Aerogel

aerogel: gel comprised of a microporous solid in which the dispersed phase is a gas. (See Gold Book entry for note.) [1]

Aerogels are a class of

Aerogels are produced by extracting the liquid component of a gel through

History

The first documented example of an aerogel was created by

Properties

An aerogel material can range from 50% to 99.98% air by volume, but in practice most aerogels exhibit somewhere between 90 and 99.8% porosity.[10] Aerogels have a porous solid network that contains air pockets, with the air pockets taking up the majority of space within the material.[11]

Aerogels are good

Owing to its

The slight colour it does have is due to

Aerogels by themselves are

Structure

Aerogel structure results from a

Porosity of aerogel

There are several ways to determine the porosity of aerogel: the three main methods are gas

Knudsen effect

Aerogels may have a

Waterproofing

Aerogel contains particles that are 2–5 nm in diameter. After the process of creating aerogel, it will contain a large amount of

Production

Overview

The preparation of silica aerogels typically involves three distinct steps:[19] the sol-gel transition (gelation),[20] the network perfection (aging), and[21] the gel-aerogel transition (drying).

Gelation

Silica aerogels are typically synthesized by using a sol-gel process. The first step of the sol-gel process is the creation of a

For some materials, the transition from a colloidal dispersion into a gel happens without the addition of crosslinking materials.[25] For others, crosslinking materials are added to the dispersion to promote the strong interaction of the solid particles in order to form the gel.[26][27] The gelation time depends heavily on a variety of factors such as the chemical composition of the precursor solution, the concentration of the precursor materials and additives, the processing temperature, and the pH.[28][29][30][31][32] Many materials may require additional curing after gelation (i.e., network perfection) in order to strengthen the aerogel network.[33][34][35][36][37][38]

Drying

Once the gelation is completed, the liquid surrounding the silica network is carefully removed and replaced with air, while keeping the aerogel intact. It is crucial that the gel is dried in such a way as to minimize the surface tension within the pores of the solid network. This is typically accomplished through supercritical fluid extraction using supercritical carbon dioxide (scCO2) or freeze-drying.This section briefly describes and compares the processing strategies of supercritical drying and freeze-drying.

Gels where the liquid is allowed to evaporate at a natural rate are known as

In 1931, to develop the first aerogels, Kistler used a process known as supercritical drying which avoids a direct phase change.[41] By increasing the temperature and pressure he forced the liquid into a supercritical fluid state where by dropping the pressure he could instantly gasify and remove the liquid inside the aerogel, avoiding damage to the delicate three-dimensional network. While this can be done with ethanol, the high temperatures and pressures lead to dangerous processing conditions. A safer, lower temperature and pressure method involves a solvent exchange. This is typically done by exchanging the initial aqueous pore liquid for a CO2-miscible liquid such as ethanol or acetone, then onto liquid carbon dioxide, and then bringing the carbon dioxide above its critical point.[42] A variant on this process involves the direct injection of supercritical carbon dioxide into the pressure vessel containing the aerogel. The result of either process exchanges the initial liquid from the gel with carbon dioxide, without allowing the gel structure to collapse or lose volume.[23]

Supercritical Drying

To dry the gel, while preserving the highly porous network of an aerogel, supercritical drying employs the use of the liquid-gas transition that occurs beyond the critical point of a substance. By using this liquid-gas transition that avoids crossing the liquid-gas phase boundary, the surface tension that would arise within the pores due to the evaporation of a liquid is eliminated, thereby preventing the collapse of the pores.[43] Through heating and pressurization, the liquid solvent reaches its critical point, at which point the liquid and gas phases become indistinguishable. Past this point, the supercritical fluid is converted into the gaseous phase upon an isothermal de-pressurization. This process results in a phase change without crossing the liquid-gas phase boundary. This method is proven to be excellent at preserving the highly porous nature of the solid network without significant shrinkage or cracking. While other fluids have been reported for the creation of supercritically dried aerogels, scCO2 is the most common substance with a relatively mild supercritical point at 31 °C and 7.4 MPa. CO2 is also relatively non-toxic, non-flammable, inert, and cost-effective when compared to other fluids, such as methanol or ethanol.[44] While being a highly effective method for producing aerogels, supercritical drying takes several days, requires specialized equipment, and presents significant safety hazards due to its high-pressure operation.

