Metallurgy

Metallurgy is a domain of

Metallurgy encompasses both the science and the technology of metals, including the production of metals and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft of metalworking. Metalworking relies on metallurgy in a similar manner to how medicine relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist.

The science of metallurgy is further subdivided into two broad categories: chemical metallurgy and physical metallurgy. Chemical metallurgy is chiefly concerned with the reduction and oxidation of metals, and the chemical performance of metals. Subjects of study in chemical metallurgy include mineral processing, the extraction of metals, thermodynamics, electrochemistry, and chemical degradation (corrosion).[1] In contrast, physical metallurgy focuses on the mechanical properties of metals, the physical properties of metals, and the physical performance of metals. Topics studied in physical metallurgy include crystallography, material characterization, mechanical metallurgy, phase transformations, and failure mechanisms.[2]

Historically, metallurgy has predominately focused on the production of metals. Metal production begins with the processing of

Ferrous metallurgy involves processes and alloys based on iron, while non-ferrous metallurgy involves processes and alloys based on other metals. The production of ferrous metals accounts for 95% of world metal production.[3]

Modern metallurgists work in both emerging and traditional areas as part of an interdisciplinary team alongside material scientists and other engineers. Some traditional areas include mineral processing, metal production, heat treatment,

Etymology and pronunciation

Metallurgy derives from the

In the late 19th century, metallurgy's definition was extended to the more general scientific study of metals, alloys, and related processes. In English, the /mɛˈtælərdʒi/ pronunciation is the more common one in the United Kingdom. The /ˈmɛtəlɜːrdʒi/ pronunciation is the more common one in the United States US and is the first-listed variant in various American dictionaries, including Merriam-Webster Collegiate and American Heritage.

History

The earliest recorded metal employed by humans appears to be gold, which can be found free or "native". Small amounts of natural gold have been found in Spanish caves dating to the late Paleolithic period, 40,000 BC.[7] Silver, copper, tin and meteoric iron can also be found in native form, allowing a limited amount of metalworking in early cultures.[8] Early metallurgy using native copper is documented at sites in Anatolia and at the site of Tell Maghzaliyah in Iraq, dating from the 7th/6th millennia BC.[9]

Certain metals, such as tin, lead, and copper can be recovered from their ores by simply heating the rocks in a fire or blast furnace in a process known as

The earliest documented use of lead (possibly native or smelted), dating from the 6th millennium BC, is from the late

Copper smelting is documented at sites in Anatolia and at the site of Tal-i Iblis in southeastern Iran from c. 5000 BC.[9]

Copper smelting is first documented in the

The Varna Necropolis, Bulgaria, is a burial site located in the western industrial zone of Varna, approximately 4 km from the city centre, internationally considered one of the key archaeological sites in world prehistory. The oldest gold treasure in the world, dating from 4,600 BC to 4,200 BC, was discovered at the site.[21] The gold piece dating from 4,500 BC, found in 2019 in Durankulak, near Varna is another important example.[22][23] Other signs of early metals are found from the third millennium BC in Palmela, Portugal, Los Millares, Spain, and Stonehenge, United Kingdom. The precise beginnings, however, have not be clearly ascertained and new discoveries are both continuous and ongoing.

In approximately 1900 BC, ancient iron smelting sites existed in Tamil Nadu. [24] [25]

In the Near East, about 3,500 BC, it was discovered that by combining copper and tin, a superior metal could be made, an alloy called bronze. This represented a major technological shift known as the Bronze Age.

The extraction of iron from its ore into a workable metal is much more difficult than for copper or tin. The process appears to have been invented by the Hittites in about 1200 BC, beginning the Iron Age. The secret of extracting and working iron was a key factor in the success of the Philistines.[26][27]

Historical developments in ferrous metallurgy can be found in a wide variety of past cultures and civilizations. This includes the ancient and medieval kingdoms and empires of the

A 16th century book by

Extraction

After mining, large pieces of the ore feed are broken through crushing or grinding in order to obtain particles small enough, where each particle is either mostly valuable or mostly waste. Concentrating the particles of value in a form supporting separation enables the desired metal to be removed from waste products.

Mining may not be necessary, if the ore body and physical environment are conducive to

Tailings of a previous process may be used as a feed in another process to extract a secondary product from the original ore. Additionally, a concentrate may contain more than one valuable metal. That concentrate would then be processed to separate the valuable metals into individual constituents.

Metal and its alloys

Much effort has been placed on understanding iron–carbon alloy system, which includes steels and cast irons. Plain carbon steels (those that contain essentially only carbon as an alloying element) are used in low-cost, high-strength applications, where neither weight nor corrosion are a major concern. Cast irons, including ductile iron, are also part of the iron-carbon system. Iron-Manganese-Chromium alloys (Hadfield-type steels) are also used in non-magnetic applications such as directional drilling.

Other engineering metals include aluminium, chromium, copper, magnesium, nickel, titanium, zinc, and silicon. These metals are most often used as alloys with the noted exception of silicon, which is not a metal. Other forms include:

- are used, where resistance to corrosion is important.

