Sodium borohydride

| |||

| |||

| |||

| Names | |||

|---|---|---|---|

| IUPAC name

Sodium tetrahydridoborate(1–)

| |||

| Systematic IUPAC name

Sodium boranuide | |||

| Identifiers | |||

| |||

3D model (

JSmol ) |

|||

| ChEBI | |||

| ChemSpider | |||

ECHA InfoCard

|

100.037.262 | ||

| EC Number |

| ||

| 23167 | |||

| MeSH | Sodium+borohydride | ||

PubChem CID

|

|||

RTECS number

|

| ||

| UNII | |||

| UN number | 1426 | ||

CompTox Dashboard (EPA)

|

|||

| |||

| |||

| Properties | |||

| Na[BH4] | |||

| Molar mass | 37.83 g·mol−1 | ||

| Appearance | white crystals hygroscopic

| ||

| Density | 1.07 g/cm3[1] | ||

| Melting point | 400 °C (752 °F; 673 K)(decomposes)[1] | ||

| 550 g/L[1] | |||

| Solubility | soluble in liquid ammonia, amines, pyridine | ||

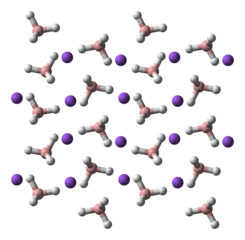

| Structure[2] | |||

| Cubic (NaCl), cF8 | |||

| Fm3m, No. 225 | |||

a = 0.6157 nm

| |||

| Thermochemistry[3] | |||

Heat capacity (C)

|

86.8 J·mol−1·K−1 | ||

Std molar

entropy (S⦵298) |

101.3 J·mol−1·K−1 | ||

Std enthalpy of (ΔfH⦵298)formation |

−188.6 kJ·mol−1 | ||

Gibbs free energy (ΔfG⦵)

|

−123.9 kJ·mol−1 | ||

| Hazards | |||

| GHS labelling:[4] | |||

| |||

| Danger | |||

| H260, H301, H314, H360F | |||

| P201, P231+P232, P280, P308+P313, P370+P378, P402+P404 | |||

| NFPA 704 (fire diamond) | |||

| Flash point | 70 °C (158 °F; 343 K) | ||

| ca. 220 °C (428 °F; 493 K) | |||

Explosive limits

|

3% | ||

| Lethal dose or concentration (LD, LC): | |||

LD50 (median dose)

|

160 mg/kg (Oral – Rat) 230 mg/kg (Dermal – Rabbit) | ||

| Related compounds | |||

Other anions

|

Sodium aluminum hydride

| ||

Other cations

|

Lithium borohydride | ||

Related compounds

|

Lithium aluminium hydride Sodium triacetoxyborohydride | ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |||

Sodium borohydride, also known as sodium tetrahydridoborate and sodium tetrahydroborate,

The compound was discovered in the 1940s by H. I. Schlesinger, who led a team seeking volatile uranium compounds.[7][8] Results of this wartime research were declassified and published in 1953.

Properties

The compound is soluble in alcohols, certain ethers, and water, although it slowly hydrolyzes.[9]

| Solvent | Solubility (g/(100 mL))[9] |

|---|---|

| CH3OH | 13 |

| CH3CH2OH | 3.16 |

| Diglyme | 5.15 |

| (CH3CH2)2O | insoluble |

Sodium borohydride is an odorless white to gray-white

Structure

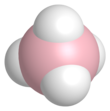

NaBH4 is a salt, consisting of the tetrahedral

-

α-NaBH4

-

β-NaBH4

-

γ-NaBH4

Synthesis and handling

For commercial NaBH4 production, the Brown-Schlesinger process and the Bayer process are the most popular methods. In the Brown-Schlesinger process sodium borohydride is industrially prepared from sodium hydride (produced by reacting Na and H2) and trimethyl borate at 250–270 °C:

- B(OCH3)3 + 4 NaH → NaBH4 + 3 NaOCH3

Millions of kilograms are produced annually, far exceeding the production levels of any other hydride reducing agent.[15] In the Bayer process, it is produced from inorganic borates, including borosilicate glass[16] and borax (Na2B4O7):

- Na2B4O7 + 16 Na + 8 H2 + 7 SiO2 → 4 NaBH4 + 7 Na2SiO3

Magnesium is a less expensive reductant, and could in principle be used instead:[17][18]