Freeze-Drying

Freeze-drying, also known as freeze-casting or ice-templating, offers an alternative to the high temperature and high-pressure requirements of supercritical drying. Additionally, freeze-drying offers more control of the solid structure development by controlling the ice crystal growth during freezing.[45][46][47][48] In this method, a colloidal dispersion of the aerogel precursors is frozen, with the liquid component freezing into different morphologies depending on a variety of factors such as the precursor concentration, type of liquid, temperature of freezing, and freezing container.[49][50][51] As this liquid freezes, the solid precursor molecules are forced into the spaces between the growing crystals. Once completely frozen, the frozen liquid is sublimed into a gas through lyophilization, which removes much of the capillary forces, as was observed in supercritical drying.[52][53] Though typically classified as a “cryogel”, aerogels produced through freeze-drying often experience some shrinkage and cracking while also producing a non-homogenous aerogel framework.[54] This often leads to freeze-drying being used for the creation of aerogel powders or as a framework for composite aerogels.[55][56][57][58][59]

Preparation of non-silica aerogels

Resorcinol–formaldehyde aerogel (RF aerogel) is made in a way similar to production of silica aerogel. A carbon aerogel can then be made from this resorcinol–formaldehyde aerogel by pyrolysis in an inert gas atmosphere, leaving a matrix of carbon.[60] The resulting carbon aerogel may be used to produce solid shapes, powders, or composite paper.[61] Additives have been successful in enhancing certain properties of the aerogel for the use of specific applications. Aerogel composites have been made using a variety of continuous and discontinuous reinforcements. The high aspect ratio of fibers such as fiberglass have been used to reinforce aerogel composites with significantly improved mechanical properties.

Materials

Silica aerogel

Silica aerogels are the most common type of aerogel, and the primary type in use or study.

The silica solidifies into three-dimensional, intertwined clusters that make up only 3% of the volume. Conduction through the solid is therefore very low. The remaining 97% of the volume is composed of air in extremely small nanopores. The air has little room to move, inhibiting both convection and gas-phase conduction.[67]

Silica aerogel also has a high optical transmission of ~99% and a low refractive index of ~1.05.[68] It is very robust with respect to high power input beam in continuous wave regime and does not show any boiling or melting phenomena.[69] This property permits to study high intensity nonlinear waves in the presence of disorder in regimes typically unaccessible by liquid materials, making it promising material for nonlinear optics.

This aerogel has remarkable thermal insulative properties, having an extremely low

Until 2011, silica aerogel held 15 entries in Guinness World Records for material properties, including best insulator and lowest-density solid, though it was ousted from the latter title by the even lighter materials aerographite in 2012[72] and then aerographene in 2013.[73][74]

Carbon

The term "aerogel" to describe airy masses of carbon nanotubes produced through certain chemical vapor deposition techniques is incorrect. Such materials can be spun into fibers with strength greater than Kevlar, and unique electrical properties. These materials are not aerogels, however, since they do not have a monolithic internal structure and do not have the regular pore structure characteristic of aerogels.

Metal oxide

Aerogels made with

One of the most notable differences between silica aerogels and metal oxide aerogel is that metal oxide aerogels are often variedly colored.[75]

| Aerogel | Color |

|---|---|

zirconia |

Clear with Rayleigh scattering blue or white |

| Iron oxide | Rust red or yellow, opaque |

| Chromia | Deep green or deep blue, opaque |

Vanadia |

Olive green, opaque |

Neodymium oxide |

Purple, transparent |

| Samaria | Yellow, transparent |

| Holmia, erbia | Pink, transparent |

Other

Organic polymers can be used to create aerogels. SEAgel is made of agar. AeroZero film is made of polyimide. Cellulose from plants can be used to create a flexible aerogel.[76]

GraPhage13 is the first graphene-based aerogel assembled using

Chalcogel is an aerogel made of chalcogens (the column of elements on the periodic table beginning with oxygen) such as sulfur, selenium, and other elements.[78] Metals less expensive than platinum have been used in its creation.

