Phosphoric acid: Difference between revisions

Svencammerer (talk | contribs) |

Extended confirmed users, Pending changes reviewers, Rollbackers 69,705 edits →Purification: tighten up |

||

| Line 128: | Line 128: | ||

== Purification == |

== Purification == |

||

| ⚫ | Phosphoric acids produced from [[phosphate rock]] or thermal processes often requires purification. A common purification methods is liquid-liquid extraction, which involves the separation of phosphoric acids from water and other impurities using organic solvents, such as tributyl phosphate (TBP), methyl isobutyl ketone (MIBK), or n-octanol. Nanofiltration involves the use of a premodified nanofiltration membrane, which is functionalized by a deposit of a high molecular weight polycationic polymer of polyethyleneimines. Nanofiltration has been shown to significantly reduce the concentrations of various impurities, including cadmium, aluminum, iron, and rare earth elements. The laboratory and industrial pilot scale results showed that this process allows the production of food-grade phosphoric acid.<ref>{{cite web |last1=Wet Process Phosphoric Acid Purification |url=https://www.mdpi.com/2297-8739/9/4/100}}</ref> |

||

The production of phosphoric acids from phosphate rocks or thermal processes often results in impure acids that contain undesirable contaminants, such as metals, fluorine, arsenic, and sulfate. Therefore, purification methods are needed to remove these impurities and obtain high-quality phosphoric acids for different applications. |

|||

| ⚫ | Fractional crystallization can achieve highest purities typically used for semiconductor applications. Usually a static crystallizer is used. A static crystallizer uses vertical plates, which are suspended in the molten feed and which are alternatingly cooled and heated by a heat transfer medium. The process begins with the slow cooling of the heat transfer medium below the freezing point of the stagnant melt. This cooling causes a layer of crystals to grow on the plates. Impurities are rejected from the growing crystals and are concentrated in the remaining melt. After the desired fraction has been crystallized, the remaining melt is drained from the crystallizer. The purer crystalline layer remains adhered to the plates. In a subsequent step, the plates are heated again to liquify the crystals and the purified phosphoric acid drained into the product vessel. The crystallizer is filled with feed again and the next cooling cycle is started. [https://www.sulzer.com/-/media/files/products/separation-technology/crystallisation/brochures/fractional_crystallization_e.pdf?sc_lang=en Source: Fractional Crystallization] |

||

=== Liquid-Liquid Extraction === |

|||

One of the common purification methods is liquid-liquid extraction, which involves the separation of phosphoric acids from water and other impurities by using organic solvents, such as tributyl phosphate (TBP), methyl isobutyl ketone (MIBK), or n-octanol. The extraction efficiency depends on the type and concentration of the solvent, the acidity and temperature of the aqueous phase, and the presence of additives or modifiers. The extracted phosphoric acids can then be recovered by stripping with water or another solvent. |

|||

=== Nanofiltration === |

|||

| ⚫ | |||

=== Fractional Crystallization === |

|||

Fractional crystallization is an effective method for the purification of phosphoric acid and can achieve highest purities typically used for semiconductor applications. Usually a static crystallizer is used. A static crystallizer uses vertical plates, which are suspended in the molten feed and which are alternatingly cooled and heated by a heat transfer medium. |

|||

| ⚫ | The process begins with the slow cooling of the heat transfer medium below the freezing point of the stagnant melt. This cooling causes a layer of crystals to grow on the plates. Impurities are rejected from the growing crystals and are concentrated in the remaining melt. After the desired fraction has been crystallized, the remaining melt is drained from the crystallizer. The purer crystalline layer remains adhered to the plates. In a subsequent step, the plates are heated again to liquify the crystals and the purified phosphoric acid drained into the product vessel. The crystallizer is filled with feed again and the next cooling cycle is started. |

||

This process is appreciated for its high flexibility, wide operating range, and the high yield it can achieve, even for viscous products like phosphoric acid. [https://www.sulzer.com/-/media/files/products/separation-technology/crystallisation/brochures/fractional_crystallization_e.pdf?sc_lang=en Source: Fractional Crystallization] |

