User:R8R/sandbox

User:R8R/Rethinking rules on spellings of elements

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Lead | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pronunciation | /ˈlɛd/ | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Appearance | metallic gray | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard atomic weight Ar°(Pb) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Lead in the periodic table | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7000 BCE) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Symbol | "Pb": from Latin plumbum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Isotopes of lead | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Isotopic abundances vary greatly by sample[5] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lead is a

Lead is a relatively unreactive

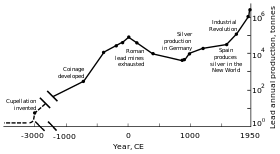

Lead is easily extracted from its ores and was known to prehistoric people in Western Asia. A principal ore of lead, galena, often bears silver, and interest in silver helped initiate widespread lead extraction and use in ancient Rome. Lead production declined after the fall of Rome and did not reach comparable levels again until the Industrial Revolution. Nowadays, global production of lead is about ten million tonnes annually; secondary production from recycling accounts for more than half of that figure.

Lead has several properties that make it useful: high density, low melting point, ductility, and relative inertness to

Physical properties

Atomic

A lead atom has 82 electrons, arranged in an

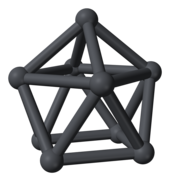

The lighter group 14 elements form stable or metastable

Bulk

Freshly prepared lead has a bright silvery appearance with a hint of blue

Lead's close packed face-centered cubic structure and high atomic weight result in a density[15] of 11.34 g/cm3, which is greater than that of common metals such as iron (7.87 g/cm3), copper (8.93 g/cm3), and zinc (7.14 g/cm3).[16] It is the origin of the idiom to go over like a lead balloon.[17] Some rarer metals are denser: tungsten and gold are both 19.3 g/cm3, and osmium— the densest metal known—has a density of 22.59 g/cm3, almost twice that of lead.[18]

Lead is a very soft metal with a

The melting point of lead—at 327.5 °C (621.5 °F)

Isotopes

Isotopic abundances vary greatly by sample talk | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Natural lead consists of four stable isotopes with mass numbers of 204, 206, 207, and 208,[30] and traces of five short-lived radioisotopes.[31] The high number of isotopes is due to lead's atomic number of 82 being even,[e] as well as a magic number (meaning lead's protons form complete shells within its atomic nucleus).[f] With its high atomic number, lead is the heaviest element whose natural isotopes are regarded as stable. This title was formerly held by bismuth, with an atomic number of 83, but its only primordial isotope was found in 2003 to decay at an extremely gradual rate.[g] The four stable isotopes of lead could theoretically undergo alpha decay to isotopes of mercury with a release of energy, but this has not been observed for any of them;[32] their predicted half-lives range from 1035 to 10189 years.[35]

Three of the stable isotopes are found in three of the four major

Apart from the stable isotopes, which make up almost all lead that exists naturally, there are

In total, forty-three lead isotopes have been synthesized, with mass numbers 178–220.[32] Lead-205 is the most stable, with a half-life of around 1.5×107 years.[h] The second-most stable is the synthetic lead-202, which has a half-life of about 53,000 years, longer than any of the natural trace radioisotopes.[32]

Chemistry

Bulk lead exposed to moist air forms a protective layer of varying composition.

The action of water on lead has the potential to make lead plumbing dangerous.[48] An excess of dissolved carbon dioxide in the carried water may result in the formation of soluble lead bicarbonate; oxygenated water may similarly dissolve lead as lead(II) hydroxide.[49] Drinking such water, over time, has the potential to cause health problems due to the toxicity of the dissolved lead.[i]

Fluorine reacts with lead at room temperature, forming lead(II) fluoride. The reaction with chlorine is similar but requires heating as the resulting chloride layer diminishes the reactivity of the elements.[45][51] Molten lead reacts with the chalcogens to give lead(II) chalcogenides.[52]

Lead metal is not attacked by dilute

Inorganic compounds

Lead shows two main oxidation states: +4 and +2. The

There is a relatively large difference in the electronegativity of lead(II) at 1.87 and lead(IV) at 2.33. This difference marks the reversal in the trend of increasing stability of the +4 oxidation state going down group 14; tin, by comparison, has values of 1.80 in the +2 oxidation state and 1.96 in the +4 state.[54]

Lead(II)

Lead(II) compounds are characteristic of the inorganic chemistry of lead. Even strong

Lead monoxide exists in two

Lead dihalides are well-characterized; this includes the diastatide,

4]2−

, [PbCl

6]4−

, and the [Pb

2Cl

9]5n−

n chain anion.[62]

Lead(IV)

Few inorganic lead(IV) compounds are known, and these are typically strong oxidants or exist only in highly acidic solutions.