Aerogels made of

Aerogel performance may be augmented for a specific application by the addition of dopants, reinforcing structures, and hybridizing compounds. For example, Spaceloft is a composite of aerogel with some kind of fibrous batting.[80]

Applications

-

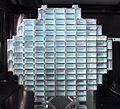

The "Stardust" dust collector with aerogel blocks. (NASA)

-

Cosmic dust caught in aerogel blocks from "Stardust". (NASA)

-

Oil absorption by an aerogel.[81] (Scientific Reports)

-

An aerogel held up by hair.[81] (Scientific Reports)

-

An aerogel holding crayons, with a flame lit underneath, demonstrating its excellent insulation from heat. (NASA)

Aerogels are used for a variety of applications:

- Georgia Institute of Technology's 2007 Solar Decathlon House project used an aerogel as an insulator in the semi-transparent roof.[84]

- A chemical adsorber for cleaning up spills.[85] Silica aerogels may be used for filtration; They have a high surface area, porosity, and are ultrahydrophobic. They may be used for the removal of heavy metals. This could be applied to wastewater treatment.[86]

- As a solar radiation and thermal emittance. Aerogels may be lower in cost and negative environmental impacts than other materials.[87][88]

- A

- Silica aerogels can be used in imaging devices, optics, and light guides.[68]

- Thickening agents in some paints and cosmetics.[90][68][91]

- As components in energy absorbers.[92]

- Laser targets for the United States National Ignition Facility (NIF).[93]

- A material used in impedance matchers for transducers, speakers and range finders.[94]

- According to Journal of Nanomaterials, aerogels are used for more flexible materials such as clothing and blankets: "Commercial manufacture of aerogel 'blankets' began around the year 2000, combining silica aerogel and fibrous reinforcement that turns the brittle aerogel into a durable, flexible material. The mechanical and thermal properties of the product may be varied based upon the choice of reinforcing fibers, the aerogel matrix and opacification additives included in the composite."[68]

- Silica aerogel has been used to capture cosmic dust, also known as space dust.[95][96] NASA used an aerogel to trap space dust particles aboard the Stardust spacecraft.[97] These aerogel dust collectors have very low mass.[98] The particles vaporize on impact with solids and pass through gases, but can be trapped in aerogels. NASA also used aerogel for thermal insulation for the Mars rovers.[99][100][68]

- The US Navy evaluated use of aerogels in undergarments as passive thermal protection for divers.[101][68] Similarly, aerogels have been used by NASA for insulating space suits.[102][68]

- In cryogenic liquids or compressed gases.[104]

- Resorcinol–formaldehyde aerogels (polymers chemically similar to phenol formaldehyde resins) are used as precursors for manufacture of carbon aerogels, or when an organic insulator with large surface is desired.[105]

- Metal–aerogel nanocomposites prepared by impregnating the hydrogel with solution containing ions of a transition metal and irradiating the result with gamma rays, precipitates nanoparticles of the metal. Such composites can be used as catalysts, sensors, and electromagnetic shielding, and in waste disposal. A prospective use of platinum-on-carbon catalysts is in fuel cells.[106]

- As a drug delivery system owing to its biocompatibility. Due to its high surface area and porous structure, drugs can be adsorbed from supercritical CO

2. The release rate of the drugs can be tailored by varying the properties of the aerogel.[107] - Carbon aerogels are used in the construction of small electrochemical double layer

- Dunlop Sport uses aerogel in some of its racquets for sports such as tennis.[109]