|||

==Properties== |

==Properties== |

||

Revision as of 19:43, 30 January 2024

| |||

| |||

| Names | |||

|---|---|---|---|

| IUPAC name

Phosphoric acid

| |||

| Other names

Orthophosphoric acid

| |||

| Identifiers | |||

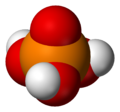

3D model (

JSmol ) |

|||

| ChEBI | |||

| ChEMBL | |||

| ChemSpider | |||

ECHA InfoCard

|

100.028.758 | ||

| EC Number |

| ||

| E number | E338 (antioxidants, ...) | ||

| KEGG | |||

PubChem CID

|

|||

RTECS number

|

| ||

| UNII | |||

| UN number | 1805 | ||

CompTox Dashboard (EPA)

|

|||

| |||

| |||

| Properties | |||

| H3PO4 | |||

| Molar mass | 97.994 g·mol−1 | ||

| Appearance | Colorless solid | ||

| Odor | Odorless | ||

| Density | 1.6845 g/cm3 (25 °C, 85%),[1] 1.834 g/cm3 (solid)[2] | ||

| Melting point | 42.35 °C (108.23 °F; 315.50 K) anhydrous[12] 29.32 °C (84.78 °F; 302.47 K) hemihydrate[13] | ||

| Boiling point | |||

| Solubility | Soluble in ethanol | ||

| log P | −2.15[7] | ||

| Vapor pressure | 0.03 mmHg (20 °C)[8] | ||

Conjugate base

|

Dihydrogen phosphate | ||

| −43.8·10−6 cm3/mol[10] | |||

Refractive index (nD)

|

| ||

| Viscosity | 2.4–9.4 cP (85% aq. soln.) 147 cP (100%) | ||

| Structure | |||

| Monoclinic | |||

| Tetrahedral | |||

| Thermochemistry[14] | |||

Heat capacity (C)

|

145.0 J/(mol⋅K) | ||

Std molar

entropy (S⦵298) |

150.8 J/(mol⋅K) | ||

Std enthalpy of (ΔfH⦵298)formation |

−1271.7 kJ/mol | ||

Gibbs free energy (ΔfG⦵)

|

−1123.6 kJ/mol | ||

| Hazards | |||

| GHS labelling: | |||

[15] [15]

| |||

| Danger | |||

| H290, H314[15] | |||

| P280, P305+P351+P338, P310[15] | |||

| NFPA 704 (fire diamond) | |||

| Flash point | Non-flammable | ||

| Lethal dose or concentration (LD, LC): | |||

LD50 (median dose)

|

1530 mg/kg (rat, oral)[16] | ||

| NIOSH (US health exposure limits): | |||

PEL (Permissible)

|

TWA 1 mg/m3[8] | ||

REL (Recommended)

|

TWA 1 mg/m3 ST 3 mg/m3[8] | ||

IDLH (Immediate danger) |

1000 mg/m3[8] | ||

| Safety data sheet (SDS) | ICSC 1008 | ||

| Related compounds | |||

Related

oxoacids |

| ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |||

Phosphoric acid (orthophosphoric acid, monophosphoric acid or phosphoric(V) acid) is a colorless, odorless phosphorus-containing solid, and inorganic compound with the chemical formula H3PO4. It is commonly encountered as an 85% aqueous solution, which is a colourless, odourless, and non-volatile syrupy liquid. It is a major industrial chemical, being a component of many fertilizers.

The compound is an

The name "orthophosphoric acid" can be used to distinguish this specific acid from other "

Production

Phosphoric acid is produced industrially by one of two routes, wet processes and dry.[18][19][20]

Wet process

In the wet process, a phosphate-containing mineral such as calcium hydroxyapatite and fluorapatite are treated with sulfuric acid.[21]

- Ca5(PO4)3OH + 5 H2SO4 → 3 H3PO4 + 5 CaSO4+ H2O

- Ca5(PO4)3F + 5 H2SO4 → 3 H3PO4 + 5 CaSO4+ HF

Calcium sulfate (gypsum, CaSO4) is a by-product, which is removed as phosphogypsum. The hydrogen fluoride (HF) gas is streamed into a wet (water) scrubber producing hydrofluoric acid. In both cases the phosphoric acid solution usually contains 23–33% P2O5 (32–46% H3PO4). It may be concentrated to produce commercial- or merchant-grade phosphoric acid, which contains about 54–62% P2O5 (75–85% H3PO4). Further removal of water yields superphosphoric acid with a P2O5 concentration above 70% (corresponding to nearly 100% H3PO4). The phosphoric acid from both processes may be further purified by removing compounds of arsenic and other potentially toxic impurities.

