- Completely utilize all fermentable sugars with a predictable sugar-to-alcohol conversion rate

- Have an alcohol-tolerance up to 15% or even higher depending on the winemaking style

- Have a high sulfur dioxide tolerance but low production of sulfur compounds such as hydrogen sulfide or dimethyl sulfide

- Produce a minimum amount of residual pyruvate, acetic acid and acetaldehyde

- Produce minimum foaming during fermentation which may create difficulties for cap management during barrelfermentation.

- Have high levels of fining and filteringof the wine easier.

Inoculated (or pure cultured) yeasts are strains of Saccharomyces cerevisiae that have been identified and plated from wineries across the world (including notable producers from well-known wine regions such as

Re-hydrating freeze dried yeast cultures

Pure culture yeasts that are grown in a lab are often

Similarly, re-hydration procedures will also vary depending on the manufacturer and winery. Yeast is often inoculated in a volume of water or grape must that is 5–10 times the weight of the dry yeast. This liquid is often brought to temperature of 40 °C (104 °F) prior to the introduction of the yeast (though some yeast strains may need temperatures below 38 °C (100 °F)

The temperature of the starter culture is then slowly reduced, often by the graduated addition of must to get within 5–10 °C (9–18 °F) of the must that the culture will be added to. This is done to avoid the sudden cold shock that the yeast cells may experience if the starter culture was added directly to the must itself which can kill up to 60% of the culture. Additionally, surviving cells exposed to cold shock tend to see an increase in hydrogen sulfide production.[5]

Nutritional needs of wine yeast

In order to successfully complete a fermentation with minimum to no negative attributes being added to the wine, yeast needs to have the full assortment of its nutritional needs met. These include not only an available energy source (carbon in the form of sugars such as glucose) and

- phospholipids (an important component of the cell membrane) and ATP (Adenosine triphosphatewhich the cell uses for transferring energy for metabolism).

- Potassium – important for the uptake and utilization of phosphate

- fatty acidsand nucleic acids.

- Pantothenic acid – involved in the metabolism of sugars and lipids. A deficiency of this vitamin could lead into increase hydrogen sulfide production with off-aromas in the resulting wine.

- Nicotinic acid – involved in the synthesis of Nicotinamide adenine dinucleotide (NAD+), a co-enzyme that is important in maintaining the redox balance of the cell as well as in the process of ethanol fermentationitself.

- secondary messenger molecules that facilitate cell division.

- Trace amounts of calcium, chlorine, copper, iron, manganese and zinc for healthy cell function.

Many of these nutrients are available in the must and skins of the grapes themselves but sometimes are supplemented by winemakers with additions such as

Saccharomyces cerevisiae can assimilate nitrogen from both inorganic (ammonia and

The role of oxygen

Yeasts are

Cultured yeasts that are freeze-dried and available for inoculation of wine must are deliberately grown in commercial labs in high oxygen/low sugar conditions that favor the development of these survival factors. One of the reasons that some winemakers prefer using inoculated yeast is the predictability of fermentation due to the high level of survival factors that cultured yeast are assured of having without necessarily needing to expose the wine to additional levels of oxygen. Winemakers using "ambient" yeasts that are resident in their winery may not have this same assurance of survival factors and may need to compensate with other winemaking techniques.[4]

Wild non-Saccharomyces yeasts often need a much greater exposure to oxygen in order to build up survival factors which is why many of these yeasts are often found living oxidatively as "film yeast" on the surface of wines in tanks or barrels.[4]

Either directly or indirectly, wine yeast can be a culprit behind a wide variety of

In the presence of

Growth of many unfavorable wild yeasts is generally slowed at lower cellar temperatures, so many winemakers who wish to inhibit the activities of these yeasts before the more favorable Saccharomyces yeast kick in, will often chill their must, such as the practice of "cold soaking" the must during a pre-fermentation maceration at temperatures between 4–15 °C (39–50 °F). Though some species, such as Brettanomyces, will not be inhibited and may even thrive during an extended period of cold soaking.[5]

Brettanomyces

The wine yeast Brettanomyces (or "Brett") produces very distinctive aroma compounds,

As a fermentation yeast, Brettanomyces can usually ferment a wine up to 10–11% alcohol levels before they die out. Sometimes Brettanomyces already present in a wine that has been inoculated with Saccharomyces cerevisiae will out compete the Saccharomyces strain for nutrients and even inhibit it due to the high levels of acetic acid,

Once Brett is in a winery, it is very difficult to control even with strict hygiene and the discarding of barrels and equipment that has previously come into contact with "Bretty" wine. This is because many species of Brettanomyces can use a wide variety of carbon sources in wine and grape must, including ethanol, for metabolism. Additionally, Brett can produce a wide range of by-products that could influence the wine beyond just the 4-EP and 4-EG compounds previously discussed.[4] Many of these compounds, such as the "footprints" of the 4-EP and 4-EG, will still remain in the wine even after yeast cells die and are removed by racking and sterile filtration.[5]

References

- ^ ISBN 1580171052

- ^ ISBN 1891267914

- ^ ISBN 0198609906

- ^ ISBN 0387333495

- ^ ISBN 0834217015

- ^ Douglas Harper "Yeast" Online Etymology Dictionary Accessed: May 31st, 2012

- ISBN 0198609906

- ^ "Wine Yeast". Scott Labs. Retrieved 23 August 2023.

- ^ ISBN 0834217015

- ^ ISBN 0932664660

- ^ Brewing Science "Diacetyl: Homebrew Science Archived 2010-02-02 at the Wayback Machine" Brew Magazine November, 2002

- ^ ISBN 0198609906

- ^ Joseph Needham and Huang Hsing-Tsung (2000), Science and Civilisation in China, Volume 6 Biology and Biological Technology, Part 5: Fermentations and Food Science, Cambridge University Press, p. 183.

- ^ Li Hui-Lin (1979), Nan-fang ts'ao-mu chuang: a fourth century flora of Southeast Asia, The Chinese University Press, p. 59.

- ISBN 0932664695

External links

- P. Romano, C. Fiore, M. Paraggio, M. Caruso, A. Capece "Function of yeast species and strains in wine flavour". Archived 2015-06-06 at the Wayback Machine. International Journal of Food Microbiology 86 (2003). pp. 169–180.