Polylactic acid

| |

| Identifiers | |

|---|---|

| ChemSpider |

|

CompTox Dashboard (EPA)

|

|

| Properties | |

| Density | 1210–1430 kg/m3[1] |

| Melting point | 150 to 160 °C (302 to 320 °F; 423 to 433 K)[1] |

| 0 mg/ml [2] | |

| Hazards | |

| NFPA 704 (fire diamond) | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

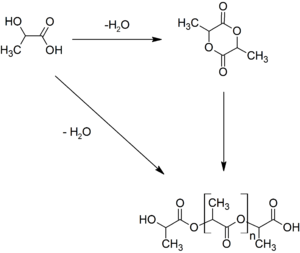

Polylactic acid, also known as poly(lactic acid) or polylactide (PLA), is a thermoplastic polyester with backbone formula (C

3H

4O

2)

n or [–C(CH

3)HC(=O)O–]

n, formally obtained by condensation of lactic acid C(CH

3)(OH)HCOOH with loss of water (hence its name). It can also be prepared by ring-opening polymerization of lactide [–C(CH

3)HC(=O)O–]

2, the cyclic dimer of the basic repeating unit.

PLA has become a popular material due to it being economically produced from renewable resources. In 2021, PLA had the highest consumption volume of any bioplastic of the world,[3] although it is still not a commodity polymer. Its widespread application has been hindered by numerous physical and processing shortcomings.[4] PLA is the most widely used plastic filament material in FDM 3D printing, due to its low melting point, high strength, low thermal expansion, and good layer adhesion, although it possesses poor heat resistance unless annealed.[5][6]

Although the name "polylactic acid" is widely used, it does not comply with

Chemical properties

Synthesis

The monomer is typically made from fermented plant starch such as from corn, cassava, sugarcane or sugar beet pulp.

Several industrial routes afford usable (i.e. high molecular weight) PLA. Two main monomers are used:

The direct condensation of lactic acid monomers can also be used to produce PLA. This process needs to be carried out at less than 200 °C; above that temperature, the entropically favored lactide monomer is generated. This reaction generates one equivalent of water for every condensation (

Another method devised is by contacting lactic acid with a zeolite. This condensation reaction is a one-step process, and runs about 100 °C lower in temperature.[10][11]

Stereoisomers

Due to the chiral nature of lactic acid, several distinct forms of polylactide exist: poly-L-lactide (PLLA) is the product resulting from polymerization of L,L-lactide (also known as L-lactide). Progress in biotechnology has resulted in the development of commercial production of the D enantiomer form.[12]

Polymerization of a

The direct biosynthesis of PLA, in a manner similar to production of

Physical properties

PLA polymers range from amorphous glassy polymer to semi-crystalline and highly crystalline polymer with a

Although PLA performs mechanically similar to PET for properties of

Several technologies such as

Backbone architecture of PLA and its effect on crystallization kinetics has also been investigated, specifically to better understand the most suitable processing conditions for PLA. The molecular weight of polymer chains can play a significant role in the mechanical properties.[32] One method of increasing molecular weight is by introducing branches of the same polymer chain onto the backbone. Through characterization of a branched and linear grade PLA, branched PLA leads to faster crystallization.[33] Furthermore, the branched PLA experiences much longer relaxation times at low shear rates, contributing to higher viscosity than the linear grade. This is presumed to be from high molecular weight regions within the branched PLA. However, the branched PLA was observed to shear thin more strongly, leading to a much lower viscosity at high shear rates. Understanding properties such as these are crucial when determining optimal processing conditions for materials, and that simple changes to the structure can alter its behavior dramatically.

Racemic PLA and pure PLLA have low glass transition temperatures, making them undesirable because of low strength and melting point. A stereocomplex of PDLA and PLLA has a higher glass transition temperature, lending it more mechanical strength.[34]

The high surface energy of PLA results in good printability, making it widely used in 3D printing. The tensile strength for 3D printed PLA was previously determined.[35]

Solvents

PLA is soluble in a range of organic solvents.[36] Ethyl acetate is widely used because of its ease of access and low risk. It is useful in 3D printers for cleaning the extruder heads and for removing PLA supports.

Other safe solvents include

Fabrication

PLA objects can be fabricated by 3D printing, casting, injection moulding, extrusion, machining, and solvent welding.

PLA is used as a feedstock material in desktop fused filament fabrication by 3D printers, such as RepRap printers.[38][39]

PLA can be solvent welded using dichloromethane.[40] Acetone also softens the surface of PLA, making it sticky without dissolving it, for welding to another PLA surface.[41]

PLA-printed solids can be encased in plaster-like moulding materials, then burned out in a furnace, so that the resulting void can be filled with molten metal. This is known as "lost PLA casting", a type of investment casting.[42]

Applications

Consumer goods

PLA is used in a large variety of consumer products such as

PLA has applications in engineering plastics, where the stereocomplex is blended with a rubber-like polymer such as ABS. Such blends have good form stability and visual transparency, making them useful in low-end packaging applications.