Other oxidation states

Some lead compounds exist in formal oxidation states other than +4 or +2. Lead(III) may be obtained, as an intermediate between lead(II) and lead(IV), in larger organolead complexes.[69][70] This oxidation state is not stable as the both the lead(III) ion and the larger complexes containing it are radicals; the same applies for lead(I), which can be found in such species.[71]

Numerous mixed lead(II,IV) oxides are known. When PbO2 is heated in air, it becomes Pb12O19 at 293 °C, Pb12O17 at 351 °C, Pb3O4 at 374 °C, and finally PbO at 605 °C. A further sesquioxide Pb2O3 can be obtained at high pressure, along with several non-stoichiometric phrases. Many of them show defect fluorite structures in which some oxygen atoms are replaced by vacancies: for instance, PbO can be considered as having such a structure, with every alternate layer of oxygen atoms absent.[72]

Negative oxidation states can occur as

Organolead

Carbon

Hydrogen

Lead

Lead can form multiply bonded chains, a property it shares with its lighter homolog, carbon. Its capacity to do so is much less because the Pb–Pb bond energy (98 kJ/mol) is far lower than that of the C–C bond (356 kJ/mol).[52] With itself lead can build metal–metal bonds of an order up to three.[76] With carbon, lead forms organolead compounds similar to, but generally less stable than, typical organic compounds[77] (due to the Pb–C bond being rather weak).[57] This makes the organometallic chemistry of lead far less wide-ranging than that of tin.[78] It predominantly forms organolead(IV) compounds. Very few organolead(II) compounds are known: even starting with inorganic lead(II) reactants results in organolead(IV) products. The most well-characterized exceptions are the purple bis(disyl)plumbylene, Pb[CH(SiMe)3)2]2 and lead cyclopentadienide, Pb(η5-C5H5)2.[78]

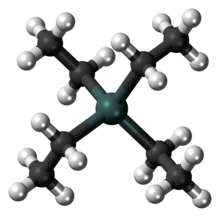

The simplest

Origin and occurrence

In space

| Atomic number |

Element | Relative amount |

|---|---|---|

| 42 | Molybdenum | 0.798 |

| 46 | Palladium | 0.440 |

| 50 | Tin | 1.146 |

| 78 | Platinum | 0.417 |

| 80 | Mercury | 0.127 |

| 82 | Lead | 1 |

| 90 | Thorium | 0.011 |

| 92 | Uranium | 0.003 |

Lead 's per-particle abundance in the

Primordial lead—which comprises the isotopes lead-204, lead-206, lead-207, and lead-208—was mostly created as a result of repetitive neutron capture processes occurring in stars. The two main modes of capture are the s- and r-processes.[86]

In the s-process (s is for "slow"), captures are separated by years or decades, allowing less stable nuclei to beta decay. For example, a stable thallium-203 nucleus captures a neutron and becomes thallium-204; this undergoes beta decay to give stable lead-204; on capturing another neutron, it becomes lead-205, which is stable enough to generally last longer than a capture takes (its half-life is around 15 million years). Further captures result in lead-206, lead-207, and lead-208. On capturing another neutron, lead-208 becomes lead-209, which quickly decays into bismuth-209. On capturing another neutron, bismuth-209 becomes bismuth-210, and this undergoes alpha decay to thallium-206 (which beta decays to lead-206), or beta decays to polonium-210 (which alpha decays to lead-206). The cycle ends at lead-206, lead-207, lead-208, and bismuth-209.[86]