- In water purification, chalcogels have shown promise in absorbing the heavy metal pollutants mercury, lead, and cadmium from water.[110] Aerogels may be used to separate oil from water, which could for example be used to respond to oil spills.[111][86][81] Aerogels may be used to disinfect water, killing bacteria.[112][113]

- Aerogel can introduce disorder into

- In aircraft de-icing, a new proposal uses a carbon nanotube aerogel. A thin filament is spun on a winder to create a 10 micron-thick film. The amount of material needed to cover the wings of a jumbo jet weighs 80 grams (2.8 oz). Aerogel heaters could be left on continuously at low power, to prevent ice from forming.[115]

- Thermal insulation transmission tunnel of the Chevrolet Corvette (C7).[116]

- CamelBak uses aerogel as insulation in a thermal sport bottle.[117]

- 45 North uses aerogel as palm insulation in its Sturmfist 5 cycling gloves.[118]

- Silica aerogels may be used for sound insulation, such as on windows or for construction purposes.[119][120]

- It has been suggested that Fogbank, a material of secret composition used in U.S. thermonuclear warheads, may be an aerogel.[121]

Safety

Silica-based aerogels are not known to be

See also

References

![]() This article incorporates text by Elizabeth Barrios, David Fox, Yuen Yee Li Sip, Ruginn Catarata, Jean E. Calderon, Nilab Azim, Sajia Afrin, Zeyang Zhang and Lei Zhai available under the CC BY 4.0 license.

This article incorporates text by Elizabeth Barrios, David Fox, Yuen Yee Li Sip, Ruginn Catarata, Jean E. Calderon, Nilab Azim, Sajia Afrin, Zeyang Zhang and Lei Zhai available under the CC BY 4.0 license.

- . Retrieved 1 April 2024.

- ISBN 978-0-9678550-9-7. Archivedfrom the original on 30 November 2012.

- ^ "Guinness Records Names JPL's Aerogel World's Lightest Solid". NASA. Jet Propulsion Laboratory. 7 May 2002. Archived from the original on 25 May 2009. Retrieved 25 May 2009.

- ISBN 978-1-4419-7477-8.

- S2CID 91183262.

- ^ ISSN 0166-9834.

- ISBN 9781482227451. Archivedfrom the original on 22 November 2017.

- S2CID 4077344.

- .

- ^ "What is Aerogel?". Aerogel.org. Retrieved 22 January 2023.

- ^ "What is Aerogel? Theory, Properties and Applications". azom.com. 12 December 2013. Archived from the original on 9 December 2014. Retrieved 5 December 2014.

- ^ Aerogel Structure Archived 25 December 2014 at the Wayback Machine. Str.llnl.gov. Retrieved on 31 July 2016.

- ^ "Silica Aerogel". Aerogel.org. Archived from the original on 4 April 2016.

- ^ Pore Structure of Silica Aerogels Archived 1 December 2014 at the Wayback Machine. Energy.lbl.gov. Retrieved on 31 July 2016.

- PMID 30200271.

- ISBN 978-0-387-88953-5, retrieved 29 March 2021

- ^ Berge, Axel and Johansson, Pär (2012) Literature Review of High Performance Thermal Insulation Archived 21 November 2014 at the Wayback Machine. Department of Civil and Environmental Engineering, Chalmers University of Technology, Sweden

- ^ The Surface Chemistry of Silica Aerogels Archived 1 December 2014 at the Wayback Machine. Energy.lbl.gov. Retrieved on 31 July 2016.

- ^ Araby, S.; Qiu, A.; Wang, R.; Zhao, Z.; Wang, C.H.; Ma, J. Aerogels based on carbon nanomaterials. J. Mater. Sci. 2016, 51, 9157–9189.

- ^ Pierre, A.C. History of Aerogels. In Aerogels Handbook. Advances in Sol-Gel Derived Materials and Technologies; Aegerter, M., Leventis, N., Koebel, M., Eds.; Springer: New York, NY, USA, 2011; pp. 3–18.