Dry process

To produce food-grade phosphoric acid, phosphate ore is first reduced with coke in an electric arc furnace, to give elemental phosphorus. This process is also known as the thermal process or the electric furnace process. Silica is also added, resulting in the production of calcium silicate slag. Elemental phosphorus is distilled out of the furnace and burned with air to produce high-purity phosphorus pentoxide, which is dissolved in water to make phosphoric acid.[22] The thermal process produces phosphoric acid with a very high concentration of P2O5 (about 85%) and a low level of impurities.

However, this process is more expensive and energy-intensive than the wet process, which produces phosphoric acid with a lower concentration of P2O5 (about 26-52%) and a higher level of impurities. The wet process is the most common method of producing phosphoric acid for fertilizer use. Source: Phosphoric Acid and Phosphatic Fertilizers: A profile

Purification

Phosphoric acids produced from

Fractional crystallization can achieve highest purities typically used for semiconductor applications. Usually a static crystallizer is used. A static crystallizer uses vertical plates, which are suspended in the molten feed and which are alternatingly cooled and heated by a heat transfer medium. The process begins with the slow cooling of the heat transfer medium below the freezing point of the stagnant melt. This cooling causes a layer of crystals to grow on the plates. Impurities are rejected from the growing crystals and are concentrated in the remaining melt. After the desired fraction has been crystallized, the remaining melt is drained from the crystallizer. The purer crystalline layer remains adhered to the plates. In a subsequent step, the plates are heated again to liquify the crystals and the purified phosphoric acid drained into the product vessel. The crystallizer is filled with feed again and the next cooling cycle is started. Source: Fractional Crystallization

Properties

Acidic properties

In aqueous solution phosphoric acid behaves as a triprotic acid.

- H3PO4 ⇌ H2PO−4 + H+, pKa1 = 2.14

- H2PO−4 ⇌ HPO2−4 + H+, pKa2 = 7.20

- HPO2−4 ⇌ PO3−4 + H+, pKa3 = 12.37

The difference between successive

Aqueous solutions

Aqueous solutions up to 62.5% H3PO4 are

Self condensation

Phosphoric acid is commercially available as aqueous solutions of various concentrations, not usually exceeding 85%. If concentrated further it undergoes slow self-condensation, forming an equilibrium with pyrophosphoric acid:

- 2 H3PO4 ⇌ H2O + H4P2O7

Even at 90% concentration the amount of pyrophosphoric acid present is negligible, but beyond 95% it starts to increase, reaching 15% at what would have otherwise been 100% orthophosphoric acid.[26]

As the concentration is increased

Uses

The dominant use of phosphoric acid is for fertilizers, consuming approximately 90% of production.[28]

| Application | Demand (2006) in thousands of tons | Main phosphate derivatives |

|---|---|---|

| Soaps and detergents | 1836 | STPP |

| Food industry | 309 | STPP (Na5P3O10), SHMP, TSP, SAPP, SAlP, MCP, DSP (Na2HPO4), H3PO4 |

| Water treatment | 164 | SHMP, STPP, TSPP, MSP (NaH2PO4), DSP |

| Toothpastes | 68 | DCP (CaHPO4), IMP, SMFP |

| Other applications | 287 | STPP (Na3P3O9), TCP, APP, DAP, zinc phosphate (Zn3(PO4)2), aluminium phosphate (AlPO4), H3PO4 |

Food-grade phosphoric acid (additive E338[29]) is used to acidify foods and beverages such as various colas and jams, providing a tangy or sour taste. The phosphoric acid also serves as a preservative.[30] Soft drinks containing phosphoric acid, which would include Coca-Cola, are sometimes called phosphate sodas or phosphates. Phosphoric acid in soft drinks has the potential to cause dental erosion.[31] Phosphoric acid also has the potential to contribute to the formation of kidney stones, especially in those who have had kidney stones previously.[32]

