Electrospinning

Electrospinning is a fiber production method that uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers.[1] The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product.

Process

When a sufficiently high

As the jet dries in flight, the mode of current flow changes from ohmic to convective as the charge migrates to the surface of the fiber. The jet is then elongated by a whipping process caused by

|

|

Parameters

- Molecular weight, molecular-weight distribution and architecture (branched, linear etc.) of the polymer

- Solution properties (viscosity, conductivity and surface tension)

- Electric potential, flow rate and concentration

- Distance between the capillary and collection screen

- Ambient parameters (temperature, humidity and air velocity in the chamber)

- Motion and size of target screen (collector)

- Needle gauge

| Parameters | Effect on fibers | Linked to |

|---|---|---|

| Solution Parameters | ||

| Viscosity | If too low, no continuous fiber formation will occur; if too high, the ejection of the jet from the needle tip will be impeded. | Polymer concentration, Molecular Weight |

| Polymer Concentration | Increase in concentration results in increased diameter. A minimum concentration is required: if too low, there will not be enough entanglements to sustain the jet (beads). | Surface tension, Viscosity |

| Molecular weight | Reflects the number of entanglements of polymeric chains in solution, thus its viscosity. | Viscosity, Surface tension, Conductivity |

| Conductivity | Directly related to the accumulation of charges under the electric field. Higher conductivity results in stronger stretching of the jet producing smaller diameter fiber. | Voltage |

| Surface tension | With all other parameters fixed, it determines the upper and lower boundaries of the electrospinning window. | |

| Processing Parameters | ||

| Voltage | Fiber formation occurs only after a certain threshold voltage. Higher voltages cause greater stretching of the solution with reduction of fiber diameters; but if the voltage is too high, it may cause instability of the jet and increase the fiber diameter. | Tip to collector distance, Conductivity, Feed rate |

| Tip to collector distance | Affects the traveling time of the polymer jet; should be high enough to allow complete evaporation of the solvent. | Voltage, Feed rate |

| Feed rate | Determines the amount of solution available per unit of time. Influences the jet velocity and the material transfer rate. Increasing the rate causes more polymer to be processed at a given instant, thus increasing fiber diameter. | Tip to collector distance, Voltage, Viscosity |

| Ambient Parameters | ||

| Humidity | High humidity may result in pores on fiber surface | |

| Temperature | An increase in temperature results in a decrease in fiber diameter thanks to a decrease in viscosity. | Viscosity |

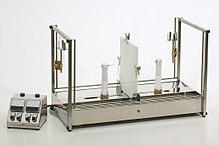

Apparatus and range

The standard laboratory setup for electrospinning consists of a

|

|

Scaling-up possibilities

- Alternating current electrospinning[7][8][9][10][11][12]

- Needleless (also known as, nozzle-free) electrospinning [13][14]

- Multiplying the needles[15]

- High-throughput roller electrospinning[16]

- Wire electrospinning

- Bubble electrospinning[17]

- Ball electrospinning[18][19]

- High speed electrospinning[20]

- Plate edge electrospinning[21]

- Bowl electrospinning[22]

- Hollow tube electrospinning[23]

- Rotary cone electrospinning[24]

- Spiral coil electrospinning[25]

- Electroblowing[26]

Other techniques

Modification of the spinneret and/or the type of solution can allow for the creation of fibers with unique structures and properties. Electrospun fibers can adopt a porous or core–shell morphology depending on the type of materials being spun as well as the evaporation rates and miscibility for the solvents involved. For techniques which involve multiple spinning fluids, the general criteria for the creation of fibers depends upon the spinnability of the outer solution.[27] This opens up the possibility of creating composite fibers which can function as drug delivery systems or possess the ability to self-heal upon failure.[28][29]

Co-axial electrospinning

A coaxial setup uses a dual-solution feed system which allows for the injection of one solution into another at the tip of the spinneret. The sheath fluid is believed to act as a carrier which draws in the inner fluid at the Taylor Cone of the electrospinning jet.[27] If the solutions are immiscible then a core shell structure is usually observed. Miscible solutions however can result in porosity or a fiber with distinct phases due to phase separation during solidification of the fiber. For more advanced setups, a triaxial or quadaxial (tetra-axial) spinneret can be used with multiple solutions.

