Molybdenum

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Molybdenum | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pronunciation | /məˈlɪbdənəm/ | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Appearance | gray metallic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard atomic weight Ar°(Mo) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Molybdenum in the periodic table | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

kJ/mol | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Heat of vaporization | 598 kJ/mol | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Molar heat capacity | 24.06 J/(mol·K) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vapor pressure

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Atomic properties | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Discovery | Carl Wilhelm Scheele (1778) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| First isolation | Peter Jacob Hjelm (1781) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Isotopes of molybdenum | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Molybdenum is a

Molybdenum does not occur naturally as a

Most molybdenum compounds have low

.Characteristics

Physical properties

In its pure form, molybdenum is a silvery-grey metal with a

Chemical properties

Molybdenum is a transition metal with an electronegativity of 2.16 on the Pauling scale. It does not visibly react with oxygen or water at room temperature, but is attacked by halogens and hydrogen peroxide. Weak oxidation of molybdenum starts at 300 °C (572 °F); bulk oxidation occurs at temperatures above 600 °C, resulting in molybdenum trioxide. Like many heavier transition metals, molybdenum shows little inclination to form a cation in aqueous solution, although the Mo3+ cation is known to form under carefully controlled conditions.[18]

Gaseous molybdenum consists of the diatomic species Mo2. That molecule is a singlet, with two unpaired electrons in bonding orbitals, in addition to 5 conventional bonds. The result is a sextuple bond.[19][20]

Isotopes

There are 39 known

Molybdenum-98 is the most

The most common isotopic molybdenum application involves

Compounds

Molybdenum forms chemical compounds in oxidation states −4 and from −2 to +6. Higher oxidation states are more relevant to its terrestrial occurrence and its biological roles, mid-level oxidation states are often associated with

| Oxidation state |

Example[24][25] |

|---|---|

| −4 | Na 4[Mo(CO) 4] |

| −2 | [Mo(CO) 5]2− [26] |

| −1 | Na 2[Mo 2(CO) 10] |

| 0 | Mo(CO) 6 |

| +1 | C

5H 5Mo(CO) 3 |

| +2 | MoCl 2 |

| +3 | MoBr 3 |

| +4 | MoS 2 |

| +5 | MoCl 5 |

| +6 | MoF

6 |

From the perspective of commerce, the most important compounds are molybdenum disulfide (MoS

2) and molybdenum trioxide (MoO

3). The black disulfide is the main mineral. It is roasted in air to give the trioxide:[23]

- 2 MoS

2 + 7 O

2 → 2 MoO

3 + 4 SO

2

The trioxide, which is volatile at high temperatures, is the precursor to virtually all other Mo compounds as well as alloys. Molybdenum has several oxidation states, the most stable being +4 and +6 (bolded in the table at left).

Molybdenum(VI) oxide is soluble in strong

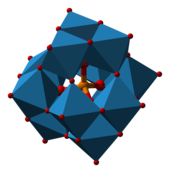

- Molybdenum(II) chloride MoCl2, which exists as the hexamer Mo6Cl12 and the related dianion [Mo6Cl14]2-.

- Molybdenum(III) chloride MoCl3, a dark red solid, which converts to the anion trianionic complex [MoCl6]3-.

- Molybdenum(IV) chloride MoCl4, a black solid, which adopts a polymeric structure.

- Molybdenum(V) chloride MoCl5 dark green solid, which adopts a dimeric structure.

- Molybdenum(VI) chloride MoCl6 is a black solid, which is monomeric and slowly decomposes to MoCl5 and Cl2 at room temperature.[29]

Like chromium and some other transition metals, molybdenum forms quadruple bonds, such as in Mo2(CH3COO)4 and [Mo2Cl8]4−.[23][30] The Lewis acid properties of the butyrate and perfluorobutyrate dimers, Mo2(O2CR)4 and Rh2(O2CR) 4, have been reported.[31]

The oxidation state 0 and lower are possible with carbon monoxide as ligand, such as in molybdenum hexacarbonyl, Mo(CO)6.[23][25]