PLA is used for automotive parts such as floor mats, panels, and covers. Its heat resistance and durability are inferior to the widely used polypropylene (PP), but its properties are improved by means such as capping of the end groups to reduce hydrolysis.[43]

Agricultural

In the form of fibers, PLA is used for monofilament fishing line and netting for vegetation and weed prevention. It is used for sandbags, planting pots, binding tape and ropes .[43]

Medical

PLA can degrade into innocuous lactic acid, making it suitable for use as medical implants in the form of anchors, screws, plates, pins, rods, and mesh.[43] Depending on the type used, it breaks down inside the body within 6 months to 2 years. This gradual degradation is desirable for a support structure, because it gradually transfers the load to the body (e.g., to the bone) as that area heals. The strength characteristics of PLA and PLLA implants are well documented.[44]

Thanks to its bio-compatibility and biodegradability, PLA found interest as a polymeric scaffold for drug delivery purposes.

The composite blend of poly(L-lactide-co-D,L-lactide) (PLDLLA) with tricalcium phosphate (TCP) is used as PLDLLA/TCP scaffolds for bone engineering.[45][46]

Poly-L-lactic acid (PLLA) is the main ingredient in Sculptra, a facial volume enhancer used for treating lipoatrophy of the cheeks.

PLLA is used to stimulate collagen synthesis in fibroblasts via foreign body reaction in the presence of macrophages. Macrophages act as a stimulant in secretion of cytokines and mediators such as TGF-β, which stimulate the fibroblast to secrete collagen into the surrounding tissue. Therefore, PLLA has potential applications in the dermatological studies.[47][48]

PLLA is under investigation as a scaffold that can generate a small amount of

-

Mulch film made of PLA-blend "bio-flex"

-

Biodegradable PLA cups

-

Tea bags made of PLA. Peppermint tea is enclosed.

-

-

3D printed human skull with data fromcomputed tomography. Transparent PLA.

Degradation

PLA is degraded abiotically by three mechanisms:[51]

- Hydrolysis: The ester groups of the main chain are cleaved, thus reducing molecular weight.

- Thermal decomposition: A complex phenomenon leading to the appearance of different compounds such as lighter molecules and linear and cyclic oligomers with different Mw, and lactide.

- Photodegradation: UV radiation induces degradation. This is a factor mainly where PLA is exposed to sunlight in its applications in plasticulture, packaging containers and films.

The hydrolytic reaction is:

- -COO- + H2O → -COOH + -OH

The degradation rate is very slow in ambient temperatures. A 2017 study found that at 25 °C (77 °F) in seawater, PLA showed no loss of mass over a year, but the study did not measure breakdown of the polymer chains or water absorption.[52] As a result, it degrades poorly in landfills and household composts, but is effectively digested in hotter industrial composts, usually degrading best at temperatures of over 60 °C (140 °F).[53]

Pure PLA foams are selectively hydrolysed in Dulbecco's modified Eagle's medium (DMEM) supplemented with fetal bovine serum (FBS) (a solution mimicking body fluid). After 30 days of submersion in DMEM+FBS, a PLLA scaffold lost about 20% of its weight.[54]

PLA samples of various molecular weights were degraded into methyl lactate (a green solvent) by using a metal complex catalyst.[55][56][57]

PLA can also be degraded by some bacteria, such as

End of life

Four possible end-of-life scenarios are the most common:

- Recycling:[59] which can be either chemical or mechanical. Currently, the SPI resin identification code 7 ("others") is applicable for PLA. In Belgium, Galactic started the first pilot unit to chemically recycle PLA (Loopla).[60] Unlike mechanical recycling, waste material can hold various contaminants. Polylactic acid can be chemically recycled to monomer by thermal depolymerization or hydrolysis. When purified, the monomer can be used for the manufacturing of virgin PLA with no loss of original properties[61] (cradle-to-cradle recycling).[dubious ] End-of-life PLA can be chemically recycled to methyl lactate by transesterification.[57]

- industrial composting conditions (58 °C (136 °F)), PLA can partly (about half) decompose into water and carbon dioxide in 60 days, after which the remainder decomposes much more slowly,[62] with the rate depending on the material's degree of crystallinity.[63] Environments without the necessary conditions will see very slow decomposition akin to that of non-bioplastics, not fully decomposing for hundreds or thousands of years.[64]