In the r-process (r is for "rapid"), captures happen faster than nuclei can decay. This occurs in environments with a high neutron density, such as a supernova or the merger of two neutron stars. The neutron flux involved may be on the order of 1022 neutrons/(cm2·second).[87] The r-process does not form as much lead as the s-process. It tends to stop once neutron-rich nuclei reach 126 neutrons. At this point, the neutrons are arranged in complete shells within the atomic nucleus, and it becomes harder to energetically accommodate more of them. When the neutron flux subsides, these nuclei beta decay into stable isotopes of osmium, iridium, and platinum.[86]

On Earth

Lead is classified as a

The main lead-bearing mineral is galena (PbS), which is mostly found with zinc ores.[88] Most other lead minerals are related to galena in some way; for example, boulangerite, Pb

5Sb

4S

11, is a mixed sulfide derived from galena; anglesite, PbSO

4, is a product of galena oxidation; and cerussite or white lead ore, PbCO

3, is a decomposition product of galena. Arsenic, tin, antimony, silver, gold, and bismuth are common impurities in lead minerals.[88]

World lead resources exceed 2 billion tons.[91] Significant deposits are located in Australia, China, Ireland, Mexico, Peru, Portugal, Russia, and the United States. Global reserves—resources that are economically feasible to extract—totaled 89 million tons in 2015, of which Australia had 35 million, China 15.8 million, and Russia 9.2 million.[91]

Typical background concentrations of lead do not exceed 0.1 μg/m3 in the atmosphere; 100 mg/kg in soil; and 5 μg/L in freshwater and seawater.[92]

Etymology

The modern English word "lead" is of Germanic origin; it comes from the Middle English leed and Old English lēad (with the macron above the "e" signifying that the vowel sound of that letter is long).[93] The Old English word is derived from the hypothetical reconstructed Proto-Germanic *lauda- ("lead").[94] According to accepted linguistic theory, this word bore descendants in most Germanic languages of exactly the same meaning.

The origin of the Proto-Germanic *lauda- is not agreed within the linguistic community. One hypothesis suggests it is derived from

The name of the chemical element is not related to the verb of the same spelling, which is instead derived from (eventually) Proto-Germanic *laidijan- ("to lead").[97]

History

(Years B.P. = years before 1950)[98]

Prehistory and early history

Metallic lead beads

Classical era

Because silver was extensively used as a decorative material and an exchange medium, lead deposits came to be worked in Asia Minor from 3000 BC,

This metal was by far the most used material in classical antiquity, and it is appropriate to refer to the (Roman) Lead Age. Lead was to the Romans what plastic is to us.

Heinz Eschnauer and Markus Stoeppler

"Wine—An enological specimen bank", 1992[106]

Rome's territorial expansion in Europe and across the Mediterranean, and its development of mining, led to it becoming the greatest producer of lead during the classical era, with an estimated annual output peaking at 80,000 tonnes. Like their predecessors, the Romans obtained lead mostly as a by-product of silver smelting.[98][107][108] Lead mining occurred in Central Europe, Britain, the Balkans, Greece, Anatolia, and Hispania, with the latter accounting for 40% of world production.[98]

Lead was used for making

The Roman author Vitruvius reported the health dangers of lead[114] and modern writers have suggested that lead poisoning played a major role in the decline of the Roman Empire.[115][116][m] Other researchers have criticized such claims, citing errors in linking the fall of Rome to lead poisoning, and even "false evidence".[118][119] According to archaeological research, Roman lead pipes increased lead levels in tap water but such an effect was "unlikely to have been truly harmful".[120][121] When lead poisoning did occur, victims were called "saturnine" after the ghoulish father of the gods, Saturn, since they became dark and cynical. By association, lead was considered the father of all metals.[122] Its social status was low as it was readily available in Roman society[123] and cheap.[124]

Confusion with tin and antimony

During the classical era (and even up to the 17th century), tin was often not distinguished from lead: Romans called lead plumbum nigrum ("black lead"), and tin plumbum candidum ("bright lead"). The association of lead and tin can be seen in other languages: the word olovo in Czech translates to "lead", but in Russian the cognate олово (olovo) means "tin".[125] To add to the confusion, lead bore a close relation to antimony: both elements commonly occur as sulfides (galena and stibnite), often together. Pliny wrote that stibnite would give lead on heating, whereas the mineral produced on heating was antimony.[126] In countries such as Turkey and India, the originally Persian name surma came to refer to either antimony sulfide or lead sulfide,[127] and in some languages, such as Russian, gave its name to antimony (сурьма).[128]

