Three roll mill

This article includes a list of general references, but it lacks sufficient corresponding inline citations. (January 2012) |

A three roll mill or triple roll mill

The three-roll mill has proven to be the most successful of the range of roll mills which saw extensive development in the 19th century. These included the single-roll mill and the five-roll mill. The single-roll mill works by material passing between the roll and a fixed bar pressing against the roll. The five-roll mill incorporates four successively smaller in-running nips and hence, compared to the three-roll mill, allows the use of larger agglomerates as part of the input material- but is correspondingly more complicated and expensive.[2]

Operation of a three roll mill

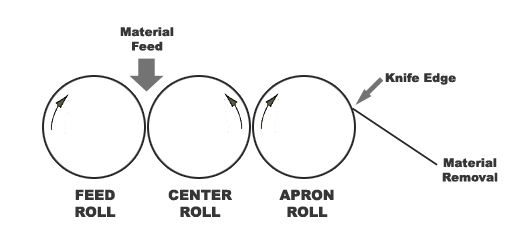

The three adjacent rolls of a three roll mill (called the feed roll, centre roll and apron roll) rotate at progressively higher speeds. Material, usually in the form of

The gaps between the rolls can be mechanically or

Application

Three roll mills are widely used to mix printing

Small bench models are used for bench-top development work, laboratory work, and low volume production. Larger bench and floor models are built to meet different production needs from pilot plants to large volume productions.

Particular advantages of this process are that it allows high-viscosity pastes to be milled, and that the high surface contact with the cooled rollers allow the temperature to remain low despite the high amount of dispersion work being put in. A notable disadvantage is that the large open area of paste on the rollers causes loss of volatiles.

References

- ISBN 0-7506-3760-9

- ISBN 978-1-44372-934-5

- ^ Harper, Charles A. (2004), Electronic Materials and Interconnection Handbook, New York: The McGraw-Hill Companies, Inc., pp. 570–571[full citation needed]

- ISBN 0-444-89723-2