History

Although (reportedly) molybdenum was deliberately alloyed with steel in one 14th-century Japanese sword (mfd. c. 1330), that art was never employed widely and was later lost.[34][35] In the West in 1754, Bengt Andersson Qvist examined a sample of molybdenite and determined that it did not contain lead and thus was not galena.[36]

By 1778 Swedish chemist Carl Wilhelm Scheele stated firmly that molybdena was (indeed) neither galena nor graphite.[37][38] Instead, Scheele correctly proposed that molybdena was an ore of a distinct new element, named molybdenum for the mineral in which it resided, and from which it might be isolated. Peter Jacob Hjelm successfully isolated molybdenum using carbon and linseed oil in 1781.[17][39]

For the next century, molybdenum had no industrial use. It was relatively scarce, the pure metal was difficult to extract, and the necessary techniques of metallurgy were immature.

During

Occurrence and production

Molybdenum is the 54th most abundant element in the Earth's crust with an average of 1.5 parts per million and the 25th most abundant element in its oceans, with an average of 10 parts per billion; it is the 42nd most abundant element in the Universe.[17][48] The Soviet Luna 24 mission discovered a molybdenum-bearing grain (1 × 0.6 µm) in a pyroxene fragment taken from Mare Crisium on the Moon.[49] The comparative rarity of molybdenum in the Earth's crust is offset by its concentration in a number of water-insoluble ores, often combined with sulfur in the same way as copper, with which it is often found. Though molybdenum is found in such minerals as wulfenite (PbMoO4) and powellite (CaMoO4), the main commercial source is molybdenite (MoS2). Molybdenum is mined as a principal ore and is also recovered as a byproduct of copper and tungsten mining.[10]

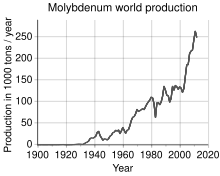

The world's production of molybdenum was 250,000 tonnes in 2011, the largest producers being China (94,000 t), the United States (64,000 t), Chile (38,000 t), Peru (18,000 t) and Mexico (12,000 t). The total reserves are estimated at 10 million tonnes, and are mostly concentrated in China (4.3 Mt), the US (2.7 Mt) and Chile (1.2 Mt). By continent, 93% of world molybdenum production is about evenly shared between North America, South America (mainly in Chile), and China. Europe and the rest of Asia (mostly Armenia, Russia, Iran and Mongolia) produce the remainder.[50]

In molybdenite processing, the ore is first roasted in air at a temperature of 700 °C (1,292 °F). The process gives gaseous sulfur dioxide and the molybdenum(VI) oxide:[23]

The resulting oxide is then usually extracted with aqueous ammonia to give ammonium molybdate:

Copper, an impurity in molybdenite, is separated at this stage by treatment with hydrogen sulfide.[23] Ammonium molybdate converts to ammonium dimolybdate, which is isolated as a solid. Heating this solid gives molybdenum trioxide:[51]

Crude trioxide can be further purified by sublimation at 1,100 °C (2,010 °F).

Metallic molybdenum is produced by reduction of the oxide with hydrogen:

The molybdenum for steel production is reduced by the aluminothermic reaction with addition of iron to produce ferromolybdenum. A common form of ferromolybdenum contains 60% molybdenum.[23][52]

Molybdenum had a value of approximately $30,000 per tonne as of August 2009. It maintained a price at or near $10,000 per tonne from 1997 through 2003, and reached a peak of $103,000 per tonne in June 2005.[53] In 2008, the London Metal Exchange announced that molybdenum would be traded as a commodity.[54]

Mining

The

Applications

Alloys

About 86% of molybdenum produced is used in metallurgy, with the rest used in chemical applications. The estimated global use is structural steel 35%, stainless steel 25%, chemicals 14%, tool & high-speed steels 9%, cast iron 6%, molybdenum elemental metal 6%, and superalloys 5%.[57]

Molybdenum can withstand extreme temperatures without significantly expanding or softening, making it useful in environments of intense heat, including military armor, aircraft parts, electrical contacts, industrial motors, and supports for filaments in