Middle Ages and the Renaissance

Lead mining in Western Europe declined after the fall of the Western Roman Empire, with Arabian Iberia being the only region having a significant output.[130][131] The largest production of lead occurred in South and East Asia, especially China and India, where lead mining grew strongly.[131]

In Europe, lead production only began to revive in the 11th and 12th centuries, where it was again used for roofing and piping; from the 13th century, lead was used to create

Outside Europe and Asia

In the

Industrial Revolution

In the second half of the 18th century Britain, and later continental Europe and the United States, experienced the Industrial Revolution. During the period, lead mining proved important; the Industrial Revolution was the first time during which production rates exceeded those of Rome.[98] Britain was the leading producer, losing this status by the mid-19th century with the depletion of its mines and the development of lead mining in Germany, Spain, and the United States.[144] By 1900, the United States dominated global lead production,[145] and other non-European nations—Canada, Mexico, and Australia—had begun significant production.[146] A great share of the demand for lead came from plumbing and painting—lead paints were in regular use.[147] At this time, more (working class) people contacted the metal and lead poisoning cases escalated. This led to research into the effects of lead intake. Lead was proven to be more dangerous in its fume form than as a solid metal. Lead poisoning and gout were linked; British physician Alfred Baring Garrod noted a third of his gout patients were plumbers and painters. The effects of chronic ingestion of lead, including mental disorders, were also studied in the 19th century. The first laws aimed at decreasing lead poisoning in factories were enacted during the 1870s and 1880s in the United Kingdom.[147]

Modern era

Further evidence of the threat that lead posed to humans was discovered in the late 19th and early 20th centuries. Mechanisms of harm were better understood, and lead blindness was documented. Countries in Europe and the United States started efforts to reduce the amount of lead that people came into contact with. The United Kingdom first introduced mandatory factory inspections in 1878 and appointed the first Medical Inspector of Factories in 1898; as a result, a 25-fold decrease in lead poisoning incidents from 1900 to 1944 was reported.

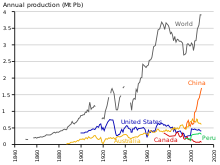

Production

Production and consumption of lead is increasing worldwide due to its use in lead–acid batteries.[156] There are two major categories of production: primary, from mined ores; and secondary from scrap. In 2013, 4.74 million metric tons came from primary production and 5.74 million from secondary production. The top three producers of mined lead concentrate in that year were China, Australia, and the United States. The top three producers of refined lead were China, the United States, and Germany.[157] According to the International Resource Panel's Metal Stocks in Society report of 2010, the total amount of lead in use, stockpiled, discarded or dissipated into the environment, on a global per capita basis, is 8 kg. Much of this is in more developed countries (20–150 kg per capita) rather than less developed ones (1–4 kg per capita).[158]

Production processes for primary and secondary lead are similar. Some primary production plants now supplement their operations with scrap lead, and this trend is likely to increase in the future. Given adequate techniques, secondary lead is indistinguishable from primary lead. Scrap lead from the building trade is usually fairly clean and is re-melted without the need for smelting, though refining is sometimes needed. Secondary lead production is therefore cheaper, in terms of energy requirements, than is primary production, often by 50% or more.[159]

Primary

Most lead ores contain a low percentage of lead—lead-rich ores have a typical content of 3–8%—which must be concentrated for extraction.[160] During initial processing, ores typically undergo crushing, dense-medium separation, grinding, froth flotation, and drying. The resulting concentrate, which has a lead content of 30–80% by mass (regularly 50–60%),[160] is then turned into (impure) lead metal.