- Aluminium alloys and magnesium alloys are commonly used, when a lightweight strong part is required such as in automotive and aerospace applications.

- Copper-nickel alloys (such as Monel) are used in highly corrosive environments and for non-magnetic applications.

- Nickel-based superalloys like Inconel are used in high-temperature applications such as gas turbines, turbochargers, pressure vessels, and heat exchangers.

- For extremely high temperatures, single crystal alloys are used to minimize creep. In modern electronics, high purity single crystal silicon is essential for metal-oxide-silicon transistors (MOS) and integrated circuits.

Production

In

Determining the hardness of the metal using the Rockwell, Vickers, and Brinell hardness scales is a commonly used practice that helps better understand the metal's elasticity and plasticity for different applications and production processes.

Metalworking processes

- Casting – molten metal is poured into a shaped mold. Variants of casting include sand casting, investment casting, also called the lost wax process, die casting, and continuous castings. Each of these forms has advantages for certain metals and applications considering factors like magnetism and corrosion.[30]

- billetis hammered into shape.

- Rolling – a billet is passed through successively narrower rollers to create a sheet.

- Extrusion – a hot and malleable metal is forced under pressure through a die, which shapes it before it cools.

- milling machines and drillscut the cold metal to shape.

- Sintering – a powdered metal is heated in a non-oxidizing environment after being compressed into a die.

- gas cuttersand bent and welded into structural shape.

- Laser cladding – metallic powder is blown through a movable laser beam (e.g. mounted on a NC 5-axis machine). The resulting melted metal reaches a substrate to form a melt pool. By moving the laser head, it is possible to stack the tracks and build up a three-dimensional piece.

- 3D printing – Sintering or melting amorphous powder metal in a 3D space to make any object to shape.

Cold-working processes, in which the product's shape is altered by rolling, fabrication or other processes, while the product is cold, can increase the strength of the product by a process called work hardening. Work hardening creates microscopic defects in the metal, which resist further changes of shape.

Heat treatment

Metals can be

- Annealingprocess softens the metal by heating it and then allowing it to cool very slowly, which gets rid of stresses in the metal and makes the grain structure large and soft-edged so that, when the metal is hit or stressed it dents or perhaps bends, rather than breaking; it is also easier to sand, grind, or cut annealed metal.

- Quenching is the process of cooling metal very quickly after heating, thus "freezing" the metal's molecules in the very hard martensite form, which makes the metal harder.

- Tempering relieves stresses in the metal that were caused by the hardening process; tempering makes the metal less hard while making it better able to sustain impacts without breaking.

Often, mechanical and thermal treatments are combined in what are known as thermo-mechanical treatments for better properties and more efficient processing of materials. These processes are common to high-alloy special steels, superalloys and titanium alloys.

Plating

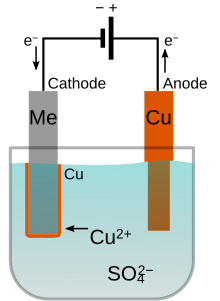

Electroplating is a chemical surface-treatment technique. It involves bonding a thin layer of another metal such as gold, silver, chromium or zinc to the surface of the product. This is done by selecting the coating material electrolyte solution, which is the material that is going to coat the workpiece (gold, silver, zinc). There needs to be two electrodes of different materials: one the same material as the coating material and one that is receiving the coating material. Two electrodes are electrically charged and the coating material is stuck to the work piece. It is used to reduce corrosion as well as to improve the product's aesthetic appearance. It is also used to make inexpensive metals look like the more expensive ones (gold, silver).[32]

Shot peening

Shot peening is a cold working process used to finish metal parts. In the process of shot peening, small round shot is blasted against the surface of the part to be finished. This process is used to prolong the product life of the part, prevent stress corrosion failures, and also prevent fatigue. The shot leaves small dimples on the surface like a peen hammer does, which cause compression stress under the dimple. As the shot media strikes the material over and over, it forms many overlapping dimples throughout the piece being treated. The compression stress in the surface of the material strengthens the part and makes it more resistant to fatigue failure, stress failures, corrosion failure, and cracking.[33]

Thermal spraying

Thermal spraying techniques are another popular finishing option, and often have better high temperature properties than electroplated coatings. Thermal spraying, also known as a spray welding process,[34] is an industrial coating process that consists of a heat source (flame or other) and a coating material that can be in a powder or wire form, which is melted then sprayed on the surface of the material being treated at a high velocity. The spray treating process is known by many different names such as HVOF (High Velocity Oxygen Fuel), plasma spray, flame spray, arc spray and metalizing.

Electroless deposition

Electroless deposition (ED) or electroless plating is defined as the

Characterization

In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or electron microscope, and the image contrast provides details on the composition, mechanical properties, and processing history.

Crystallography, often using diffraction of x-rays or electrons, is another valuable tool available to the modern metallurgist. Crystallography allows identification of unknown materials and reveals the crystal structure of the sample. Quantitative crystallography can be used to calculate the amount of phases present as well as the degree of strain to which a sample has been subjected.