Most high-strength steel alloys (for example, 41xx steels) contain 0.25% to 8% molybdenum.[10] Even in these small portions, more than 43,000 tonnes of molybdenum are used each year in stainless steels, tool steels, cast irons, and high-temperature superalloys.[48]

Molybdenum is also used in steel alloys for its high

Because of its lower density and more stable price, molybdenum is sometimes used in place of tungsten.[48] An example is the 'M' series of high-speed steels such as M2, M4 and M42 as substitution for the 'T' steel series, which contain tungsten. Molybdenum can also be used as a flame-resistant coating for other metals. Although its melting point is 2,623 °C (4,753 °F), molybdenum rapidly oxidizes at temperatures above 760 °C (1,400 °F) making it better-suited for use in vacuum environments.[58]

TZM (Mo (~99%), Ti (~0.5%), Zr (~0.08%) and some C) is a corrosion-resisting molybdenum superalloy that resists molten fluoride salts at temperatures above 1,300 °C (2,370 °F). It has about twice the strength of pure Mo, and is more ductile and more weldable, yet in tests it resisted corrosion of a standard eutectic salt (

Other molybdenum-based alloys that do not contain iron have only limited applications. For example, because of its resistance to molten zinc, both pure molybdenum and molybdenum-tungsten alloys (70%/30%) are used for piping, stirrers and pump impellers that come into contact with molten zinc.[62]

Other applications as a pure element

- Molybdenum powder is used as a fertilizer for some plants, such as cauliflower.[48]

- Elemental molybdenum is used in NO, NO2, NOx analyzers in power plants for pollution controls. At 350 °C (662 °F), the element acts as a catalyst for NO2/NOx to form NO molecules for detection by infrared light.[63]

- Molybdenum anodes replace tungsten in certain low voltage X-ray sources for specialized uses such as mammography.[64]

- The radioactive isotope molybdenum-99 is used to generate technetium-99m, used for medical imaging[65] The isotope is handled and stored as the molybdate.[66]

Compounds

- Molybdenum disulfide (MoS2) is used as a solid lubricant and a high-pressure high-temperature (HPHT) anti-wear agent. It forms strong films on metallic surfaces and is a common additive to HPHT greases — in the event of a catastrophic grease failure, a thin layer of molybdenum prevents contact of the lubricated parts.[67]

- When combined with small amounts of cobalt, MoS2 is also used as a catalyst in the hydrodesulfurization (HDS) of petroleum. In the presence of hydrogen, this catalyst facilitates the removal of nitrogen and especially sulfur from the feedstock, which otherwise would poison downstream catalysts. HDS is one of the largest scale applications of catalysis in industry.[68]

- Molybdenum oxides are important catalysts for selective oxidation of organic compounds. The production of the commodity chemicals acrylonitrile and formaldehyde relies on MoOx-based catalysts.[51]

- Molybdenum disilicide (MoSi2) is an electrically conducting ceramic with primary use in heating elements operating at temperatures above 1500 °C in air.[69]

- Molybdenum trioxide (MoO3) is used as an adhesive between enamels and metals.[37]

- Lead molybdate (wulfenite) co-precipitated with lead chromate and lead sulfate is a bright-orange pigment used with ceramics and plastics.[70]

- The molybdenum-based mixed oxides are versatile catalysts in the chemical industry. Some examples are the catalysts for the oxidation of carbon monoxide, propylene to acrolein and acrylic acid, the ammoxidation of propylene to acrylonitrile.[71][72]

- Molybdenum carbides, nitride and phosphides can be used for hydrotreatment of rapeseed oil.[73]

- Ammonium heptamolybdate is used in biological staining.[citation needed]

- Molybdenum coated soda lime glass is used in CIGS (CIGS solar cells.

