Pulp (paper)

Pulp is a fibrous lignocellulosic material prepared by chemically, semi-chemically or mechanically produced by cellulosic fibers from wood, fiber crops, waste paper, or rags. Mixed with water and other chemicals or plant-based additives, pulp is the major raw material used in papermaking and the industrial production of other paper products.[1][2]

History

Before the widely acknowledged invention of

The use of wood pulp and the invention of automatic

Global production of wood pulp in 2006 was 175 million tons (160 million tonnes).

Wood pulp

The

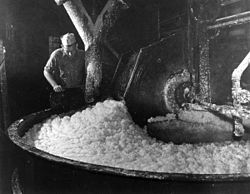

A pulp mill is a manufacturing facility that converts wood chips or other plant fibre source into a thick fiberboard which can be shipped to a paper mill for further processing. Pulp can be manufactured using mechanical, semi-chemical or fully chemical methods (kraft and sulfite processes). The finished product may be either bleached or non-bleached, depending on the customer requirements.

Wood and other plant materials used to make pulp contain three main components (apart from water): cellulose fibers (desired for papermaking), lignin (a three-dimensional polymer that binds the cellulose fibres together) and hemicelluloses (shorter branched carbohydrate polymers). The aim of pulping is to break down the bulk structure of the fibre source, be it chips, stems or other plant parts, into the constituent fibres.

Chemical pulping achieves this by degrading the lignin and hemicellulose into small, water-soluble molecules which can be washed away from the cellulose fibres without depolymerizing the cellulose fibres (chemically depolymerizing the cellulose weakens the fibres). The various mechanical pulping methods, such as groundwood (GW) and refiner mechanical pulping (RMP), physically tear the cellulose fibres one from another. Much of the lignin remains adhering to the fibres. Strength is impaired because the fibres may be cut. There are a number of related hybrid pulping methods that use a combination of chemical and thermal treatment to begin an abbreviated chemical pulping process, followed immediately by a mechanical treatment to separate the fibres. These hybrid methods include thermomechanical pulping, also known as TMP, and chemithermomechanical pulping, also known as CTMP. The chemical and thermal treatments reduce the amount of energy subsequently required by the mechanical treatment, and also reduce the amount of strength loss suffered by the fibres.

| Pulp category | Production [M ton] |

| Chemical | 131.2 |

| Kraft | 117.0 |

| Sulfite | 7.0 |

| Semichemical | 7.2 |

| Mechanical | 37.8 |

| Nonwood | 18.0 |

| Total virgin fibres | 187.0 |

| Recovered fibres | 147.0 |

| Total pulp | 334.0 |

Harvesting trees

Most pulp mills use good

The number of trees consumed depends on whether mechanical processes or chemical processes are used. It has been estimated that based on a mixture of softwoods and hardwoods 12 metres (40 ft) tall and 15–20 centimetres (6–8 in) in diameter, it would take an average of 24 trees to produce 0.9 tonne (1 ton) of printing and writing paper, using the kraft process (chemical pulping). Mechanical pulping is about twice as efficient in using trees, since almost all of the wood is used to make fibre, therefore it takes about 12 trees to make 0.9 tonne (1 ton) of mechanical pulp or newsprint.[23]

There are roughly two short tons in a cord of wood.[24]

Preparation for pulping

Wood chipping is the act and industry of chipping wood for pulp, but also for other

Pulping

There are a number of different processes which can be used to separate the wood fiber:

Mechanical pulp

Manufactured

Thermomechanical pulp

Thermomechanical pulp is pulp produced by processing

Chemi-thermomechanical pulp

Wood chips can be pre-treated with sodium carbonate, sodium hydroxide, sodium sulfate and other chemicals prior to refining with equipment similar to a mechanical mill. The conditions of the chemical treatment are much less vigorous (lower temperature, shorter time, less extreme pH) than in a chemical pulping process since the goal is to make the fibers easier to refine, not to remove lignin as in a fully chemical process. Pulps made using these hybrid processes are known as chemi-thermomechanical pulps (CTMP).

Chemical pulp

Chemical pulp is produced by combining wood chips and chemicals in large vessels called digesters. There, heat and chemicals break down lignin, which binds

Recycled pulp

Recycled pulp is also called deinked pulp (DIP). DIP is

DIP is used as raw material in papermaking. Many newsprint, toilet paper and facial tissue grades commonly contain 100 percent deinked pulp and in many other grades, such as lightweight coated for offset and printing and writing papers for office and home use, DIP makes up a substantial proportion of the furnish.

Organosolv pulping

Organosolv pulping uses organic solvents at temperatures above 140 °C to break down lignin and hemicellulose into soluble fragments. The pulping liquor is easily recovered by distillation. The reason for using a solvent is to make the lignin more soluble in the cooking liquor. Most common used solvents are methanol, ethanol, formic acid and acetic acid often in combination with water.