There are two main ways of doing this: a two-stage process involving roasting followed by blast furnace extraction, carried out in separate vessels; or a direct process in which the extraction of the concentrate occurs in a single vessel. The latter has become the most common route, though the former is still significant.[161]

Two-stage process

First, the sulfide concentrate is roasted in air to oxidize the lead sulfide:[162]

- 2 PbS + 3 O2 → 2 PbO + 2 SO2↑

| Country | Output (thousand tons) |

|---|---|

| 2,300 | |

| 633 | |

| 385 | |

| 300 | |

| 240 | |

| 130 | |

| 90 | |

| 82 | |

| 76 | |

| 54 | |

| 45 | |

| 40 | |

| 40 | |

| 38 | |

| 33 | |

| Other countries | 226 |

As the original concentrate was not pure lead sulfide, roasting yields lead oxide and a mixture of

- 2 PbO + C → Pb + CO2↑

Impurities are mostly arsenic, antimony, bismuth, zinc, copper, silver, and gold. The melt is treated in a reverberatory furnace with air, steam, and sulfur, which oxidizes the impurities except for silver, gold, and bismuth. Oxidized contaminants float to the top of the melt and are skimmed off.[166][167] Metallic silver and gold are removed and recovered economically by means of the Parkes process, in which zinc is added to lead. The zinc adsorbs silver and gold, both of which, being immiscible in lead, can be separated and retrieved.[168][167] De-silvered lead is freed of bismuth by the Betterton–Kroll process, treating it with metallic calcium and magnesium. The resulting bismuth dross can be skimmed off.[167]

Very pure lead can be obtained by processing smelted lead electrolytically using the

Direct process

In this process lead bullion and slag is obtained directly from lead concentrates. The lead sulfide concentrate is charged directly to a furnace, melted, and oxidized, forming lead monoxide. Carbon (coke or gas) is added to the molten charge along with fluxing agents. The lead monoxide is thereby reduced to metallic lead, in the midst of a slag rich in lead monoxide.

As much as 80% of the lead in very high-content initial concentrates can be obtained as bullion; the remaining 20% resides in a slag rich in lead monoxide. For a low-grade feed, all of the lead can be oxidized to a high-lead slag.[161] Metallic lead is further obtained from the high-lead (25–40%) slags via submerged fuel combustion or injection, reduction assisted by an electric furnace, or a combination of both.[161]

Alternatives

Research on a cleaner, less energy-intensive, lead extraction process continues; a major drawback is that the alternatives result in either a high sulfur content in the resulting lead metal, or too much lead is lost as waste. Hydrometallurgical extraction, in which anodes of impure lead are immersed into an electrolyte and pure lead is deposited onto a cathode, is technique that may have potential.[170]

Secondary

Smelting, which is an essential part of the primary production, is often skipped during secondary production. It is only performed when metallic lead had undergone significant oxidation.

Of the sources of lead for recycling, lead–acid batteries are the most important; lead pipe, sheet, and cable sheathing are also significant.[159]

Applications

Contrary to popular belief, pencil leads in wooden pencils have never been made from lead. When the pencil originated as a wrapped graphite writing tool, the particular type of

Elemental form

Lead metal has several useful mechanical properties, including high density, low melting point, ductility, and relative inertness. Many metals are superior to lead in some of these aspects but lead is more common than most of these metals, and lead-bearing minerals are easier to mine and process than those of many other metals. One disadvantage of using lead is its toxicity, which explains why it has been phased out for some uses.[174]

Lead has been used for bullets since their invention in the Middle Ages. It is inexpensive; its low melting point means small arms ammunition and shotgun pellets can be cast with minimal technical equipment; and it is denser than other common metals (which allows for better retention of velocity). In cast bullets, lead is sometimes alloyed with tin or antimony: this increases the cost and time of making the bullet, but increases its hardness (thereby making the bullet more effective against hard targets), reduces tension on the gun barrel and does not contaminate it with lead, as simple lead bullets do.[175]. Concerns have been raised that lead bullets used for hunting can damage the environment.[o]

Its high density and resistance to corrosion have been exploited in a number of related applications. It used as

The high density and atomic number of lead, combined with its relatively low cost, malleability and low melting point, helped establish lead as a radiation shielding material. A gamma ray, for example, can be absorbed by an electron, potentially knocking it out from its atom. The high density of lead means that lead atoms are densely packed and the electron density is high; the high atomic number means there are many electrons per atom.[181] In its molten form, it has been used as a coolant for lead-cooled fast reactors.[182]

Lead is added to copper alloys such as

Sheet-lead is used as a sound deadening layer in the walls, floors and ceilings of sound studios.[184][185] It is the traditional base metal of organ pipes, mixed with various amounts of tin to control the tone of each pipe.[186][187]