- histochemistry.[74]

Biological role

Mo-containing enzymes

Molybdenum is an essential element in most organisms; a 2008 research paper speculated that a scarcity of molybdenum in the Earth's early oceans may have strongly influenced the evolution of eukaryotic life (which includes all plants and animals).[75]

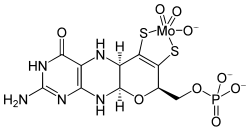

At least 50 molybdenum-containing enzymes have been identified, mostly in bacteria.[76][77] Those enzymes include aldehyde oxidase, sulfite oxidase and xanthine oxidase.[17] With one exception, Mo in proteins is bound by molybdopterin to give the molybdenum cofactor. The only known exception is nitrogenase, which uses the FeMoco cofactor, which has the formula Fe7MoS9C.[78]

In terms of function, molybdoenzymes catalyze the oxidation and sometimes reduction of certain small molecules in the process of regulating

Mo is a component in most nitrogenases. Among molybdoenzymes, nitrogenases are unique in lacking the molybdopterin.[81][82] Nitrogenases catalyze the production of ammonia from atmospheric nitrogen:

The biosynthesis of the FeMoco active site is highly complex.[83]

Molybdate is transported in the body as MoO42−.[80]

Human metabolism and deficiency

Molybdenum is an essential trace

Acute toxicity has not been seen in humans, and the toxicity depends strongly on the chemical state. Studies on rats show a median lethal dose (LD50) as low as 180 mg/kg for some Mo compounds.[90] Although human toxicity data is unavailable, animal studies have shown that chronic ingestion of more than 10 mg/day of molybdenum can cause diarrhea, growth retardation, infertility, low birth weight, and gout; it can also affect the lungs, kidneys, and liver.[91][92] Sodium tungstate is a competitive inhibitor of molybdenum. Dietary tungsten reduces the concentration of molybdenum in tissues.[48]

Low soil concentration of molybdenum in a geographical band from northern China to Iran results in a general dietary

Molybdenum deficiency has also been reported as a consequence of non-molybdenum supplemented

A congenital

Excretion

Most molybdenum is excreted from the human body as molybdate in the urine. Furthermore, urinary excretion of molybdenum increases as dietary molybdenum intake increases. Small amounts of molybdenum are excreted from the body in the feces by way of the bile; small amounts also can be lost in sweat and in hair.[100][101]

Excess and copper antagonism

High levels of molybdenum can interfere with the body's uptake of copper, producing copper deficiency. Molybdenum prevents plasma proteins from binding to copper, and it also increases the amount of copper that is excreted in urine. Ruminants that consume high levels of molybdenum suffer from diarrhea, stunted growth, anemia, and achromotrichia (loss of fur pigment). These symptoms can be alleviated by copper supplements, either dietary and injection.[102] The effective copper deficiency can be aggravated by excess sulfur.[48][103]

Copper reduction or deficiency can also be deliberately induced for therapeutic purposes by the compound

In some grazing livestock, most strongly in cattle, molybdenum excess in the soil of pasturage can produce scours (diarrhea) if the pH of the soil is neutral to alkaline; see teartness.

Dietary recommendations

In 2000, the then U.S. Institute of Medicine (now the

An AI of 2 micrograms (μg) of molybdenum per day was established for infants up to 6 months of age, and 3 μg/day from 7 to 12 months of age, both for males and females. For older children and adults, the following daily RDAs have been established for molybdenum: 17 μg from 1 to 3 years of age, 22 μg from 4 to 8 years, 34 μg from 9 to 13 years, 43 μg from 14 to 18 years, and 45 μg for persons 19 years old and older. All these RDAs are valid for both sexes. Pregnant or lactating females from 14 to 50 years of age have a higher daily RDA of 50 μg of molybdenum.

As for safety, the NAM sets

The European Food Safety Authority (EFSA) refers to the collective set of information as Dietary Reference Values, with Population Reference Intake (PRI) instead of RDA, and Average Requirement instead of EAR. AI and UL defined the same as in United States. For women and men ages 15 and older the AI is set at 65 μg/day. Pregnant and lactating women have the same AI. For children aged 1–14 years, the AIs increase with age from 15 to 45 μg/day. The adult AIs are higher than the U.S. RDAs,[108] but on the other hand, the European Food Safety Authority reviewed the same safety question and set its UL at 600 μg/day, which is much lower than the U.S. value.[109]

Labeling

For U.S. food and dietary supplement labeling purposes, the amount in a serving is expressed as a percent of Daily Value (%DV). For molybdenum labeling purposes 100% of the Daily Value was 75 μg, but as of May 27, 2016 it was revised to 45 μg.[110][111] A table of the old and new adult daily values is provided at Reference Daily Intake.

