Indium tin oxide

Indium tin oxide (ITO) is a

Indium tin oxide is one of the most widely used

Material and properties

ITO is a mixed oxide of

Common uses

Indium tin oxide (ITO) is an optoelectronic material that is applied widely in both research and industry. ITO can be used for many applications, such as flat-panel displays, smart windows, polymer-based electronics, thin film photovoltaics, glass doors of supermarket freezers, and architectural windows. Moreover, ITO thin films for glass substrates can be helpful for glass windows to conserve energy.[2]

ITO green tapes are utilized for the production of lamps that are electroluminescent, functional, and fully flexible.[3] Also, ITO thin films are used primarily to serve as coatings that are anti-reflective and for liquid crystal displays (LCDs) and electroluminescence, where the thin films are used as conducting, transparent electrodes.[4]

ITO is often used to make transparent conductive coating for displays such as

ITO films deposited on windshields are used for defrosting aircraft windshields. The heat is generated by applying a voltage across the film. ITO is also used to reflect or absorb electromagnetic radiation. The F-22 Raptor's canopy has an ITO coating that absorbs radar waves and reflects infrared waves, enhancing its stealth capabilities and giving it a distinctive gold tint.[5][6]

ITO is also used for various

ITO thin film strain gauges can operate at temperatures up to 1400 °C and can be used in harsh environments, such as gas turbines, jet engines, and rocket engines.[9]

Silver nanoparticle–ITO hybrid

ITO has been popularly used as a high-quality flexible substrate to produce flexible electronics.

Alternative synthesis methods

ITO is typically deposited through expensive and energy-intensive processes that deal with physical

Tape casting process

An alternative process that uses a particle-based technique, is known as the tape casting process. Because it is a particle-based technique, the ITO nano-particles are dispersed first, then placed in organic solvents for stability.

Laser sintering

Using ITO

Ambient gas conditions

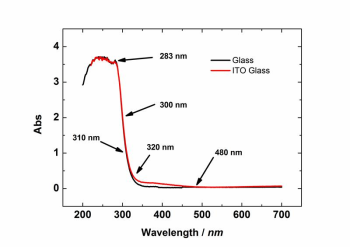

For example, using conventional methods but varying the ambient gas conditions to improve the optoelectronic properties[17] as, for example, oxygen plays a major role in the properties of ITO.[18]

Chemical shaving for very thin films

There has been numerical modeling of

Constraints and trade-offs

A major concern with ITO is its cost. ITO costs several times more than

While the sputtering target or evaporative material that is used to deposit the ITO is significantly more costly than AZO, the amount of material placed on each cell is quite small. Therefore, the cost penalty per cell is quite small, too.

Benefits

The primary advantage of ITO compared to AZO as a transparent conductor for

Another benefit of ITO compared to AZO is that if moisture does penetrate, ITO will degrade less than AZO.[20]

The role of ITO glass as a cell culture substrate can be extended easily, which opens up new opportunities for studies on growing cells involving

Research examples

ITO can be used in nanotechnology to provide a path to a new generation of solar cells. Solar cells made with these devices have the potential to provide low-cost, ultra-lightweight, and flexible cells with a wide range of applications. Because of the nanoscale dimensions of the nanorods, quantum-size effects influence their optical properties. By tailoring the size of the rods, they can be made to absorb light within a specific narrow band of colors. By stacking several cells with different sized rods, a broad range of wavelengths across the solar spectrum can be collected and converted to energy. Moreover, the nanoscale volume of the rods leads to a significant reduction in the amount of semiconductor material needed compared to a conventional cell.[23][24] Recent studies demonstrated that nanostructured ITO can behave as a miniaturized photocapacitor, combining in a unique material the absorption and storage of light energy.[25]

Health and safety

Inhalation of indium tin oxide may cause mild irritation to the

During the process of mining, production and reclamation, workers are potentially exposed to indium, especially in countries such as China, Japan, the Republic of Korea, and Canada