- 8 MgH2 + Na2B4O7 + Na2CO3 → 4 NaBH4 + 8 MgO + CO2

and

- 2 MgH2 + NaBO2 → NaBH4 + 2 MgO

Reactivity

Organic synthesis

NaBH4 reduces many organic carbonyls, depending on the conditions. Most typically, it is used in the laboratory for converting ketones and aldehydes to alcohols.[6] These reductions proceed in two stages, formation of the alkoxide followed by hydrolysis:

- NaBH4 + 4 R2C=O → NaO−CHR2 + B(O−CHR2)3

- NaO−CHR2 + B(O−CHR2)3 + 4 H2O → 4 HO−CHR2 + NaOH + B(OH)3

It also efficiently reduces acyl chlorides, anhydrides, α-hydroxylactones, thioesters, and imines at room temperature or below. It reduces esters slowly and inefficiently with excess reagent and/or elevated temperatures, while carboxylic acids and amides are not reduced at all.[19]

Nevertheless, an alcohol, often methanol or ethanol, is generally the solvent of choice for sodium borohydride reductions of ketones and aldehydes. The mechanism of ketone and aldehyde reduction has been scrutinized by kinetic studies, and contrary to popular depictions in textbooks, the mechanism does not involve a 4-membered transition state like alkene hydroboration,[20] or a six-membered transition state involving a molecule of the alcohol solvent.[21] Hydrogen-bonding activation is required, as no reduction occurs in an aprotic solvent like diglyme. However, the rate order in alcohol is 1.5, while carbonyl compound and borohydride are both first order, suggesting a mechanism more complex than one involving a six-membered transition state that includes only a single alcohol molecule. It was suggested that the simultaneous activation of the carbonyl compound and borohydride occurs, via interaction with the alcohol and alkoxide ion, respectively, and that the reaction proceeds through an open transition state.[22][23]

α,β-Unsaturated ketones tend to be reduced by NaBH4 in a 1,4-sense, although mixtures are often formed. Addition of cerium chloride improves the selectivity for 1,2-reduction of unsaturated ketones (Luche reduction). α,β-Unsaturated esters also undergo 1,4-reduction in the presence of NaBH4.[9]

The NaBH4-MeOH system, formed by the addition of methanol to sodium borohydride in refluxing THF, reduces esters to the corresponding alcohols.[24] Mixing water or an alcohol with the borohydride converts some of it into unstable hydride ester, which is more efficient at reduction, but the reductant eventually decomposes spontaneously to produce hydrogen gas and borates. The same reaction can also occur intramolecularly: an α-ketoester converts into a diol, since the alcohol produced attacks the borohydride to produce an ester of the borohydride, which then reduces the neighboring ester.[25]

The reactivity of NaBH4 can be enhanced or augmented by a variety of compounds.[26][27]

Many additives for modifying the reactivity of sodium borohydride have been developed as indicated by the following incomplete listing.

| additive | synthetic applications | page in Smith and March[28] | comment |

|---|---|---|---|

AlCl3 |

reduction of ketones to methylene | 1837 | |

BiCl3 |

converts epoxides to allylic alcohols | 1316 | |

| (C6H5Te)2 | reduction of nitroarenes | 1862 | |

| CeCl3 | reduction of ketones in the presence of aldehydes | 1794 | Luche reduction |

CoCl2 |

reduction of azides to amines | 1822 | |

InCl3 |

hydrogenolysis of alkyl bromides, double reduction of unsaturated ketones | 1825, 1793 | |

| LiCl | amine oxides to amines | 1846 | lithium borohydride |

| NiCl2 | deoxygenation of sulfoxides, hydrogenolysis of aryl tosylates, desulfurization, reduction of nitriles | 1851,1831, 991, 1814 | nickel boride

|

| TiCl4 | denitrosatation of nitrosamines | 1823 | |

| ZnCl2 | reduction of aldehydes | 1793 | |

ZrCl4 |

reduction of disulfides, reduction of azides to amines, cleavage of allyl aryl ethers | 1853, 1822, 582 |

Oxidation

Oxidation with iodine in tetrahydrofuran gives borane–tetrahydrofuran, which can reduce carboxylic acids to alcohols.[29]

Partial oxidation of borohydride with iodine gives octahydrotriborate:[30]

- 3 [BH4]− + I2 → [B3H8]− + 2 H2 + 2 I−

Coordination chemistry

[BH4]− is a

- 2 (C5H5)2TiCl2 + 4 NaBH4 → 2 (C5H5)2TiBH4 + 4 NaCl + B2H6 + H2

Protonolysis and hydrolysis

NaBH4 reacts with water and alcohols, with evolution of hydrogen gas and formation of the corresponding borate, the reaction being especially fast at low pH. Exploiting this reactivity, sodium borohydride has been studied as a prototypes of the direct borohydride fuel cell.