- ^ Zhang, M.; Fang, S.; Zakhidov, A.A.; Lee, S.B.; Alieve, A.E.; Williams, C.D.; Atkinson, K.R.; Baughman, R.H. Strong, transparent, multifunctinoal, carbon nanotube sheets. Science 2005, 209, 1215–1220.

- .

- ^ a b c "Making silica aerogels". Lawrence Berkeley National Laboratory. Archived from the original on 14 May 2009. Retrieved 28 May 2009.

- PMID 12428989.

- ^ Hüsing, N.; Schubert, U. Aerogels—Airy Materials: Chemistry, Structure, and Properties. Angew. Chem. Int. Ed. 1998, 37, 22–45.

- ^ Capadona, L.A.; Meador, M.A.B.; Alunni, A.; Fabrizio, E.F.; Vassilaras, P.; Leventis, N. Flexible, low-density polymer crosslinked silica aerogels. Polymer 2006, 47, 5754–5761.

- ^ Leventis, N.; Lu, H. Polymer-Crosslinked Aerogels. In Aerogels Handbook. Advances in Sol-Gel Derived Materials and Technologies; Aegerter, M., Leventis, N., Koebel, M., Eds.; Springer: New York, NY, USA, 2011; pp. 251–285.

- ^ Capadona, L.A.; Meador, M.A.B.; Alunni, A.; Fabrizio, E.F.; Vassilaras, P.; Leventis, N. Flexible, low-density polymer crosslinked silica aerogels. Polymer 2006, 47, 5754–5761.

- ^ Hench, L.L.; West, J.K. The sol-gel process. Chem. Rev. 1990, 90, 33–72.

- ^ Mulik, S.; Sotiriou-leventis, C.; Leventis, N. Time-Efficient Acid-Catalyzed Synthesis of Resorcinol—Formaldehyde Aerogels. Chem. Mater. 2007, 19, 6138–6144.

- ^ Zhang, J.; Cao, Y.; Feng, J.; Wu, P. Graphene-oxide-sheet-induced gelation of cellulose and promoted mechanical properties of composite aerogels. J. Phys. Chem. C 2012, 116, 8063–8068.

- ^ Hdach, H.; Woignier, T.; Phalippou, J.; Scherer, G.W. Effect of aging and pH on the modulus of aerogels. J. Non-Cryst. Solids 1990, 121, 202–205.

- ^ Capadona, L.A.; Meador, M.A.B.; Alunni, A.; Fabrizio, E.F.; Vassilaras, P.; Leventis, N. Flexible, low-density polymer crosslinked silica aerogels. Polymer 2006, 47, 5754–5761.

- ^ Einarsrud, M.; Nilsen, E.; Rigacci, A.; Pajonk, G.M.; Buathier, S. Strengthening of silica gels and aerogels by washing and aging processes. J. Non-Cryst. Solids 2001, 285, 1–7.

- ^ Soleimani Dorcheh, A.; Abbasi, M.H. Silica aerogel; synthesis, properties and characterization. J. Mater. Process. Technol. 2008, 199, 10–26.

- ^ Hæreid, S.; Anderson, J.; Einarsrud, M.A.; Hua, D.W.; Smith, D.M. Thermal and temporal aging of TMOS-based aerogel precursors in water. J. Non-Cryst. Solids 1995, 185, 221–226.

- ^ Omranpour, H.; Motahari, S. Effects of processing conditions on silica aerogel during aging: Role of solvent, time and temperature. J. Non-Cryst. Solids 2013, 379, 7–11.

- ^ Cheng, C.-P.; Iacobucci, P.A. Inorganic Oxide Aerogels and Their Preparation. U.S. Patent 4,717,708, 5 January 1988.

- .

- S2CID 18169604.

- ^ ISSN 0103-5053.

- ISSN 0167-577X.