Emulsion electrospinning

Electrospinning of blends is a variation of this technique which uses the fact that polymers are generally immiscible with each and can phase segregate without the use of surfactants. This method can be simplified further if a solvent which dissolves both polymers is used.[32]

Melt electrospinning

Electrospinning of polymer melts eliminates the need for volatile solvents in solution electrospinning.[33] Semi crystalline polymer fibers such as PE, PET and PP, which would otherwise be impossible or very difficult to create using solution spinning, can be created. The setup is very similar to that employed in conventional electrospinning and includes the use of a syringe or spinneret, a high voltage supply and the collector. The polymer melt is usually produced by heating from either resistance heating, circulating fluids, air heating or lasers.[34]

Due to the high viscosity of polymer melts, the fiber diameters are usually slightly larger than those obtained from solution electrospinning. The fiber uniformity upon achieving stable flow rates and thermal equilibrium, tends to be very good. The whipping instability which is the predominant stage in which the fiber is stretched for spinning from solutions can be absent from the process due to the low melt conductivity and high viscosity of the melt. The most significant factors which affect the fiber size tend to be the feed rate, the molecular weight of the polymer and the diameter of the spinneret. Fiber sizes ranging from ~250 nm to several hundreds of micrometers have been created thus far with the lower sizes being achieved using low molecular weight polymers.[35]

History

In the late 16th century

In 1887 C. V. Boys described “the old, but little known experiment of electrical spinning”. Boys’ apparatus consisted of “a small dish, insulated and connected with an electrical machine”.[37] He found that as his stock liquid reached the edge of the dish, that he could draw fibers from a number of materials including shellac, beeswax, sealing-wax, gutta-percha and collodion.

The process of electrospinning was patented by J.F. Cooley in May 1900[38] and February 1902[39] and by W.J. Morton in July 1902.[40]

In 1914 John Zeleny, published work on the behavior of fluid droplets at the end of metal capillaries.[41] His effort began the attempt to mathematically model the behavior of fluids under electrostatic forces.

Further developments toward commercialization were made by Anton Formhals, and described in a sequence of patents from 1934[42] to 1944[43] for the fabrication of textile yarns. Electrospinning from a melt rather than a solution was patented by C.L. Norton in 1936[44] using an air-blast to assist fiber formation.

In 1938 Nathalie D. Rozenblum and Igor V. Petryanov-Sokolov,

Between 1964 and 1969

Simon, in a 1988 NIH SBIR grant report, showed that solution electrospinning could be used to produce nano- and submicron-scale polystyrene and polycarbonate fibrous mats specifically intended for use as in vitro cell substrates. This early application of electrospun fibrous lattices for cell culture and tissue engineering showed that various cell types would adhere to and proliferate upon the fibers in vitro. Small changes in the surface chemistry of the fibers were also observed depending upon the polarity of the electric field during spinning.[52]

In the early 1990s several research groups (notably that of Reneker and Rutledge who popularised the name electrospinning for the process)[53] demonstrated that many organic polymers could be electrospun into nanofibers. Between 1996 and 2003 the interest in electrospinning underwent an explosive growth, with the number of publications and patent applications approximately doubling every year.[5]

Since 1995 there have been further theoretical developments of the driving mechanisms of the electrospinning process. Reznik et al. described the shape of the Taylor cone and the subsequent ejection of a fluid jet.[54] Hohman et al. investigated the relative growth rates of the numerous proposed instabilities in an electrically forced jet once in flight[55] and endeavors to describe the most important instability to the electrospinning process, the bending (whipping) instability.

Uses

The size of an electrospun fiber can be in the nano scale and the fibers may possess nano scale surface texture, leading to different modes of interaction with other materials compared with macroscale materials.

