Computer-integrated manufacturing

This article needs additional citations for verification. (March 2010) |

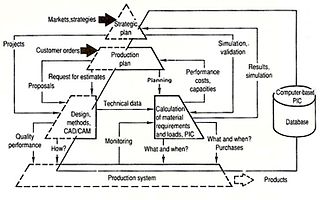

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process.[1][2] This integration allows individual processes to exchange information with each part. Manufacturing can be faster and less error-prone by the integration of computers. Typically CIM relies on closed-loop control processes based on real-time input from sensors. It is also known as flexible design and manufacturing.[3]

Overview

- Computer-integrated manufacturing is used in

- The term "computer-integrated manufacturing" is both a method of manufacturing and the name of a computer-automated system in which individual engineering, production, marketing, and support functions of a manufacturing enterprise are organized.

- In a CIM system functional areas such as materials handlingand management, providing direct control and monitoring of all the operation.

CIM is an example of the implementation of

CIM implies that there are at least two computers exchanging information, e.g. the controller of an arm robot and a micro-controller.

CIM is most useful where a high level of ICT is used in the company or facility, such as CAD/CAM systems, and the availability of process planning and its data.

History

The idea of "digital manufacturing" became prominent in the early 1970s, with the release of Dr. Joseph Harrington's book, Computer Integrated Manufacturing.

- "CIM is the integration of total manufacturing enterprise by using integrated systems and data communication coupled with new managerial philosophies that improve organizational and personnel efficiency." ERHUM

- In a literature research was shown that 37 different concepts of CIM were published, most of them from Germany and USA. In a timeline of the 37 publications it is possible to see how the CIM concept developed over time. Also it is quite markable how different the concepts of all publications are.[6]

Topics

Key challenges

There are three major challenges to development of a smoothly operating computer-integrated manufacturing system:

- Integration of components from different suppliers: When different machines, such as CNC, AGVs, even differing lengths of time for charging the batteries) may cause problems.

- Data integrity: The higher the degree of automation, the more critical is the integrity of the data used to control the machines. While the CIM system saves on labor of operating the machines, it requires extra human labor in ensuring that there are proper safeguards for the data signals that are used to control the machines.

- Process control: Computers may be used to assist the human operators of the manufacturing facility, but there must always be a competent engineer on hand to handle circumstances which could not be foreseen by the designers of the control software.

Subsystems

A computer-integrated manufacturing system is not the same as a "lights-out factory", which would run completely independent of human intervention, although it is a big step in that direction. Part of the system involves flexible manufacturing, where the factory can be quickly modified to produce different products, or where the volume of products can be changed quickly with the aid of computers. Some or all of the following subsystems may be found in a CIM operation:

Computer-aided techniques:

- CAD (computer-aided design)

- CAE (computer-aided engineering)

- CAM (computer-aided manufacturing)

- CAPP (computer-aided process planning)

- CAQ (computer-aided quality assurance)

- PPC (production planning and control)

- ERP (enterprise resource planning)

- A business system integrated by a common database.

Devices and equipment required:

- CNC, Computer numerical controlled machine tools

- DNC, Direct numerical control machine tools

- PLCs, Programmable logic controllers

- Robotics

- Computers

- Software

- Controllers

- Networks

- Interfacing

- Monitoring equipment

Technologies:

- FMS, (flexible manufacturing system)

- ASRS, automated storage and retrieval system

- AGV, automated guided vehicle

- Robotics

- Automated conveyance systems

Others:

CIMOSA

CIMOSA provides a solution for business integration with four types of products:[11]

- The CIMOSA Enterprise Modeling Framework, which provides a reference architecture for enterprise architecture

- CIMOSA IIS, a standard for physical and application integration.

- CIMOSA Systems Life Cycle, is a life cycle model for CIM development and deployment.

- Inputs to standardization, basics for international standard development.

CIMOSA according to Vernadat (1996), coined the term

Areas

There are multiple areas of usage:

- In Industrial and Production engineering

- In mechanical engineering

- In electronic design automation (printed circuit board (PCB) and integrated circuit design data for manufacturing)

See also

- Direct numerical control

- Enterprise integration

- Enterprise resource planning

- Flexible manufacturing system

- Integrated Computer-Aided Manufacturing

- Integrated manufacturing database

- Manufacturing process management

- Product lifecycle management

References

- ISBN 978-7-302-12535-8.

- ISBN 978-0-8493-3086-5.

- ^ "Flexible Manufacturing Systems". 21 March 2017.

- S2CID 23963474.

- ^ http://www.simflow.net/publications/books/cimie-part1.pdf Archived 2020-10-27 at the Wayback Machine [bare URL PDF]

- ^ Meudt, Tobias; Pohl, Malte; Metternich, Joachim (27 July 2017). "Modelle und Strategien zur Einführung des Computer Integrated Manufac-turing (CIM) – Ein Literaturüberblick". TU Prints: 36.

- ISBN 0-471-93450-X.

- AMICE Consortium(1991). Open System Architecture for CIM, Research Report of ESPRIT Project 688, Vol. 1, Springer-Verlag, 1989.

- AMICE Consortium(1991), Open System Architecture, CIMOSA, AD 1.0, Architecture Description, ESPRIT Consortium AMICE, Brussels, Belgium.

- ^ F. Vernadat(1996). Enterprise Modeling and Integration. p.40

- ^ Richard C. Dorf, Andrew Kusiak (1994). Handbook of Design, Manufacturing, and Automation. p.1014

Further reading

- Yoram Koren Computer Control of Manufacturing Systems, McGraw Hill, Inc. 1983, 287 pp, ISBN 0-07-035341-7

- Singh, V (1997). The Cim Debacle: Methodologies to Facilitate Software Interoperability. Springer. ISBN 981-3083-21-2.

- A. de Toni and S. Tonchia, Manufacturing Flexibility: a literature review International Journal of Production Research, 1998, vol. 36, no. 6, 1587–617.

- Jean-Baptiste Waldner (1992), Principles of Computer-Integrated Manufacturing, John Wiley & Sons, ISBN 0-471-93450-X

- Jean-Baptiste Waldner (1990), CIM, les nouvelles perspectives de la production, DUNOD- BORDAS, ISBN 978-2-04-019820-6