- ^ Gurav, J.L.; Jung, I.K.; Park, H.H.; Kang, E.S.; Nadargi, D.Y. Silica aerogel: Synthesis and applications. J. Nanomater. 2010, 2010, 23.

- ^ Beckman, E.J. Supercritical or near-critical CO2 in green chemical synthesis and processing. J. Supercrit. Fluids 2004, 28, 121–191.

- ^ Jin, H.; Nishiyama, Y.; Wada, M.; Kuga, S. Nanofibrillar cellulose aerogels. Colloids Surfaces A Physicochem. Eng. Asp. 2004, 240, 63–67.

- ^ Jiménez-Saelices, C.; Seantier, B.; Cathala, B.; Grohens, Y. Effect of freeze-drying parameters on the microstructure and thermal insulating properties of nanofibrillated cellulose aerogels. J. Sol-Gel Sci. Technol. 2017, 84, 475–485.

- ^ Wang, C.; Chen, X.; Wang, B.; Huang, M.; Wang, B.; Jiang, Y.; Ruoff, R.S. Freeze-Casting Produces a Graphene Oxide Aerogel with a Radial and Centrosymmetric Structure. ACS Nano 2018, 12, 5816–5825.

- ^ Simon-Herrero, C.; Caminero-Huertas, S.; Romero, A.; Valverde, J.L.; Sanchez-Silva, L. Effects of freeze-drying conditions on aerogel properties. J. Mater. Sci. 2016, 51, 8977–8985.

- ^ Jiménez-Saelices, C.; Seantier, B.; Cathala, B.; Grohens, Y. Effect of freeze-drying parameters on the microstructure and thermal insulating properties of nanofibrillated cellulose aerogels. J. Sol-Gel Sci. Technol. 2017, 84, 475–485.

- ^ Wang, C.; Chen, X.; Wang, B.; Huang, M.; Wang, B.; Jiang, Y.; Ruoff, R.S. Freeze-Casting Produces a Graphene Oxide Aerogel with a Radial and Centrosymmetric Structure. ACS Nano 2018, 12, 5816–5825.

- ^ Simon-Herrero, C.; Caminero-Huertas, S.; Romero, A.; Valverde, J.L.; Sanchez-Silva, L. Effects of freeze-drying conditions on aerogel properties. J. Mater. Sci. 2016, 51, 8977–8985.

- ^ Deville, S. Ice-templating, freeze casting: Beyond materials processing. J. Mater. Res. 2013, 28, 2202–2219.

- ^ Deville, S. The lure of ice-templating: Recent trends and opportunities for porous materials. Scr. Mater. 2018, 147, 119–124.

- ^ Gurav, J.L.; Jung, I.K.; Park, H.H.; Kang, E.S.; Nadargi, D.Y. Silica aerogel: Synthesis and applications. J. Nanomater. 2010, 2010, 23.

- ^ Shen, C.; Calderon, J.E.; Barrios, E.; Soliman, M.; Khater, A.; Jeyaranjan, A.; Tetard, L.; Gordon, A.; Seal, S.; Zhai, L. Anisotropic electrical conductivity in polymer derived ceramics induced by graphene aerogels. J. Mater. Chem. C 2017, 5, 11708–11716.

- ^ Ali, I.; Chen, L.; Huang, Y.; Song, L.; Lu, X.; Liu, B.; Zhang, L.; Zhang, J.; Hou, L.; Chen, T. Humidity-Responsive Gold Aerogel for Real-Time Monitoring of Human Breath. Langmuir 2018, 34, 4908–4913.

- ^ Cong, L.; Li, X.; Ma, L.; Peng, Z.; Yang, C.; Han, P.; Wang, G.; Li, H.; Song, W.; Song, G. High-performance graphene oxide/carbon nanotubes aerogel-polystyrene composites: Preparation and mechanical properties. Mater. Lett. 2018, 214, 190–193.