- Incineration: PLA can be incinerated without producing chlorine-containing chemicals or heavy metals because it contains only carbon, oxygen, and hydrogen atoms. Since it does not contain chlorine it does not produce dioxins or hydrochloric acid during incineration.[65] PLA can be combusted with no remaining residue. This and other results suggest that incineration is an environmentally friendly disposal of waste PLA.[66] Upon being incinerated, PLA can release carbon dioxide.[67]

- Landfill: the least preferable option is landfilling because PLA degrades very slowly in ambient temperatures, often as slowly as other plastics.[64]

See also

- Acrylonitrile butadiene styrene (ABS) - also used for 3D printing

- poly-3-hydroxybutyrate– biologically derived polymers

- Polilactofate

- Polycaprolactone

- Zein, shellac – biologically derived coating materials

- Poly(methyl methacrylate)

References

- ^ a b "Material Properties of Polylactic Acid (PLA), Agro Based Polymers". Matbase - Material Properties Database. Archived from the original on 10 February 2012. Retrieved 6 February 2012.

- ^ "Polylactic Acid. Material Safety Data Sheet" (PDF). ampolymer.com. Archived from the original (PDF) on 6 January 2009.

- ^ Ceresana. "Bioplastics - Study: Market, Analysis, Trends - Ceresana". www.ceresana.com. Archived from the original on 4 November 2017. Retrieved 22 November 2022.

- .

- ^ "Worldwide most used 3D printing materials, as of July 2018". Retrieved 19 January 2024.

- ^ S2CID 195550926.

- .

- .

- ^ ISBN 978-0-470-64984-8.

- ^ Drury J (15 February 2016). "Cheaper, greener, route to bioplastic". reuters.com. Archived from the original on 1 December 2017. Retrieved 9 May 2018.

- S2CID 206635718.

- ^ "Bioengineers succeed in producing plastic without the use of fossil fuels". Physorg.com. Archived from the original on 6 June 2011. Retrieved 11 April 2011.

- S2CID 95429767.

- S2CID 205499487.

- ^ ISSN 0141-3910.

- .

- PMID 11055281.

- .

- PMID 34199577.

- PMID 27356150.

- PMID 28466854.

- ISSN 0141-3910.

- ISSN 0032-3861.

- ISSN 0032-3861.

- ISSN 1438-7492.

- S2CID 98078359.

- ISSN 1438-7492.

- S2CID 98536537.

- ISSN 1438-7492.

- PMID 32938000.

- ^ "Compare Materials: PLA and PETE". Makeitfrom.com. Archived from the original on 1 May 2011. Retrieved 11 April 2011.

- ISSN 0032-3888.

- ISSN 1572-8900.

- PMID 32974273.

- PMID 8933291.

- .

- from the original on 26 May 2013.

- ^ "PLA". Reprap Wiki. 4 April 2011. Archived from the original on 16 July 2011. Retrieved 11 April 2011.

- ^ "PLA". MakerBot Industries. Archived from the original on 23 April 2011. Retrieved 11 April 2011.

- ^ Coysh A (12 April 2013). "Dichloromethane Vapor Treating PLA parts". Thingiverse.com. Archived from the original on 1 December 2017. Retrieved 9 May 2018.

- ^ Sanladerer T (9 December 2016). "Does Acetone also work for welding and smoothing PLA 3D printed parts?". youtube.com. Archived from the original on 21 December 2021. Retrieved 9 January 2021.

- ^ "Metal Casting with Your 3D Printer". Make: DIY Projects and Ideas for Makers. Retrieved 30 November 2018.

- ^ ISBN 978-0-470-29366-9.

- ISBN 978-0-8031-1897-3.

- S2CID 135582844.

- .

- S2CID 236199608.

- PMID 32722074.

- ^ Petersen M (18 January 2022). "Electric knee implants could help millions of arthritis patients". ZME Science. Retrieved 19 January 2022.

- PMID 25793923.

- PMID 27046295.

- PMID 31565274.

- ^ "Is PLA Biodegradable? – The Truth". All3DP. 10 December 2019. Retrieved 26 June 2021.

- PMID 17975822.

- .

- S2CID 207941305.

- ^ PMID 32581423.

- PMID 19865515.

- S2CID 252665567.

- ^ "Chemical recycling closes the LOOPLA for cradle-to-cradle PLA". 20 November 2015.

- ISBN 978-3-319-64229-1.

- .

- .

- ^ a b "How long does it take for plastics to biodegrade?". HowStuffWorks. 15 December 2010. Retrieved 9 March 2021.

- ^ "End of Life Options for Bioplastics – Recycling, Energy, Composting, Landfill - Bioplastics Guide | Bioplastics Guide". Archived from the original on 25 February 2021. Retrieved 9 March 2021.

- S2CID 34100178.

- S2CID 248715252.

External links