Filtration

The use of nanofiber webs as a filtering medium is well established. Due to the small size of the fibers London-Van Der Waals forces are an important method of adhesion between the fibers and the captured materials. Polymeric nanofibers have been used in air filtration applications for more than seven decades.[47][57] Because of poor bulk mechanical properties of thin nanowebs, they are laid over a filtration medium substrate. The small fiber diameters cause slip flows at fiber surfaces, causing an increase in the interception and inertial impaction efficiencies of these composite filter media. The enhanced filtration efficiency at the same pressure drop is possible with fibers having diameters less than 0.5 micrometer. Since the essential properties of protective clothing are high moisture vapor transport, increased fabric breath-ability, and enhanced toxic chemical resistance, electrospun nanofiber membranes are good candidates for these applications.[58]

Textile manufacturing

The majority of early patents for electrospinning were for textile applications, however little woven fabric was actually produced, perhaps due to difficulties in handling the barely visible fibers. However, electrospinning has the potential to produce seamless non-woven garments by integrating advanced manufacturing with fiber electrospinning. This would introduce multi-functionality (flame, chemical, environmental protection) by blending fibers into electrospinlaced (using electrospinning to combine different fibers and coatings to form three-dimensional shapes, such as clothing)[59] layers in combination with polymer coatings.[60]

Medical

Electrospinning can also be used for medical purposes.

Cosmetic

Electrospun nanomaterials have been employed to control their delivery so they can work within skin to improve its appearance.[74] Electrospinning is an alternative to traditional nanoemulsions and nanoliposomes.

Pharmaceutical manufacturing

The continuous manner and the effective drying effect enable the integration of electrospinning into continuous pharmaceutical manufacturing systems.[75] The synthesized liquid drug can be quickly turned into an electrospun solid product processable for tableting and other dosage forms.

Composites

Ultra-fine electrospun fibers show clear potential for the manufacture of long fiber composite materials.[76]

Application is limited by difficulties in making sufficient quantities of fiber to make substantial large scale articles in a reasonable time scale. For this reason medical applications requiring relatively small amounts of fiber are a popular area of application for electrospun fiber reinforced materials.

Electrospinning is being investigated as a source of cost-effective, easy to manufacture wound dressings, medical implants, and scaffolds for the production of artificial human tissues. These scaffolds fulfill a similar purpose as the extracellular matrix in natural tissue. Biodegradable polymers, such as polycaprolactone[77] and polysaccharides,[78] are typically used for this purpose. These fibers may then be coated with collagen to promote cell attachment, although collagen has successfully been spun directly into membranes.[79]

|

|

Catalysts

Electrospun fibers may have potential as a surface for enzymes to be immobilized on. These enzymes could be used to break down toxic chemicals in the environment, among other things.[5]

Mass production

Thus far, at least eight countries in the world have companies which provide industrial-level and laboratory-scale electrospinning machines: three companies each in Italy and Czech Republic, two each in Iran, Japan, and Spain, and one each in the Netherlands, New Zealand[80] and Turkey.[81]

References

- ISBN 0-471-98220-2.

- ^ High speed video of the taylor cone formation and electrospinning. youtube.com

- ^ Single nozzle electrospinning process nanofiber formation video. youtube.com

- ^ High speed video of the whipping instability. youtube.com

- ^ S2CID 137659394.

- S2CID 136486578.

- S2CID 245075252.

- PMID 26320549.

- S2CID 224924026.

- S2CID 202207593.

- ISSN 1097-4628.

- S2CID 243969095.

- ^ Niu, Haitao; Lin, Tong (2012). "Fiber generators in needleless electrospinning". Journal of Nanomaterials. 12.

- S2CID 216267121.

- )

- ^ S2CID 235543210.

- .

- S2CID 139814700, retrieved 31 January 2024

- ^ Smit, Eugene; Stegmann, H. (31 January 2024). "Ball-Electrospinning Technology and It's Associated Advantages". [The Stellenbosch Nanofiber Company]. Retrieved 31 January 2024.

- PMID 25596415.

- .

- S2CID 54921.

- .

- PMID 20602427.

- .

- .

- ^ S2CID 36284720.

- PMID 14568403.

- S2CID 97333850.

- PMID 32188479.

- .

- doi:10.1016/j.compscitech.2008.08.033. Archived from the original(PDF) on 3 September 2013. Retrieved 16 May 2013.

- ^ PMID 23161110.

- PMID 21080400.

- doi:10.1016/j.polymer.2007.09.037. Archived from the original(PDF) on 21 December 2009.