See also

- Adrien Chenot

- Archaeometallurgy

- Blacksmith

- CALPHAD

- Carbonyl metallurgy

- Cupellation

- Experimental archaeometallurgy

- Forging

- Goldbeating

- Gold phosphine complex

- Metallurgical failure analysis

- Metalworking

- Mineral industry

- Pyrometallurgy

- Welding

References

- ISBN 978-0408053693.

- ISBN 978-8120351707. Archivedfrom the original on 24 June 2021. Retrieved 20 September 2020.

- ^ "Металлургия" Archived 18 January 2015 at the Wayback Machine. in The Great Soviet Encyclopedia. 1979.

- ^ ISBN 0901462888

- ^ ISBN 978-0233002026.

- Oxford Learner's Dictionary. Oxford University Press. Archivedfrom the original on 1 August 2014. Retrieved 29 January 2011.

- ^ "History of Gold". Gold Digest. Archived from the original on 29 April 2007. Retrieved 4 February 2007.

- (PDF) from the original on 22 December 2015. Retrieved 1 January 2015.

- ^ ISBN 978-1-4443-6077-6.

- ^ H.I. Haiko, V.S. Biletskyi. First metals discovery and development the sacral component phenomenon. // Theoretical and Practical Solutions of Mineral Resources Mining // A Balkema Book, London, 2015, р. 227-233. Archived 8 December 2015 at the Wayback Machine.

- S2CID 237005605.

- .

- ^ Neolithic Vinca was a metallurgical culture Archived 19 September 2017 at the Wayback Machine Stonepages from news sources November 2007

- ISBN 9780691143880.

- .

- ISBN 9780199689170.

The scale and technical quality of the Carpathian-Balkan copper industry totally overshadows that of any other contemporary production centre. This, together with the late sixth-millennium date for its beginning, gives strong support to the suggestion that the art of copper smelting was first perfected in the Balkans. The region can also claim to be the first to produce gold, beginning in the mid-fifth millennium, five hundred years or more before the earliest gold objects appear in the Near East.

- .

The general area of the Carpatho-Balkan Metallurgical Province (CBMP) equaled approximately 1.5 million sq. km spread from the Danubian basin in the Western flank to the Mid and Lower Volga basin in the Eastern flank of this province. The most characteristic features of the CBMP are 1) casting and hammering of various heavy tools and weapons made from chemically pure copper; 2) a big number of gold decorations and ornaments. Metallurgical revolution and CBMP formation emerged independently from centers of the Proto-Metal area [in the Middle East] where in the 5th millennium BCE there continued a limited production of primitive handmade copper goods.

- ISBN 978-3-86757-010-7.

- ISBN 978-1444360776. Archivedfrom the original on 21 September 2020. Retrieved 19 March 2022.

- ISBN 978-3-319-11640-2.

Egypt and adjacent regions closely mimic the metallurgical trajectories of the nearby Middle East. Egyptian metallurgy started with the working of copper around 4000 BC. (p.17) The earliest evidence for metallurgy in Africa comes from the Nile Delta in Egypt and is associated with the Maadi culture dating between 4000 and 3200 BC. (p.19)

- ^ [1] Archived 12 February 2020 at the Wayback Machine Gems and Gemstones: Timeless Natural Beauty of the Mineral World, By Lance Grande

- ^ "World's oldest gold". Archived from the original on 28 September 2019. Retrieved 28 September 2019.

- ^ Magazine, Smithsonian; Daley, Jason. "World's Oldest Gold Object May Have Just Been Unearthed in Bulgaria". Smithsonian Magazine. Archived from the original on 28 September 2019. Retrieved 28 September 2019.

- ^ "Ancient Smelting in Tamil Nadu India". www.indianexpress.com. 14 May 2022. Archived from the original on 4 October 2022. Retrieved 27 October 2023.

- ^ "Ancient high-carbon steel from southern Tamil Nadu India microstructural and elemental analysis" (PDF). www.currentscience.ac.in. Archived (PDF) from the original on 20 June 2023. Retrieved 27 October 2023.

- ISBN 034000312X

- ISBN 0582485983

- doi:10.5962/bhl.title.33301. Archived from the originalon 4 March 2016. Retrieved 1 January 2015.

- ^ "Metal Hardness Tests: Difference Between Rockwell, Brinell, and Vickers". ESI Engineering Specialties Inc. 14 June 2017. Archived from the original on 14 December 2017. Retrieved 13 December 2017.

- ^ "Casting Process, Types of Casting Process, Casting Process Tips, Selecting Casting Process, Casting Process Helps". www.themetalcasting.com. Archived from the original on 18 December 2017. Retrieved 13 December 2017.

- ISBN 978-1615038213

- ^ Woodford, Chris (2017). "How electroplating works". Explain that Stuff. Archived from the original on 15 June 2019. Retrieved 20 May 2019.

- ^ "What is Shot Peening – How Does Shot Peening Work". www.engineeredabrasives.com. Archived from the original on 12 June 2018. Retrieved 4 January 2019.

- ^ "Thermal Spray, Plasma Spray, HVOF, Flame Spray, Metalizing & Thermal Spray Coating". www.precisioncoatings.com. Saint Paul, MN. Archived from the original on 14 August 2022. Retrieved 13 December 2017.