Specific applications of phosphoric acid include:

- in anti-rust treatment by phosphate conversion coating or passivation

- to prevent Parkerizationprocess

- as an external standard for phosphorus-31 nuclear magnetic resonance

- in phosphoric acid fuel cells

- in activated carbon production[33]

- in compound semiconductor processing, to etch Indium gallium arsenide selectively with respect to indium phosphide[34]

- in microfabrication to etch silicon nitride selectively with respect to silicon dioxide[35]

- in microfabrication to etch aluminium

- as a pH adjuster in cosmetics and skin-care products[36]

- as a sanitizing agent in the dairy, food, and brewing industries[37]

Phosphoric acid may also be used for chemical polishing (etching) of metals like aluminium or for passivation of steel products in a process called phosphatization.[38]

Safety

Phosphoric acid is not a

A link has been shown between long-term regular cola intake and osteoporosis in later middle age in women (but not men).[40]

See also

- Phosphate fertilizers, such as ammonium phosphate fertilizers

References

- .

- ^ "CAMEO Chemicals Datasheet – Phosphoric Acid". Archived from the original on 15 August 2019. Retrieved 15 August 2019.

- ^ "Phosphoric acid". www.chemspider.com. Archived from the original on 12 March 2020. Retrieved 3 March 2020.

- .

- ^ Seidell, Atherton; Linke, William F. (1952). Solubilities of Inorganic and Organic Compounds. Van Nostrand. Archived from the original on 11 March 2020. Retrieved 2 June 2014.

- ^ Haynes, p. 4.80

- ^ "phosphoric acid_msds". Archived from the original on 4 July 2017. Retrieved 2 May 2018.

- ^ a b c d NIOSH Pocket Guide to Chemical Hazards. "#0506". National Institute for Occupational Safety and Health (NIOSH).

- ^ Haynes, p. 5.92

- ^ Haynes, p. 4.134

- .

- ^ .

- ^ ISSN 0019-7866.

- ^ Haynes, p. 5.13

- ^ a b c Sigma-Aldrich Co., Phosphoric acid.

- ^ "Phosphoric acid". Immediately Dangerous to Life or Health Concentrations (IDLH). National Institute for Occupational Safety and Health (NIOSH).

- PMID 2434996.

- ISBN 978-0824717124.

- ISBN 9781439895108.

- PMID 33210686.

- ISBN 978-0-08-037941-8.

- PMID 32607432.

- ^ Wet Process Phosphoric Acid Purification. https://www.mdpi.com/2297-8739/9/4/100.

{{cite web}}: Missing or empty|title=(help) - .

- ^ "Purified Phosphoric Acid H3PO4 Technical Information Bulletin" (PDF). PotashCorp. Retrieved 11 February 2023.

- ISBN 978-3-319-17081-7, retrieved 12 February 2023

- .

- ISBN 978-3527306732.

- ^ "Current EU approved additives and their E Numbers". Foods Standards Agency. 14 March 2012. Archived from the original on 21 August 2013. Retrieved 22 July 2012.

- ^ "Why is phosphoric acid used in some Coca‑Cola drinks?| Frequently Asked Questions | Coca-Cola GB". www.coca-cola.co.uk. Archived from the original on 2 August 2021. Retrieved 31 August 2021.

- PMID 12481178.

- S2CID 3058172.

- .

- ^ Wet chemical etching. Archived 25 September 2012 at the Wayback Machine umd.edu.

- ISBN 978-0-9616721-6-4.

- ^ "Ingredient dictionary: P". Cosmetic ingredient dictionary. Paula's Choice. Archived from the original on 18 January 2008. Retrieved 16 November 2007.

- ^ "Star San" (PDF). Five Star Chemicals. Archived (PDF) from the original on 8 February 2016. Retrieved 17 August 2015.

- ^ "Phosphates - Metal Finishing" (PDF). Phospates for Americas. February 2021.

- ^ "Phosphoric Acid, 85 wt.% SDS". Sigma-Aldrich. 5 May 2016. Archived from the original on 18 January 2017. Retrieved 16 January 2017.

- PMID 17023723.

Cited sources

- Haynes, William M., ed. (2011). ISBN 978-1439855119.