- ^ Gilbert, W. (1628) De Magnete, Magneticisque Corporibus, et de Magno Magnete Tellure (On the Magnet and Magnetic Bodies, and on That Great Magnet the Earth), London, Peter Short.

- .

- ^ Cooley, J.F. Patent GB 06385 "Improved methods of and apparatus for electrically separating the relatively volatile liquid component from the component of relatively fixed substances of composite fluids" 19 May 1900

- ^ Cooley, J. F. et al. "Apparatus for electrically dispersing fluids" U.S. patent 692,631 Issue date: February 4, 1902

- ^ Morton, W.J. et al. "Method of dispersing fluids" U.S. patent 0,705,691 Issue date: July 29, 1902

- .

- ^ Formhals, Anton et al. "Process and apparatus for preparing artificial threads" U.S. patent 1,975,504 Issue date: October 2, 1934

- ^ Formhals, Anton et al. "Method and apparatus for spinning" U.S. patent 2,349,950 Issue date: May 30, 1944

- ^ Norton, C.L. "Method and apparatus for producing fibrous or filamentary material" U.S. patent 2,048,651 Issue date: July 21, 1936

- S2CID 188991797.

- ^ Fiber Materials Electrospinning Laboratory (FMEL) Archived 2012-07-12 at the Wayback Machine. electrospinning.ru

- ^ ISBN 978-1-56700-241-6.

- S2CID 15067908.

- S2CID 120946066.

- S2CID 122790146.

- .

- ^ Simon EM (1988). "NIH Phase I Final Report: Fibrous Substrates for Cell Culture (R3RR03544A)". ResearchGate. Retrieved 22 May 2017.

- .

- S2CID 16597181. Archived from the original(PDF) on 27 July 2014. Retrieved 16 May 2013.

- doi:10.1063/1.1383791. Archived from the original(PDF) on 23 July 2008. Retrieved 16 May 2013.

- .

- ^ Donaldson Nanofiber Products Archived 2011-07-10 at the Wayback Machine

- .

- S2CID 136722801.

- ISBN 0-7803-8461-X.

- PMID 18281090.

- S2CID 1047910.

- S2CID 253958743.

- S2CID 252500879.

- PMID 14598393.

- PMID 22609349.

- PMID 20728588.

- PMID 17498935.

- .

- .

- .

- ISBN 978-0-08-102198-9.

- PMID 34201089.

- ^ Zealand BK, Lepe P, Hosie IC (28 June 2018). "A New Spin on Delivery: Electrospun Collagen Drives Actives to New Depths". Cosmetics & Toiletries. New Revolution Fibres Ltd. Retrieved 31 August 2019.

- .

- .

- S2CID 232164709.

- S2CID 237539377.

- PMID 11888306.

- ^ "Revolution Fibres is manufacturing to the sun and back". techweek.co.nz. Archived from the original on 31 August 2019. Retrieved 31 August 2019.

- ^ "Electrospinning Mass Production Machine Providers". electrospintech.com. Retrieved 15 January 2016.

Further reading

- Tucker N, Stanger JJ, Staiger MP, Razzaq H, Hofman K (June 2012). "The history of the science and technology of electrospinning from 1600 to 1995" (PDF). Journal of Engineered Fibers and Fabrics. 7 (2): 63–73. S2CID 53663092.

- Wendorff JH, Agarwal S, Greiner A (2012). Electrospinning : Materials, Processing, and Applications. Hoboken: John Wiley & Sons. ISBN 978-3-527-32080-6.

- Andrady AL (2008). Science and technology of polymer nanofibers. Hoboken, N.J.: John Wiley & Sons. ISBN 978-0-471-79059-4.

- Stanger J, Tucker N, Staiger M (2008). Electrospinning. Shawbury, Shrewsbury, Shropshire: I-Smithers Rapra publishing. ISBN 978-1-84735-091-6.

- Ramakrishna, Fujihara K, Teo WE (2005). An introduction to electrospinning and nanofibers. Singapore: World Scientific. ISBN 981-256-415-2.

- Schubert D (July 2019). "Revealing novel power laws and quantization in electrospinning considering jet splitting—toward predicting fiber diameter and its distribution". Macromolecular Theory and Simulations. 28 (4): 1900006. S2CID 145886940.