Friction drive

This article needs additional citations for verification. (December 2013) |

A friction drive or friction engine is a type of

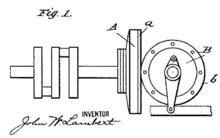

The system consists of two disks, normally metal, set at right angles to each other. One disk is connected to the engine, the other to the load. The load disk is positioned so that its outer rim is pressed against the driven disk, and normally has some sort of high-friction surface applied to the outer rim to improve torque transfer. In early systems, paper and leather was often used for this surface. One of the disks, normally the load side, is mounted on a shaft that allows it to be moved in relation to the driven disk, allowing it to move from a position at the center of the driven disk to its outer radius. Moving the load disk along this shaft changes the ratio of input to output speed; when the load disk is at the center the output is zero, when it is at the outer rim, it is the ratio of the radius of the two disks.

While mechanically simple and providing a variable transmission that requires no clutch, there are a number of problems with the design that limit its use. The first is that the amount of torque that can be transferred is a function of the contact patch between the two disks, and thus a function of the width of the load disk. Increasing this width improves torque handling, but then runs into a second problem. As the "gear ratio" is a function of the distance from the center of the driven disk, any finite thickness on the driven disk means the inner and outer edges are being driven at different speeds. This causes considerable friction on the bearing surface, wearing it out and giving off significant amounts of heat. This results in a sweet spot that limits it to certain low-torque roles.

In phonographs

Friction drive has been most successfully used in low-power applications, such as driving phonograph turntables.

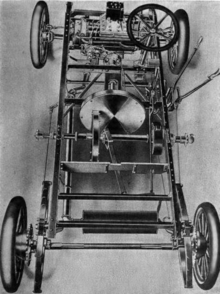

In automobiles

Automobiles using this drive system included the

In railway locomotives

Plymouth Locomotive Works's first three models, the AL, BL and CL were equipped with a friction drive.[1][2]

Early models of the

Belt drives

A belt drive is a form of friction drive but is usually categorized separately from the "disk and wheel" type of friction drive.

See also

- Contact mechanics – Study of the deformation of solids that touch each other

- Frictional contact mechanics – Study of the deformation of bodies in the presence of frictional effects

- Adhesion railway – Railway relying on adhesion to move trains

- Rolling (metalworking) – Metal forming process

- Toroidal or roller-based CVT (Extroid CVT) – Automotive transmission technology

- Tribology – Science and engineering of interacting surfaces in relative motion

References

- ^ US 1283665, Carter, Floyd B., "Locomotive", issued 1918-11-05

- ^ Trask, Chas. A. (June 1918). "Tractor Friction Transmissions". Journal of the Society of Automotive Engineers. II (6): 440. Page 444 discusses the Plymouth locomotive, with a drawing and photograph on page 445.

- ^ "Wickham Motor Trolley". South Devon Railway. April 5, 2013.

External links

- Animated image of a toroidal CVT on HowStuffWorks Archived 2019-01-10 at the Wayback Machine