- ^ Cao, N.; Lyu, Q.; Li, J.; Wang, Y.; Yang, B.; Szunerits, S.; Boukherroub, R. Facile synthesis of fluorinated polydopamine/chitosan/reduced graphene oxide composite aerogel for efficient oil/water separation. Chem. Eng. J. 2017, 326, 17–28.

- ^ Jia, J.; Wang, C. A facile restructuring of 3D high water absorption aerogels from methoxy polyethylene glycol-polycaprolactone (mPEG-PCL) nanofibers. Mater. Sci. Eng. C 2019, 94, 965–975.

- .

- ^ "Carbon Aerogel - an overview | ScienceDirect Topics". ScienceDirect. Retrieved 29 March 2021.

- ^ "Aerogels: Thinner, Lighter, Stronger". NASA. 15 April 2015. Retrieved 29 March 2021.

- ^ Taher, Abul (19 August 2007). "Scientists hail 'frozen smoke' as material that will change world". Times Online. London. Archived from the original on 12 September 2007. Retrieved 22 August 2007.

- ^ a b Aerogels Terms. LLNL.gov

- ^ "Lab's aerogel sets world record". LLNL Science & Technology Review. October 2003. Archived from the original on 9 October 2006.

- ^ Groom, D.E. Abridged from Atomic Nuclear Properties Archived 27 February 2008 at the Wayback Machine. Particle Data Group: 2007.

- ^ "About Aerogel". Aspen Aerogels. ASPEN AEROGELS, INC. Archived from the original on 26 May 2014. Retrieved 12 March 2014.

- ^ .

- PMID 24515173.

- ISBN 0-8493-0486-5. Section 12, p. 227

- S2CID 55430528.

- S2CID 2787227.

- ^ Whitwam, Ryan (26 March 2013). Graphene aerogel is world's lightest material Archived 27 March 2013 at the Wayback Machine. gizmag.com

- ^ Quick, Darren (24 March 2013). Graphene aerogel takes world's lightest material crown Archived 25 March 2013 at the Wayback Machine. gizmag.com

- ^ "Metal Oxide Aerogels". Aerogel.org. Archived from the original on 12 August 2013. Retrieved 12 June 2013.

- PMID 24985785.

- Lay summary in: Manisha Lalloo (10 July 2014). "Plant material aligns to make tough aerogels". ChemistryWorld. Royal Society of Chemistry.

- ^ Passaretti, P., et al. (2019). "Multifunctional graphene oxide-bacteriophage based porous three-dimensional micro-nanocomposites." Nanoscale 11(28): 13318-13329. https://doi.org/10.1039/C9NR03670A

- ^ Biello, David Heavy Metal Filter Made Largely from Air. Archived 26 February 2015 at the Wayback Machine Scientific American, 26 July 2007. Retrieved on 2007-08-05.

- PMID 18335987.

- ^ "Strong and Flexible Aerogels". Aerogel.org. Archived from the original on 11 October 2014. Retrieved 17 July 2014.

- ^ PMID 25976019.

- S2CID 209375441.

- S2CID 239117650.

- ^ Solar Decathon 2007. GATech.edu

- S2CID 191132567.

- ^ .

- S2CID 252076428– via Wiley.

- S2CID 252678873– via Elsevier Science Direct.

- S2CID 97092432.

- ^ Spoon, Marianne English (25 February 2014). "'Greener' aerogel technology holds potential for oil and chemical clean-up". University of Wisconsin Madison News. Archived from the original on 28 April 2015. Retrieved 29 April 2015.

- ^ "Taking control". Cosmetics Business. 1 April 2006. Archived from the original on 6 November 2020. Retrieved 29 March 2021.

- S2CID 105477931.

- PMID 29946021.

- .

- PMID 29710971.

- ISSN 0022-3093.

- ^ "NASA - Catching Comet Dust With Aerogel". NASA. Retrieved 29 March 2021.