A new occupational problem called

Because of these issues, alternatives to ITO have been found.[32][33]

Recycling

The

Alternative materials

Because of high cost and limited supply of indium, the fragility and lack of flexibility of ITO layers, and the costly layer deposition requiring vacuum, alternative materials are being investigated.[14] Promising alternatives based on zinc oxide doped with various elements.[42]

Doped compounds

Promising alternatives based on zinc oxide doped with various elements.[43]

Several transition metal dopants in indium oxide, particularly molybdenum, give much higher electron mobility and conductivity than obtained with tin.

Carbon nanotubes

Carbon nanotube conductive coatings are a prospective replacement.[45][46]

Graphene

As another carbon-based alternative, films of

Conductive polymers

Inherently

Amorphous indium–zinc oxide

In order to reduce indium content, decrease processing difficulty, and improve electrical homogeneity, amorphous transparent conducting oxides have been developed. One such material, amorphous indium-zinc-oxide maintains short-range order even though

See also

References

- PMID 24117323.

- doi:10.1063/1.371708.

- ^ .

- S2CID 95720073.

- ISBN 978-1-61060-143-6.

- . Retrieved 2025-03-24.

- S2CID 224811369.

- ^ Increasing the Blue Channel Response. Technical Information Bulletin. kodak.com

- ^ Luo, Qing (1 January 2001). Indium tin oxide thin film strain gages for use at elevated temperatures (Thesis). pp. 1–146. Archived from the original on 2 November 2019. Retrieved 2 November 2019.

- S2CID 16369286.

- .

- .

- .

- ^ S2CID 136882786.

- .

- .

- .

- PMID 28787863.

- .

- ^ a b Pern, John (December 2008). "Stability Issues of Transparent Conducting Oxides (TCOs) for Thin-Film Photovoltaics" (PDF). U.S. National Renewable Energy Laboratory.

- ^ ISBN 978-1-4419-1638-9.

- S2CID 5489454.

- ^ National Nanotechnology Initiative. "Energy Conversion and Storage: New Materials and Processes for Energy Needs" (PDF). Archived from the original (PDF) on May 12, 2009.

- ^ "National Nanotechnology Initiative Research and Development Supporting the next Industrial Revolution" (PDF). nano.gov. p. 29.

- PMID 33959732.

- S2CID 122207774.

- ^ POLINARES (EU Policy on Natural Resources, 2012). Fact sheet: Indium. [last accessed 20 Mar 2013]

- PMID 22207675.

- PMID 24164313.

- PMID 14646287.

- PMID 25874458.

- NAID 40021224398.

- ^ "Environment: [Topics2] Development of Materials That Solve Environmental Issues EXCLEAR thin double-sided sensor film for touch panels | FUJIFILM Holdings". www.fujifilmholdings.com.

- PMID 8159952.

- PMID 17050566.

- PMID 10382558.

- PMID 10382557.

- S2CID 53372492.

- ^ Hazardous substance factsheet. New Jersey Department of Health and Senior Services.

- ^ Lenntech Health effects of tin.

- ^ Yokel, R. A. (2014) pp. 116–119 in Encyclopedia of the Neurological Sciences, ed. M. J. Aminoff and R. B. Daroff, Academic Press, Oxford, 2nd ed.

- PMID 34832261.

- PMID 34832261.

- .

- ^ "Researchers find replacement for rare material indium tin oxide" (online). R&D Magazine. Advantage Business Media. 11 April 2011. Retrieved 11 April 2011.

- PMID 21478868.

- ^ ServiceJun. 20, Robert F. (20 June 2010). "Graphene Finally Goes Big". Science. AAAS.

{{cite news}}: CS1 maint: numeric names: authors list (link) - S2CID 97512306.

- S2CID 205244148.

- .

- .

- S2CID 425367.

External links

- Spectroscopic studies of conducting metal oxides, with many slides about ITO