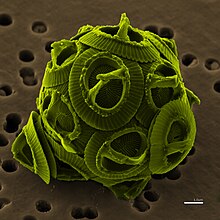

Culture of microalgae in hatcheries

The oldest documented use of microalgae was 2000 years ago, when the Chinese used the cyanobacteria Nostoc as a food source during a famine.[3] Another type of microalgae, the cyanobacteria Arthrospira (Spirulina), was a common food source among populations in Chad and Aztecs in Mexico as far back as the 16th century.[4]

Today cultured microalgae is used as direct feed for humans and land-based farm animals, and as feed for cultured aquatic species such as molluscs and the early larval stages of fish and crustaceans.[5] It is a potential candidate for biofuel production.[6] Microalgae can grow 20 or 30 times faster than traditional food crops, and has no need to compete for arable land.[6][7] Since microalgal production is central to so many commercial applications, there is a need for production techniques which increase productivity and are economically profitable.

Commonly cultivated microalgae species

| Species | Application |

|---|---|

| Chaetoceros sp.[8] | Aquaculture[8] |

| Chlorella vulgaris[9] | Source of natural antioxidants, [9] high protein content

|

| Dunaliella salina[10] | Produce β-carotene)[10]

|

| Haematococcus sp.[11] | Produce |

| Phaeodactylum tricornutum[9] | Source of antioxidants[9] |

| Porphyridium cruentum[9] | Source of antioxidants[9]

|

| Rhodella sp.[8] | Colourant for cosmetics[8] |

| Skeletonema sp[8] | Aquaculture[8] |

| Arthrospira maxima[12] | High protein content – Nutritional supplement[12] |

| Arthrospira platensis[12] | High protein content – Nutritional supplement[12] |

Hatchery production techniques

A range of microalgae species are produced in hatcheries and are used in a variety of ways for commercial purposes. Studies have estimated main factors in the success of a microalgae hatchery system as the dimensions of the container/bioreactor where microalgae is cultured, exposure to light/irradiation and concentration of cells within the reactor.[13]

Open pond system

This method has been employed since the 1950s across the CONUS.

Air-lift method

This method is used in outdoor cultivation and production of microalgae; where air is moved within a system in order to circulate water where microalgae is growing.[15] The culture is grown in transparent tubes that lie horizontally on the ground and are connected by a network of pipes.[15] Air is passed through the tube such that air escapes from the end that rests inside the reactor that contains the culture and creates an effect like stirring.[15]

Closed reactors

The biggest advantage of culturing microalgae within a closed system provides control over the physical, chemical and biological environment of the culture.

Horizontal photobioreactors

This system includes tubes laid on the ground to form a network of loops. Mixing of microalgal suspended culture occurs through a pump that raises the culture vertically at timed intervals into a photobioreactor. Studies have found pulsed mixing at intervals produces better results than the use of continuous mixing. Photobioreactors have also been associated with better production than open pond systems as they can maintain better temperature gradients.[13] An example noted in higher production of Arthrospira sp. used as a dietary supplement was attributed to higher productivity because of a better suited temperature range and an extended cultivation period over summer months.[13]

Vertical systems

These reactors use vertical polyethylene sleeves hung from an iron frame. Glass tubes can also be used alternatively. Microalgae are also cultured in vertical alveolar panels (VAP) that are a type of photobioreactor.[13] This photobioreactor is characterised by low productivity. However, this problem can be overcome by modifying the surface area to volume ratio; where a higher ratio can increase productivity.[13] Mixing and deoxygenation are drawbacks of this system and can be addressed by bubbling air continuously at a mean flow rate. The two main types of vertical photobioreactors are the Flow-through VAP and the Bubble Column VAP.[13]

In darkness

By using an electrocatalytic process to produce acetate from water, electricity and carbon dioxide, which is then used by the algae as food source, sunlight and photosynthesis is no longer required. The method is still at an early stage, but experiments with algae like Chlamydomonas reinhardtii have turned out to be promising.[21][22]

Flat plate reactors

Flat plate reactors(FPR) are built using narrow panels and are placed horizontally to maximise sunlight input to the system.

Fermentor-type reactors

Fermentor-type reactors (FTR) are bioreactors where

Commercial applications

Use in aquaculture

Microalgae is an important source of nutrition and is used widely in the aquaculture of other organisms, either directly or as an added source of basic nutrients. Aquaculture farms rearing larvae of molluscs, echinoderms, crustaceans and fish use microalgae as a source of nutrition. Low bacteria and high microalgal biomass is a crucial food source for shellfish aquaculture.[25]

Microalgae can form the start of a chain of further aquaculture processes. For example, microalgae is an important food source in the

Other applications of microalgae within aquaculture include increasing the

Human nutrition

The main species of microalgae grown as health foods are

Production of

Australian scientists at

Biofuel production

In order to meet the demands of

Pharmaceuticals and cosmetics

Novel

Red microalgae are characterised by pigments called

Biofertilizer

Blue green alga was first used as a means of fixing nitrogen by allowing

Other uses

Microalgae are a source of valuable molecules such as

Issues

Cell fragility is the biggest issue that limits the productivity from closed

See also

- Algae fuel

- Microbiofuels

References

- S2CID 92558441.

- ^ PMID 18221809. Archived from the original(PDF) on 2022-05-13. Retrieved 2011-09-30.

- S2CID 16896655. Archived from the original(PDF) on 2012-04-03. Retrieved 2011-10-13.

- ISBN 978-0-7923-4735-4.

- ISBN 978-0-13-482316-4.

- ^ PMID 20031983.

- ^ McDill, Stuart (2009-02-10). "Can algae save the world – again?". Reuters. Retrieved 2009-02-10.

- ^ S2CID 85366788.

- ^ PMID 26065767.

- ^ .

- ^ .

- ^ ISBN 978-0-7923-4735-4.

- ^ S2CID 20554506.

- S2CID 219431866.

- ^ ISBN 978-0-8493-3240-1.

- S2CID 115448212.

- ^ Microalgal biorefinery from CO2 and the effects under the Blue Economy: pdf download

- ^ Culture of microalga Spirulina platensis in alternative sources of nutrients

- S2CID 146179919.

- S2CID 134527132.

- ^ Cultivating Crops, No Sun Required - Modern Farmer

- S2CID 250004816.

- ^ S2CID 10362553.

- PMID 11173093.

- ^ S2CID 8495961.

- OCLC 222006176.

- .

- PMID 10740262.

- S2CID 42873936.

- ^ Yenni Kwok. "The Imp With a Mighty Kick". Asia Week. CNN.tv.

- ^ "Aphanizomenon Flos-Aquae Blue Green Algae". Energy For Life Wellness Center. Archived from the original on 2006-04-26. Retrieved 2006-08-29.

- ^ "Nutritional value of micro-algae". United States Fisheries Department. Archived from the original on 26 August 2006. Retrieved 2006-08-29.

- ^ "Chlorella Growth Factor, nutritional supplement".

- S2CID 8634817.

- ^ Leckie, Evelyn (14 Jan 2021). "Adelaide scientists turn marine microalgae into 'superfoods' to substitute animal proteins". ABC News. Australian Broadcasting Corporation. Retrieved 17 Jan 2021.

- .

- .

- ^ doi:10.17221/384-PSE.

- ^ S2CID 121561783.

- S2CID 9060288.

- ^ .

- ^ .