- ^ Tsou, Peter. "Silica Aerogel Captures Cosmic Dust Intact" (PDF). NASA. Retrieved 29 March 2021.

- ^ Preventing heat escape through insulation called "aerogel" Archived 13 October 2007 at the Wayback Machine, NASA CPL

- ^ Down-to-Earth Uses for Space Materials Archived 30 September 2007 at the Wayback Machine, The Aerospace Corporation

- ^ Nuckols, M. L.; Chao J. C.; Swiergosz M. J. (2005). "Manned Evaluation of a Prototype Composite Cold Water Diving Garment Using Liquids and Superinsulation Aerogel Materials". United States Navy Experimental Diving Unit Technical Report. NEDU-05-02. Archived from the original on 20 August 2008. Retrieved 21 April 2008.

{{cite journal}}: CS1 maint: unfit URL (link) - .

- ISSN 2050-3911.

- PMID 36133881.

- ISBN 978-1-4419-7589-8, retrieved 29 March 2021

- PMC 9640595.

- .

- ^ Juzkow, Marc (1 February 2002). "Aerogel Capacitors Support Pulse, Hold-Up, and Main Power Applications". Power Electronic Technology. Archived from the original on 15 May 2007.

- ^ "Dunlop Expands Aerogel Line - Tennis Industry". Tennis Industry Magazine. July 2007. Retrieved 29 March 2021.

- ^ Carmichael, Mary. First Prize for Weird: A bizarre substance, like 'frozen smoke,' may clean up rivers, run cell phones and power spaceships. Archived 17 August 2007 at the Wayback Machine Newsweek International, 13 August 2007. Retrieved on 2007-08-05.

- S2CID 155307402.

- S2CID 220474580.

- ^ Patel, Prachi (21 August 2020). "Loofah-inspired aerogel efficiently filters microbes from water". Chemical & Engineering News. Retrieved 29 March 2021.

- ^ Halperin, W. P. and Sauls, J. A. Helium-Three in Aerogel. Arxiv.org (26 August 2004). Retrieved on 7 November 2011.

- ^ "De-icing aeroplanes: Sooty skies". The Economist. 26 July 2013. Archived from the original on 30 December 2013. Retrieved 11 December 2013.

- ^ Katakis, Manoli. (11 July 2013) NASA Aerogel Material Present In 2014 Corvette Stingray Archived 22 February 2014 at the Wayback Machine. GM Authority. Retrieved on 2016-07-31.

- ^ Camelbak Podium Ice Insulated Bottle – Review Archived 3 October 2014 at the Wayback Machine. Pinkbike. Retrieved on 31 July 2016.

- ^ Unparalleled Cold Weather Performance Archived 10 January 2016 at the Wayback Machine. 45NRTH. Retrieved on 31 July 2016.

- ^ "Silica Aerogels - an overview". ScienceDirect. Retrieved 29 March 2021.

- S2CID 233562867.

- ^ Last, Jonathan V. (18 May 2009). "The Fog of War: Forgetting what we once knew". The Weekly Standard. Vol. 14, no. 33. Archived from the original on 5 December 2018.

- .

- ^ Cryogel 5201, 10201 Safety Data Sheet Archived 23 December 2010 at the Wayback Machine. Aspen Aerogels. 13 November 2007

- Further reading

External links

- Open-source aerogel

- Aerogel Research at LBL: From the Lab to the Marketplace, Jeffery Kahn, Summer 1991, Berkeley Lab (Lawrence Berkeley National Laboratory)

![Oil absorption by an aerogel.[81] (Scientific Reports)](http://upload.wikimedia.org/wikipedia/commons/thumb/3/3b/Oil_absorption_by_BN_aerogel.jpg/120px-Oil_absorption_by_BN_aerogel.jpg)

![An aerogel held up by hair.[81] (Scientific Reports)](http://upload.wikimedia.org/wikipedia/commons/thumb/6/6d/BN_aerogel_on_hair.jpg/120px-BN_aerogel_on_hair.jpg)