Membrane fouling

Membrane fouling is a process whereby a

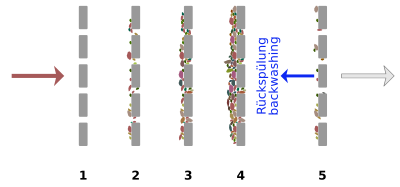

Fouling can be divided into reversible and irreversible fouling based on the attachment strength of particles to the membrane surface. Reversible fouling can be removed by a strong shear force or backwashing. Formation of a strong matrix of fouling layer with the solute during a continuous filtration process will result in reversible fouling being transformed into an irreversible fouling layer. Irreversible fouling is the strong attachment of particles which cannot be removed by physical cleaning.[7]

Influential factors

Factors that affect membrane fouling:

Recent fundamental studies indicate that membrane fouling is influenced by numerous factors such as system hydrodynamics, operating conditions,[8] membrane properties, and material properties (solute). At low pressure, low feed concentration, and high feed velocity, concentration polarisation effects are minimal and flux is almost proportional to trans-membrane pressure difference. However, in the high pressure range, flux becomes almost independent of applied pressure.[9] Deviation from linear flux-pressure relation is due to concentration polarization. At low feed flow rate or with high feed concentration, the limiting flux situation is observed even at relatively low pressures.

Measurement

Flux,[3] transmembrane pressure (TMP), Permeability, and Resistance are the best indicators of membrane fouling. Under constant flux operation, TMP increases to compensate for the fouling. On the other hand, under constant pressure operation, flux declines due to membrane fouling. In some technologies such as membrane distillation, fouling reduces membrane rejection, and thus permeate quality (e.g. as measured by electrical conductivity) is a primary measurement for fouling.[8]

Fouling control

Even though membrane fouling is an inevitable phenomenon during membrane filtration, it can be minimised by strategies such as cleaning, appropriate membrane selection and choice of operating conditions.

Membranes can be cleaned physically, biologically or chemically. Physical cleaning includes gas scour, sponges, water jets or backflushing using

Another strategy to minimise membrane fouling is the use of the appropriate membrane for a specific operation. The nature of the feed water must first be known; then a membrane that is less prone to fouling with that solution is chosen. For aqueous filtration, a hydrophilic membrane is preferred.[12] For membrane distillation, a hydrophobic membrane is preferred.[13]

Operating conditions during membrane filtration are also vital, as they may affect fouling conditions during filtration. For instance,

See also

References

- .

- PMID 29573825.

- ^ ISSN 0376-7388.

- ISSN 0011-9164.

- ISSN 0376-7388.

- ^ Baker, R.W. (2004). Membrane Technology and Applications, England: John Wiley & Sons Ltd

- ^ Choi, H., Zhang, K., Dionysiou, D.D.,Oerther, D.B.& Sorial, G.A. (2005) Effect of permeate flux and tangential flow on membrane fouling for wastewater treatment. J. Separation and Purification Technology 45: 68-78.

- ^ ISSN 0376-7388.

- ^ Ghosh, R., 2006, Principles of Bioseparation Engineering, World Scientific Publishing Pvt Ltd.

- ISSN 0011-9164.

- ISSN 2053-1400.

- ISSN 0149-6395.

- ISSN 0376-7388.