Polysulfide

Polysulfides are a class of

Polysulfide salts and complexes

The alkali metal polysulfides arise by treatment of a solution of sulfide, e.g. sodium sulfide, with elemental sulfur:

S2−

+ n S → S2−

n+1

In some cases, these anions have been obtained as organic salts, which are soluble in organic solvents.[4]

The energy released in the reaction of sodium and elemental sulfur is the basis of battery technology. The sodium–sulfur battery and the lithium–sulfur battery require high temperatures to maintain liquid polysulfide and Na+-conductive membranes that are unreactive toward sodium, sulfur, and sodium sulfide.

Polysulfides are

Organic polysulfides

In commerce, the term "polysulfide" usually refers to a class of polymers with alternating chains of several sulfur atoms and hydrocarbons. They have the formula R1SnR2. In this formula n indicates the number of sulfur atoms (or "rank"). Polysulfide polymers can be synthesized by

n Na2S5 + n ClCH2CH2Cl → [CH2CH2S5]n + 2n NaCl

Dihalides used in this condensation polymerization are dichloroalkanes (such as 1,2-dichloroethane, bis-(2-chloroethoxy)methane and 1,3-dichloropropane). The polymers are called thiokols. In some cases, polysulfide polymers can be formed by ring-opening polymerization reactions.

Polysulfide polymers are also prepared by the addition of polysulfanes to alkenes. An idealized equation is:

2 RCH=CH2 + H2Sn → (RCH2CH2)2Sn

In reality, homogeneous samples of H2Sn are difficult to prepare.[2]

Polysulfide polymers are insoluble in water, oils, and many other organic solvents. Because of their solvent resistance, these materials find use as sealants to fill the joints in pavement, automotive window glass, and aircraft structures.

Polymers containing one or two sulfur atoms separated by hydrocarbon sequences are usually not classified polysulfides, e.g.

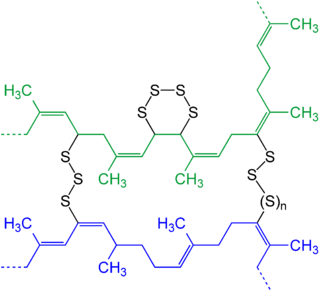

Polysulfides in vulcanized rubber

Many commercial

Occurrence in gas giants

In addition to water and ammonia, the clouds in the atmospheres of the gas giant planets contain ammonium sulfides. The reddish-brownish clouds are attributed to polysulfides, arising from the exposure of the ammonium sulfides to light.[7]

Properties

Polysulfides, like sulfides, can induce stress corrosion cracking in carbon steel and stainless steel.

See also

- Disulfide – Functional group with the chemical structure R−S−S−R′

- Trisulfide – Functional group

- Polyiodide – Anions composed of many iodine atoms

- Catenation – Bonding of atoms of the same element into chains or rings

References

- ISBN 978-0-08-096529-1, retrieved 2022-03-29

- ^ ISBN 978-0470860786.

- .

- .

- .

- ISBN 3-540-40378-7.

- ^ "Jupiter: Cloud composition". Encyclopædia Britannica. 6 June 2023.