Titanium nitride

| |

| |

| Names | |

|---|---|

| IUPAC name

Titanium nitride

| |

| Other names

Titanium(III) nitride

| |

| Identifiers | |

3D model (

JSmol ) |

|

ECHA InfoCard

|

100.042.819 |

| EC Number |

|

PubChem CID

|

|

| UNII | |

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| TiN | |

| Molar mass | 61.874 g/mol |

| Appearance | Brown as a pure solid, coating of golden color |

| Odor | Odorless |

| Density | 5.21 g/cm3[1] |

| Melting point | 2,947 °C (5,337 °F; 3,220 K)[1] |

| insoluble | |

| +38×10−6 emu/mol | |

Thermal conductivity

|

29 W/(m·K) (323 K)[2] |

| Structure[3] | |

Face-centered cubic (FCC), cF8

| |

| Fm3m, No. 225 | |

a = 0.4241 nm

| |

Formula units (Z)

|

4 |

| Octahedral | |

| Thermochemistry | |

Heat capacity (C)

|

24 J/(K·mol) (500 K)[2] |

Std molar

entropy (S⦵298) |

−95.7 J/(K·mol)[4] |

Std enthalpy of (ΔfH⦵298)formation |

−336 kJ/mol[4] |

| Related compounds | |

Related coating

|

Titanium aluminum nitride

|

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Titanium nitride (TiN; sometimes known as tinite) is an extremely hard

components to improve the substrate's surface properties.Applied as a thin coating, TiN is used to harden and protect cutting and sliding surfaces, for decorative purposes (for its golden appearance), and as a non-toxic exterior for medical implants. In most applications a coating of less than 5 micrometres (0.00020 in) is applied.[5]

Characteristics

TiN has a

TiN will oxidize at 800 °C in a normal atmosphere. TiN has a brown color, and appears gold when applied as a coating. It is chemically stable at 20 °C, according to laboratory tests, but can be slowly attacked by concentrated acid solutions with rising temperatures.[7] Depending on the substrate material and surface finish, TiN will have a

TiN becomes

Natural occurrence

Osbornite is a very rare natural form of titanium nitride, found almost exclusively in meteorites.[12][13]

Uses

A well-known use for TiN coating is for edge retention and corrosion resistance on machine tooling, such as drill bits and milling cutters, often improving their lifetime by a factor of three or more.[14]

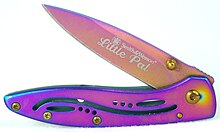

Because of the metallic gold color of TiN, this material is used to coat

Though less visible,

Owing to their high biostability, TiN layers may also be used as electrodes in

Fabrication

The most common methods of TiN thin film creation are

Bulk ceramic objects can be fabricated by packing powdered metallic titanium into the desired shape, compressing it to the proper density, then igniting it in an atmosphere of pure nitrogen. The heat released by the chemical reaction between the metal and gas is sufficient to sinter the nitride reaction product into a hard, finished item. See powder metallurgy.

Other commercial variants

There are several commercially used variants of TiN that have been developed since 2010, such as titanium carbon nitride (TiCN), titanium aluminium nitride (TiAlN or AlTiN), and titanium aluminum carbon nitride, which may be used individually or in alternating layers with TiN. These coatings offer similar or superior enhancements in corrosion resistance and hardness, and additional colors ranging from light gray to nearly black, to a dark, iridescent, bluish-purple, depending on the exact process of application. These coatings are becoming common on sporting goods, particularly knives and handguns, where they are used for both aesthetic and functional reasons.

As a constituent in steel

Titanium nitride is also produced intentionally, within some steels, by judicious addition of titanium to the

References

- ^ ISBN 9781498754293.

- ^ .

- .

- ^ .

- ^ "TiN (Titanium Nitride) – Surface Coating". Retrieved 2024-02-17.

- ^ doi:10.1116/1.577270.

- ^ ISBN 978-0-8155-1392-6– via Google Books.

- ISBN 978-0-12-695950-5.

- .

- S2CID 518088.

- ^ "Newly discovered 'superinsulators' promise to transform materials research, electronics design". PhysOrg.com. 2008-04-07.

- ^ "Osbornite". Mindat.org. Hudson Institute of Mineralogy. Retrieved Feb 29, 2016.

- ^ "Osbornite mineral data". Mineralogy Database. David Barthelmy. Sep 5, 2012. Retrieved Oct 6, 2015.

- ^ "Titanium Nitride (TiN) Coating". Surface Solutions. June 2014.

- ^ "Products". IonFusion Surgical. Retrieved 2009-06-25.

- S2CID 120728898.

- .

- .

- .

- PMID 11771699.

- .

- ^ "Wear coatings for industrial products". Diffusion Alloys. Archived from the original on 2013-05-19. Retrieved 2013-06-14.

- ^ "Coatings". Coating Services Group. Retrieved 2009-06-25.

- .