Food sources

Average daily intake varies between 120 and 240 μg/day, which is higher than dietary recommendations.[91] Pork, lamb, and beef liver each have approximately 1.5 parts per million of molybdenum. Other significant dietary sources include green beans, eggs, sunflower seeds, wheat flour, lentils, cucumbers, and cereal grain.[17]

Precautions

Molybdenum dusts and fumes, generated by mining or metalworking, can be toxic, especially if ingested (including dust trapped in the

See also

References

- ^ "Standard Atomic Weights: Molybdenum". CIAAW. 2013.

- ISSN 1365-3075.

- ^ ISBN 978-1-62708-155-9.

- ^ "Molybdenum: molybdenum(I) fluoride compound data". OpenMOPAC.net. Retrieved 2007-12-10.

- PlanseeSeminar.

- ISBN 0-8493-0486-5.

- ISBN 0-8493-0464-4.

- ^ .

- ^ PMID 34611245.

- ^ ISBN 978-0-8493-0474-3.

- ^ "It's Elemental – The Element Molybdenum". Science Education at Jefferson Lab. Archived from the original on 2018-07-04. Retrieved 2018-07-03.

- PMID 25549604.

- PMID 31441651.

- PMID 32239579.

- S2CID 98084907. Archived from the original(PDF) on 2012-03-11. Retrieved 2012-02-13.

- ^ Meija, Juris; et al. (2013). "Current Table of Standard Atomic Weights in Alphabetical Order: Standard Atomic weights of the elements". Commission on Isotopic Abundances and Atomic Weights. Archived from the original on 2014-04-29.

- ^ ISBN 978-0-19-850341-5.

- ISBN 978-0-582-44278-8.

- PMID 18004851.

- PMID 17225237.

- ^ Armstrong, John T. (2003). "Technetium". Chemical & Engineering News. Archived from the original on 2008-10-06. Retrieved 2009-07-07.

- ^ Wolterbeek, Hubert Theodoor; Bode, Peter "A process for the production of no-carrier added 99Mo". European Patent EP2301041 (A1) ― 2011-03-30. Retrieved on 2012-06-27.

- ^ ISBN 978-3-11-007511-3.

- ISBN 978-3-663-14240-9.

- ^ ISBN 978-0-387-09848-7.

- .

- .

- ISBN 978-0-8247-8433-1.

- PMID 23172658.

- ISBN 978-1118744994.

- ISSN 0020-1669.

- ISBN 978-0-444-50032-8.

- ^ Melchert, Craig. "Greek mólybdos as a Loanword from Lydian" (PDF). University of North Carolina at Chapel Hill. Archived (PDF) from the original on 2013-12-31. Retrieved 2011-04-23.

- ^ "Molybdenum History". International Molybdenum Association. Archived from the original on 2013-07-22.

- ^ Accidental use of molybdenum in old sword led to new alloy. American Iron and Steel Institute. 1948.

- ^ Van der Krogt, Peter (2006-01-10). "Molybdenum". Elementymology & Elements Multidict. Archived from the original on 2010-01-23. Retrieved 2007-05-20.

- ^ a b Gagnon, Steve. "Molybdenum". Jefferson Science Associates, LLC. Archived from the original on 2007-04-26. Retrieved 2007-05-06.

- ^ Scheele, C. W. K. (1779). "Versuche mit Wasserbley; Molybdaena". Svenska Vetensk. Academ. Handlingar. 40: 238.

- ^ Hjelm, P. J. (1788). "Versuche mit Molybdäna, und Reduction der selben Erde". Svenska Vetensk. Academ. Handlingar. 49: 268.

- ^ Hoyt, Samuel Leslie (1921). Metallography. Vol. 2. McGraw-Hill.

- ^ Krupp, Alfred; Wildberger, Andreas (1888). The metallic alloys: A practical guide for the manufacture of all kinds of alloys, amalgams, and solders, used by metal-workers ... with an appendix on the coloring of alloys. H.C. Baird & Co. p. 60.