Alternative pulping methods

Research is under way to develop biopulping (biological pulping), similar to chemical pulping but using certain species of fungi that are able to break down the unwanted lignin, but not the cellulose fibres.[26] In the biopulping process, the fungal enzyme lignin peroxidase selectively digests lignin to leave remaining cellulose fibres. This could have major environmental benefits in reducing the pollution associated with chemical pulping. The pulp is bleached using chlorine dioxide stage followed by neutralization and calcium hypochlorite. The oxidizing agent in either case oxidizes and destroys the dyes formed from the tannins of the wood and accentuated (reinforced) by sulfides present in it.

Steam exploded fibre is a pulping and extraction technique that has been applied to wood and other fibrous organic material.[27]

Bleaching

The pulp produced up to this point in the process can be bleached to produce a white paper product. The chemicals used to bleach pulp have been a source of environmental concern, and recently the pulp industry has been using alternatives to chlorine, such as chlorine dioxide, oxygen, ozone and hydrogen peroxide.

Alternatives to wood pulp

Pulp made from non-wood plant sources or

Today, some groups advocate using field crop fibre or agricultural residues instead of wood fibre as a more sustainable means of production.[citation needed]

There is enough

Hemp paper is a possible replacement, but processing infrastructure, storage costs and the low usability percentage of the plant means it is not a ready substitute.[citation needed]

However, wood is also a renewable resource, with about 90 percent of pulp coming from plantations or reforested areas.[21] Non-wood fibre sources account for about 5–10 percent of global pulp production, for a variety of reasons, including seasonal availability, problems with chemical recovery, brightness of the pulp etc.[16][34] In China, as of 2009, a higher proportion of non-wood pulp processing increased use of water and energy.[35]

| Component | Wood | Nonwood |

|---|---|---|

| Carbohydrates | 65–80% | 50–80% |

|

40–45% | 30–45% |

|

23–35% | 20–35% |

| Lignin | 20–30% | 10–25% |

| Extractives | 2–5% | 5–15% |

| Proteins | <0.5% | 5–10% |

| Inorganics | 0.1–1% | 0.5–10% |

|

<0.1% | 0.5–7% |

Market pulp

Market pulp is any variety of pulp that is produced in one location, dried and shipped to another location for further processing.

Air dry pulp is the most common form to sell pulp. This is pulp dried to about 10 percent moisture content. It is normally delivered as sheeted bales of 250 kg. The reason to leave 10 percent moisture in the pulp is that this minimizes the fibre to fibre bonding and makes it easier to disperse the pulp in water for further processing to paper.[37]

Roll pulp or reel pulp is the most common delivery form of pulp to non traditional pulp markets. Fluff pulp is normally shipped on rolls (reels). This pulp is dried to 5–6 percent moisture content. At the customer this is going to a comminution process to prepare for further processing.[37]

Some pulps are flash dried. This is done by pressing the pulp to about 50 percent moisture content and then let it fall through silos that are 15–17 m high. Gas fired hot air is the normal heat source. The temperature is well above the char point of cellulose, but large amount of moisture in the fibre wall and lumen prevents the fibres from being incinerated. It is often not dried down to 10 percent moisture (air dry). The bales are not as densely packed as air dry pulp.[37]

Environmental concerns

The major environmental impacts of producing wood pulp come from its impact on forest sources and from its waste products.

Forest resources

The impact of logging to provide the raw material for wood pulp is an area of intense debate. Modern

Effluents from pulp mills

The process effluents are treated in a biological effluent treatment plant, which guarantees that the effluents are not toxic in the recipient.

Mechanical pulp is not a major cause for environmental concern since most of the organic material is retained in the pulp, and the chemicals used (hydrogen peroxide and sodium dithionite) produce benign byproducts (water and sodium sulfate (finally), respectively).

Chemical pulp mills, especially kraft mills, are energy self-sufficient and very nearly closed cycle with respect to inorganic chemicals.

Odor problems

The kraft pulping reaction in particular releases foul-smelling compounds. The sulfide reagent that degrades lignin structure also causes some demethylation, yielding

Applications

The main applications for pulp are paper and board production. The furnish of pulps used depends on the quality on the finished paper. Important quality parameters are wood furnish, brightness, viscosity, extractives, dirt count and strength.

Chemical pulps are used for making nanocellulose.[citation needed]

Speciality pulp grades have many other applications.

Paper production

The Fourdrinier Machine is the basis for most modern papermaking, and it has been used in some variation since its conception. It accomplishes all the steps needed to transform pulp into a final paper product.

Economics

In 2009,

See also

- Nanocellulose

- Paper chemicals

- Pulp mill

- Pulpwood

- Tree-free paper

- Johan Richter, developer of the process for continuous cooking of pulp

- World Forestry Congress

References

- ^ a b c d Hunter, Dard (1943). Papermaking, the history and technique of an ancient craft. Dover.

- ^ ISBN 0-12-097360-X.

- S2CID 162420219.

