Hollow fiber membrane

Hollow fiber membranes (HFMs) are a class of artificial membranes containing a semi-permeable barrier in the form of a hollow fiber. Originally developed in the 1960s for reverse osmosis applications, hollow fiber membranes have since become prevalent in water treatment, desalination, cell culture, medicine, and tissue engineering.[1] Most commercial hollow fiber membranes are packed into cartridges which can be used for a variety of liquid and gaseous separations.

Manufacturing

HFMs are commonly produced using

- Melt Spinning, in which a thermoplastic polymer is melted and extruded through a spinneret into air and subsequently cooled.[2]

- Dry Spinning, in which a polymer is dissolved in an appropriate solvent and extruded through a spinneret into air.[3]

- Dry-Jet Wet Spinning, in which a polymer is dissolved in an appropriate solvent and extruded into air and a subsequent coagulant (usually water).[3]

- Wet spinning, in which a polymer is dissolved and extruded directly into a coagulant (usually water).[3]

Common to each of these methods is the use of a

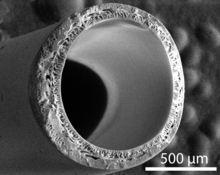

Characterization

The properties of HFMs can be characterized using the same techniques commonly used for other types of membranes. The primary properties of interest for HFMs are average pore diameter and pore distribution, measurable via a technique known as

Depending on the diameters of pores in an HFM, scanning electron microscopy or transmission electron microscopy can be used to yield a qualitative perspective of pore size.Applications

Hollow fiber membranes are ubiquitously used in industrial separations, especially the filtration of drinking water.[9]

Industrial water filters are mainly equipped with ultrafiltration hollow fiber membranes. Domestic water filtration systems have microfiltration hollow fiber membranes. In microfiltration a membrane pore diameter of 0.1 micrometers cuts-off microorganisms like germs and bacteria, Giardia cysts and other intestinal parasites, as well removing sediments. Ultrafiltration membranes are capable of removing not only bacteria, but also viruses.

Hollow fibers are commonly used substrates for specialized bioreactor systems, with the ability of some hollow fiber cartridges to culture billions of anchorage-dependent cells within a relatively low (<100 mL) bioreactor volume.[10]

Hollow fibers can be used for drug efficacy testing in cancer research, as an alternative to the traditional, but more expensive, xenograft model.[11]

Hollow fiber membranes are used in Membrane oxygenators in extracorporeal membrane oxygenation which oxygenates blood, replacing lungs in critically ill patients.

See also

- Membrane

- List of synthetic polymers

- Reverse Osmosis

- Nanofiltration

- Ultrafiltration

- Microfiltration

References

- ISBN 978-1-84826-877-7.

- ISBN 9783319010953.

- ^ ISBN 9781597452786.

- .

- ^ A.B. Abell, K.L. Willis and D.A. Lange, "Mercury Intrusion Porosimetry and Image Analysis of Cement-Based Materials", Journal of Colloid and Interface Science, 211, pp. 39-44 (1999).

- .

- .

- ^ MBR-The reliable solution for difficult to treat Wastewaters (PDF). OWEA NE Industrial Waste Seminar. February 20, 2014.

- ISSN 0011-9164.

- PMID 26151065.

- ISSN 0959-8049.