- NaBH4 + 2 H2O → NaBO2 + 4 H2 (ΔH < 0)

Applications

Paper manufacture

The dominant application of sodium borohydride is the production of sodium dithionite from sulfur dioxide: Sodium dithionite is used as a bleaching agent for wood pulp and in the dyeing industry.

It has been tested as pretreatment for pulping of wood, but is too costly to be commercialized.[15][32]

Chemical synthesis

Sodium borohydride

Niche or abandoned applications

Sodium borohydride has been considered as a way to

Although practical temperatures and pressures for hydrogen storage have not been achieved, in 2012 a core–shell nanostructure of sodium borohydride was used to store, release and reabsorb hydrogen under moderate conditions.[36]

Skilled professional conservator/restorers have used sodium borohydride to minimize or reverse foxing in old books and documents.[37]

See also

Many derivatives and analogues of sodium borohydride exhibit modified reactivity of value in organic synthesis.[38]

- Sodium triacetoxyborohydride, a milder reductant owing to the presence of more electron-withdrawing acetate in place of hydride.

- Sodium triethylborohydride, a stronger reductant owing to the presence of electron-donating ethyl groups in place of hydride.

- sodium cyanoborohydride, a milder reductant owing to the presence of more electron-withdrawing cyanide in place of hydride. Useful for reductive aminations.

- Lithium borohydride, a more strongly reducing reagent.

- L-selectride (lithium tri-sec-butylborohydride), a more strongly reducing derivative.

- Lithium aluminium hydride, a more strongly reducing reagent, capable of reducing esters and amides.

References

- ^ ISBN 978-1439855119.

- doi:10.1107/S0365110X54002034.)

{{cite journal}}: CS1 maint: multiple names: authors list (link - )

- ^ Record of Sodium borohydride in the GESTIS Substance Database of the Institute for Occupational Safety and Health, accessed on 2023-11-09.

- ISBN 9780470132869. Retrieved 20 May 2015.

- ^ ISBN 9780470842898.

- .

- ^ Hermann I Schlesinger and Herbert C Brown (1945) "Preparation of alkali metal compounds". US Patent 2461661. Granted on 1949-02-15; expired on 1966-02-15.

- ^ ISBN 978-0471936237.

- ISBN 0-471-11280-1. page 260-261

- .

- .

- S2CID 122588719.

- PMID 18031032.

- ^ OCLC 751968805.

- ^ Schubert, F.; Lang, K.; Burger, A. (1960) "Alkali metal borohydrides" (Bayer). German patent DE 1088930 19600915 (ChemAbs: 55:120851). Supplement to. to Ger. 1,067,005 (CA 55, 11778i). From the abstract: "Alkali metal borosilicates are treated with alkali metal hydrides in approx. 1:1 ratio at >100 °C with or without H pressure"

- ^ Wu, Ying et al. (2004) Review of Chemical Processes for the Synthesis of Sodium Borohydride. Millennium Cell Inc.

- .

- ISBN 9780470842898

- )

- OCLC 263409353.

- .

- ISSN 0040-4020.

- ^ da Costa, Jorge C.S.; Pais, Karla C.; Fernandes, Elisa L.; de Oliveira, Pedro S. M.; Mendonça, Jorge S.; de Souza, Marcus V. N.; Peralta, Mônica A.; Vasconcelos, Thatyana R.A. (2006). "Simple reduction of ethyl, isopropyl and benzyl aromatic esters to alcohols using sodium borohydride-methanol system" (PDF). Arkivoc: 128–133. Retrieved 29 August 2006.

- .

- .

- doi:10.1002/aoc.1137.

- ISBN 978-0-471-72091-1

- ISBN 978-0471936237.

- ISBN 9780470132463.

- ISBN 9780470132487.

- PMID 20329388.)

{{cite journal}}: CS1 maint: multiple names: authors list (link - PMID 22873406.

- ^ Masters, Kristin. "How to Prevent and Reverse Foxing in Rare Books". bookstellyouwhy.com. Retrieved 3 April 2018.

- ISBN 978-0-471-19036-3