- ISBN 978-0-8493-4758-0.

- ISBN 978-0521522373. Archivedfrom the original on 2014-07-09. Retrieved 2016-04-07.

- ^ Vokes, Frank Marcus (1963). Molybdenum deposits of Canada. p. 3.

- ^ Chemical properties of molibdenum – Health effects of molybdenum – Environmental effects of molybdenum Archived 2016-01-20 at the Wayback Machine. lenntech.com

- ISBN 978-0-316-05163-7.

- ^ Millholland, Ray (August 1941). "Battle of the Billions: American industry mobilizes machines, materials, and men for a job as big as digging 40 Panama Canals in one year". Popular Science: 61. Archived from the original on 2014-07-09. Retrieved 2016-04-07.

- ^ ISBN 978-0-471-61525-5.

- ^ Jambor, J.L.; et al. (2002). "New mineral names" (PDF). American Mineralogist. 87: 181. Archived (PDF) from the original on 2007-07-10. Retrieved 2007-04-09.

- ^ a b "Molybdenum Statistics and Information". U.S. Geological Survey. 2007-05-10. Archived from the original on 2007-05-19. Retrieved 2007-05-10.

- ^ S2CID 98762721.

- ISBN 978-0-8493-4758-0.

- ^ "Dynamic Prices and Charts for Molybdenum". InfoMine Inc. 2007. Archived from the original on 2009-10-08. Retrieved 2007-05-07.

- ^ "LME to launch minor metals contracts in H2 2009". London Metal Exchange. 2008-09-04. Archived from the original on 2012-07-22. Retrieved 2009-07-28.

- .

- doi:10.1086/232443.

- ^ "Molybdenum". Industry usage. London Metal Exchange. Archived from the original on 2012-03-10.

- ^ a b "Molybdenum". AZoM.com Pty. Limited. 2007. Archived from the original on 2011-06-14. Retrieved 2007-05-06.

- ^ (2023) Stainless Steel Grades and Properties. International Molybdenum Association. https://www.imoa.info/molybdenum-uses/molybdenum-grade-stainless-steels/steel-grades.php?m=1683978651&

- ISBN 978-0803102033.

- ^ "Compatibility of Molybdenum-Base Alloy TZM, with LiF-BeF2-ThF4-UF4". Oak Ridge National Laboratory Report. December 1969. Archived from the original on 2011-07-10. Retrieved 2010-09-02.

- ISBN 978-0-87263-351-3.

- S2CID 20441999.

- ^ Lancaster, Jack L. "Ch. 4: Physical determinants of contrast" (PDF). Physics of Medical X-Ray Imaging. University of Texas Health Science Center. Archived from the original (PDF) on 2015-10-10.

- ISBN 1-57912-814-9.

- PMID 4894500.

- hdl:2027.42/33266.

- ^ Topsøe, H.; Clausen, B. S.; Massoth, F. E. (1996). Hydrotreating Catalysis, Science and Technology. Berlin: Springer-Verlag.

- ISBN 978-0-471-49748-6.

- ^ International Molybdenum Association Archived 2008-03-09 at the Wayback Machine. imoa.info.

- ^ Fierro, J. G. L., ed. (2006). Metal Oxides, Chemistry and Applications. CRC Press. pp. 414–455.

- ^ Centi, G.; Cavani, F.; Trifiro, F. (2001). Selective Oxidation by Heterogeneous Catalysis. Kluwer Academic/Plenum Publishers. pp. 363–384.

- S2CID 208758175.

- .

- S2CID 205212619.

- PMID 14871153.

- PMID 16784786.

- PMID 24467397.

- (PDF) from the original on 2017-08-10. Retrieved 2017-10-25.

- ^ a b Mitchell, Phillip C. H. (2003). "Overview of Environment Database". International Molybdenum Association. Archived from the original on 2007-10-18. Retrieved 2007-05-05.

