Transcritical cycle

| Thermodynamics |

|---|

|

A transcritical cycle is a closed

While in single level supercritical cycles both pressure levels are above the

Transcritical conditions of the working fluid

In transcritical cycles, the pressure of the working fluid at the outlet of the pump is higher than the critical pressure, while the inlet conditions are close to the saturated liquid pressure at the given minimum temperature.

During the heating phase, which is typically considered an

As a consequence, the maximum temperatures reached by the cold source can be higher at fixed hot source characteristics. Therefore, the expansion process can be accomplished exploiting higher pressure ratios, which yields higher power production. Modern ultrasupercritical Rankine cycles can reach maximum temperatures up to 620°C exploiting the optimized heat introduction process.[13]

Characterization of the power cycle

As in any power cycle, the most important indicator of its performance is the thermal efficiency. The thermal efficiency of a transcritical cycle is computed as:

where is the thermal input of the cycle, provided by either combustion or with a heat exchanger, and is the power produced by the cycle.

The power produced is considered comprehensive of the produced power during the expansion process of the working fluid and the one consumed during the compression step.

The typical conceptual configuration of a transcritical cycle employs a single heater,

Characterization of the compression process

Along adiabatic and isentropic processes, such as those theoretically associated with pumping processes in transcritical cycles, the enthalpy difference across both a compression and an expansion is computed as:

Consequently, a working fluid with a lower specific volume (hence higher density) can inevitably be compressed spending a lower mechanical work than one with low density (more gas like).

In transcritical cycles, the very high maximum pressures and the liquid conditions along the whole compression phase ensure a higher density and a lower specific volume with respect to supercritical counterparts. Considering the different physical phases though which compression processes occur, transcritical and supercritical cycles employ pumps (for liquids) and compressors (for gases), respectively, during the compression step.

Characterization of the expansion process

In the expansion step of the working fluid in transcritical cycles, as in subcritical ones, the working fluid can be discharged either in wet or dry conditions.

Typical dry expansions are those involving organic or other unconventional working fluids, which are characterized by non-negligible molecular complexities and high molecular weights.

The expansion step occurs in turbines: depending on the application and on the nameplate power produced by the power plant, both axial turbines and radial turbines can be exploited during fluid expansion. Axial turbines favour lower rotational speed and higher power production, while radial turbines are suitable for limited powers produced and high rotational speed.

Organic cycles are appropriate choices for low enthalpy applications and are characterized by higher average densities across the expanders than those occurring in transcritical steam cycles: for this reason a low blade height is normally designed [18] and the volumetric flow rate is kept limited to relatively small values. On the other hand in large scale application scenarios the expander blades typically show heights that exceed one meter and that are exploited in the steam cycles. Here, in fact, the fluid density at the outlet of the last expansion stage is significantly low.

In general, the specific work of the cycle is expressed as:

Even though the specific work of any cycle is strongly dependent on the actual working fluid considered in the cycle, transcritical cycles are expected to exhibit higher specific works than the corresponding subcritical and supercritical counterparts (i.e., that exploit the same working fluid). For this reason, at fixed boundary conditions, power produced and working fluid, a lower mass flow rate is expected in transcritical cycles than in other configurations.

Applications in power cycles

Ultrasupercritical Rankine cycles

In the last decades, the thermal efficiency of Rankine cycles increased drastically, especially for large scale applications fueled by coal: for these power plants, the application of ultrasupercritical layouts was the main factor to achieve the goal, since the higher pressure ratio ensures higher cycle efficiencies.

The increment in thermal efficiency of power plants fueled by dirty fuels became crucial also in the reduction of the specific emissions of the plants, both in therms of greenhouse gas and for pollutant such as sulfur dioxide or NOx. In large scale applications, ultrasupercritical Rankine cycles employ up to 10 feedwater heaters, five on the high pressure side and five on the low pressure side, including the deaerator, helping in the increment of the temperature at the inlet of the boiler up to 300°C, allowing a significant regenerative air preheating, thus reducing the fuel consumption. Studies on the best performant configurations of supercritical rankine cycles (300 bar of maximum pressure, 600°C of maximum temperature and two reheats) show that such layouts can achieve a cycle efficiency higher than 50%, about 6% higher than subcritical configurations.[19]

Organic Rankine cycles

Organic Rankine cycles are innovative power cycles which allow good performances for low enthalpy thermal sources[20] and ensure condensation above the atmospheric pressure, thus avoiding deaerators and large cross sectional area in the heat rejection units. Moreover, with respect to steam Rankine cycles, ORC have a higher flexibility in handling low power sizes, allowing significant compactness. Typical applications of ORC cover: waste heat recovery plants, geothermal plants, biomass plants and waste to energy power plants.

Organic Rankine cycles use organic fluids (such as

Applications in refrigeration cycles

A refrigeration cycle, also known as heat pump, is a thermodynamic cycle that allows the removal of heat from a low temperature heat source and the rejection of heat into a high temperature heat source, thanks to mechanical power consumption.[24] Traditional refrigeration cycles are subcritical, with the high pressure side (where heat rejection occurs) below the critical pressure.[25]

Innovative transcritical refrigeration cycles, instead, should use a working fluid whose

In transcritical refrigeration cycles the heat is dissipated through a gas cooler instead of a desuperheater and a condenser[26] like in subcritical cycles. This limits the plant components, plant complexity and costs of the power block.

The advantages of using supercritical carbon dioxide as working fluid, instead of traditional refrigerant fluids (like HFC of HFO), in refrigeration cycles is represented both by economic aspects and environmental ones. The cost of carbon dioxide is two order of magnitude lower than the ones of the average refrigerant working fluid and the environmental impact of carbon dioxide is very limited (with a GWP of 1 and an ODP of 0), the fluid is not reactive nor significantly toxic. No other working fluids for refrigeration is able to reach the same environmental favourable characteristics of carbon dioxide.[27]

-

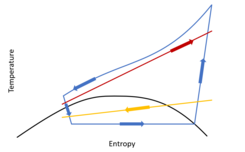

Ts diagram of a transcritical heat pump: cold source (yellow), hot source (red), transcritical cycle (blue)

-

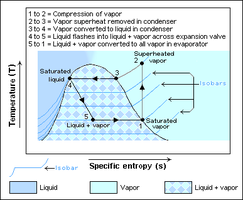

A subcritical refrigeration cycle, where heat rejection occurs at a pressure lower than the critical one

References

- ISBN 978-0-08-100314-5.

- .

- S2CID 218783771.

- hdl:1854/LU-8622604.

- S2CID 115970056.

- hdl:10044/1/44744.

- .

- .

- PMID 32982085.

- .

- .

- ISBN 978-0-08-100510-1.

- )

- S2CID 115603205.

- .

- .

- .

- .

- .

- S2CID 210612763.

- .

- .

- ^ Bombarda, Paola. Comparison of Enhanced Organic Rankine Cycles for Geothermal Power Units (PDF). [Melbourne].

- ISBN 978-3-662-49088-4.

- S2CID 234824823.

- ^ Sarkar, Jahar (2010). "Review on Cycle Modifications of Transcritical CO2 Refrigeration and Heat Pump Systems". Journal of Advanced Research in Mechanical Engineering. 1 (1): 22–29.

- .