- ISBN 978-3-86527-836-4

- ^ a b "papermaking | Process, History, & Facts". Encyclopedia Britannica. Retrieved 2020-04-15.

- ^ Tsien, Tsuen-Hsuin (1985), Paper and Printing, Science and Civilisation in China: Chemistry and Chemical Technology, vol. 5 Part 1, Cambridge University Press, p. 4

- ^ a b Tsien, Tsuen-Hsuin (1985), Paper and Printing, Science and Civilisation in China: Chemistry and Chemical Technology, vol. 5 Part 1, Cambridge University Press, pp. 56–61

- ^ a b Bowyer, Jim (August 19, 2014). "Tree-free Paper: A Path to Saving Trees and Forests?" (PDF). Retrieved April 15, 2020.

- ^ ISBN 978-0-9783318-1-8pp.25–30

- ISBN 978-3-527-30673-2

- doi:10.58079/tcxz. Retrieved 2020-04-15.

- ^ a b Sjöström, E. (1993). Wood Chemistry: Fundamentals and Applications. Academic Press.

- ^ History of Paper. indiapapermarket.com

- ^ "Pulp production growing in new areas (Global production)". Metso Corporation. September 5, 2006. Archived from the original on October 23, 2007. Retrieved 2007-10-13.

- ISBN 3-527-30999-3.

- ^ a b "Overview of the Wood Pulp Industry". Market Pulp Association. 2007. Archived from the original on 2007-10-16. Retrieved 2007-10-13.

- ^ Manthy, Robert S.; James, Lee Morton; Huber, Henry H. (1973). Michigan Timber Production: Now and in 1985. Michigan State University, Agricultural Experiment Station and Cooperative Extension service.

- ^ "Paper". How Products are Made.

- ISBN 9781118827376.

- ISBN 3-527-30997-7.

- ^ a b c Martin, Sam (2004). "Paper Chase". Ecology Communications, Inc. Archived from the original on 2007-06-19. Retrieved 2007-09-21.

- ^ "Certification Tracking products from the forest to the shelf". Archived from the original on 2007-08-26. Retrieved 2007-09-21.

- ^ Trees Into Paper. Conservatree. Retrieved on 2017-01-09.

- ^ "dead link". Archived from the original on 2008-12-25. Retrieved 2009-02-05.

- ^ a b Paperboard the Iggesund Way (Report). Iggesund Paperboard AB. 2008. p. 15. Archived from the original on 2021-04-30. Retrieved 2020-04-16.

- ^ Husaini, Ahmad; Fisol, Faisalina Ahmad; Yun, Liew Chia; Hussain, Mohd Hasnain; Muid, Sepiah; Roslan, Hairul Azman (2011). "Lignocellulolytic enzymes produced by tropical white rot fungi during biopulping of Acacia mangium wood chips". J Biochem Tech. 3 (2): 245–250. Archived from the original on 2017-01-09. Retrieved 2017-01-09.

- .

- ^ McCrady, Ellen (November 1991). "The Nature of Lignin". cool.culturalheritage.org. Retrieved 2020-04-15.

- ^ Burge, Daniel M. (2002). "Effects of enclosure papers and paperboards containing lignins on photographic image stability". cool.culturalheritage.org. Retrieved 2020-04-15.

- ^ "Markets". delarue.com. Archived from the original on 2012-05-13. Retrieved 2017-07-14.

- ^ "Banknotes design and production". Bank of Canada. Archived from the original on December 16, 2008. Retrieved February 7, 2009.

- ^ "How Money is Made – Paper and Ink". Bureau of Engraving and Printing U.S. Department of the Treasury. Retrieved July 14, 2017.

- ^ "Canopy's Straw Paper Campaign". canopyplanet.org. Archived from the original on 2013-09-03.

- ^ Judt, Manfred (Oct–Dec 2001). "Nonwoody Plant Fibre Pulps". Inpaper International. Archived from the original on 2007-11-20. Retrieved 2007-10-07.

- ^ 造纸企业能入“绿色之门”的前提 南粤大地 南方网. News.southcn.com (2009-07-20). Retrieved on 2017-01-09.

- ISBN 952-5216-03-9.

- ^ ISBN 0-615-13013-5.

- PMID 31444645.

- ISBN 0-662-18734-2. Retrieved 2007-09-21.

- ISSN 1573-1553.

- PMID 13904415.

- ^ Lefebrvre, Paul (February 4, 2009). Wood products market looks soft. The Chronicle.

- ^ "Current Lumber Pulp Panel Prices". Natural Resources Canada/Our Natural Resources/Domestic and international markets. Government of Canada. 2024-01-17. Retrieved 2024-01-22.

Bibliography

- "Pulp and Paper", Environment Canada, Government of Canada, 2014, archived from the original on 2016-04-21, retrieved 2014-03-31

- Schäffer, Jacob Christian (1765). Versuche und Muster ohne alle Lumpen oder doch mit enem geringen Zusatze derselben Papier zu machen.