- ISSN 1868-0402

- ^

Chi Chung, Lee; Markus W., Ribbe; Yilin, Hu (2014). "Biochemistry of Methyl-Coenzyme M Reductase: The Nickel Metalloenzyme that Catalyzes the Final Step in Synthesis and the First Step in Anaerobic Oxidation of the Greenhouse Gas Methane". In Peter M.H. Kroneck; Martha E. Sosa Torres (eds.). The Metal-Driven Biogeochemistry of Gaseous Compounds in the Environment. Metal Ions in Life Sciences. Vol. 14. Springer. pp. 147–174. PMID 25416393.

- PMID 18697949.

- PMID 24470099.

- S2CID 205487570.

- ^ Blaylock Wellness Report, February 2010, page 3.

- PMID 4519654.

- ISBN 978-0-12-352651-9.

- S2CID 72386871.

- ^ a b "Risk Assessment Information System: Toxicity Summary for Molybdenum". Oak Ridge National Laboratory. Archived from the original on September 19, 2007. Retrieved 2008-04-23.

- ^ S2CID 10114173.

- PMID 10382558.

- (PDF) from the original on 2015-11-23. Retrieved 2011-12-30.

- PMID 18588371. Archived from the original(PDF) on 2011-07-19. Retrieved 2009-03-23.

- ^ Zheng, Liu; et al. (1982). "Geographical distribution of trace elements-deficient soils in China". Acta Ped. Sin. 19: 209–223. Archived from the original on 2021-02-05. Retrieved 2020-07-25.

- (PDF) from the original on 2016-09-17. Retrieved 2016-07-01.

- PMID 6426561.

- PMID 18411266.

- PMID 10746556.)

{{cite journal}}: CS1 maint: DOI inactive as of February 2024 (link - ISBN 978-1-337-51421-7.

- PMID 7572711.

- PMID 4617883.

- ^ Hauer, Gerald Copper deficiency in cattle Archived 2011-09-10 at the Wayback Machine. Bison Producers of Alberta. Accessed Dec. 16, 2010.

- PMID 12752430.

- PMID 12633149.

- PMID 10656425.

- S2CID 44243659.

- ^ "Overview on Dietary Reference Values for the EU population as derived by the EFSA Panel on Dietetic Products, Nutrition and Allergies" (PDF). 2017. Archived from the original (PDF) on 2017-08-28. Retrieved 2017-09-10.

- ^ Tolerable Upper Intake Levels For Vitamins And Minerals (PDF), European Food Safety Authority, 2006, archived from the original (PDF) on 2016-03-16, retrieved 2017-09-10

- ^ "Federal Register May 27, 2016 Food Labeling: Revision of the Nutrition and Supplement Facts Labels. FR page 33982" (PDF). Archived (PDF) from the original on August 8, 2016. Retrieved September 10, 2017.

- ^ "Daily Value Reference of the Dietary Supplement Label Database (DSLD)". Dietary Supplement Label Database (DSLD). Archived from the original on 7 April 2020. Retrieved 16 May 2020.

- ^ "Material Safety Data Sheet – Molybdenum". The REMBAR Company, Inc. 2000-09-19. Archived from the original on March 23, 2007. Retrieved 2007-05-13.

- ^ "Material Safety Data Sheet – Molybdenum Powder". CERAC, Inc. 1994-02-23. Archived from the original on 2011-07-08. Retrieved 2007-10-19.

- ^ "NIOSH Documentation for IDLHs Molybdenum". National Institute for Occupational Safety and Health. 1996-08-16. Archived from the original on 2007-08-07. Retrieved 2007-05-31.

- ^ "CDC – NIOSH Pocket Guide to Chemical Hazards – Molybdenum". www.cdc.gov. Archived from the original on 2015-11-20. Retrieved 2015-11-20.

Bibliography

- Lettera di Giulio Candida al signor Vincenzo Petagna – Sulla formazione del molibdeno. Naples: Giuseppe Maria Porcelli. 1785.

External links

- Molybdenum at The Periodic Table of Videos(University of Nottingham)

- Mineral & Exploration – Map of World Molybdenum Producers 2009

- "Mining A Mountain" Popular Mechanics, July 1935 pp. 63–64

- Site for global molybdenum info

- CDC – NIOSH Pocket Guide to Chemical Hazards