Lead has many uses in the construction industry; for example, lead sheets are used as architectural metals in roofing material, cladding, flashing, gutters and gutter joints, and on roof parapets.[188][189] Detailed lead moldings are used as decorative motifs to fix lead sheet. Lead is still used in statues and sculptures,[p] including for armatures.[191] In the past it was often used to balance the wheels of a car; for environmental reasons this use is being phased out in favor of other materials.[192]

The largest use of lead in the early 21st century is in

Lead is used in

Compounds

Lead compounds are used as, or in, coloring agents, oxidants, plastic, candles, glass, and semiconductors. Lead-based coloring agents are used in

Biological and environmental effects

Biological

Lead has no confirmed biological role.[204] Its prevalence in the human body—at an adult average of 120 mg[r]—is nevertheless exceeded only by zinc (2500 mg) and iron (4000 mg) of all metals.[206] Lead salts are very quickly and efficiently absorbed by the body.[207] A small amount of lead (1%) will be stored in bones; the rest will be excreted in urine and feces within a few weeks of exposure. Only about a third of lead will be excreted by a child. Continuous exposure may result in the bioaccumulation of lead.[208]

Toxicity

Lead is a highly poisonous metal (whether inhaled or swallowed), affecting almost every organ and system in the human body.

Effects

Lead can cause severe damage to the brain and kidneys in adults or children and, ultimately, death. By mimicking calcium, lead can cross the

Symptoms of lead poisoning include

Despite the toxicity of lead in significant amounts, there is some evidence that trace amounts are beneficial in pigs and rats, and that its absence causes deficiencies such as depressed growth, anemia, and disturbed iron metabolism. If this finding holds for humans it would make lead an essential element, one with a threshold of toxicity so low that lead toxicity would remain a much higher priority than lead deficiency.[220][221][222][223]

Treatment

Treatment for lead poisoning normally involves the administration of

Exposure sources

Lead exposure is a global issue as lead mining and lead smelting are common in many countries. Poisoning typically results from ingestion of food or water contaminated with lead, and less commonly after accidental ingestion of contaminated soil, dust, or lead-based paint.[226] Fruit and vegetables can be contaminated by high levels of lead in the soils they were grown in. Soil can be contaminated through particulate accumulation from lead in pipes, lead paint, and residual emissions from leaded gasoline.[227] The use of lead for water pipes is problematic in areas with soft or acidic water. Hard water forms insoluble layers in the pipes whereas soft and acidic water dissolves the lead pipes.[228]

Ingestion of lead-based paint is the major source of exposure for children. As the paint deteriorates, it peels, is pulverized into dust and then enters the body through hand-to-mouth contact or contaminated food, water, or alcohol. Ingesting certain

Dermal exposure may be significant for a narrow category of people working with organic lead compounds. The rate of skin absorption is lower for inorganic lead.[233]

Environmental

The extraction, production, use, and disposal of lead and its products have caused significant contamination of the Earth's soils and waters. Atmospheric emissions of lead were at their peak during the Industrial Revolution and the leaded gas period in the second half of the twentieth century. Elevated concentrations of lead persist in soils and sediments in post-industrial and urban areas, and industrial emissions, including those arising from coal burning,[234] continue in many parts of the world.[235]

Lead can accumulate in soils, especially those with a high organic content, where it remains for hundreds to thousands of years. It can take the place of other metals within plants and can accumulate on their surfaces, thereby retarding photosynthesis, and preventing their growth or killing them. Contamination of soils and plants then affects microorganisms and animals. Affected animals have a reduced ability to synthesize red blood cells.

Restriction and remediation

By the mid-1980s, a significant shift in lead use had taken place. In the United States, environmental regulations reduced or eliminated the use of lead in non-battery products, including gasoline, paints, solders, and water systems. Particulate control devices can be used in

In the United States, the Occupational Safety and Health Administration has set the permissible exposure limit for lead exposure in the workplace as 0.05 mg/m3 over an 8-hour workday; this applies to metallic lead, inorganic lead compounds, and lead soaps. The US National Institute for Occupational Safety and Health has set a recommended exposure limit of 0.05 mg/m3 over an 8-hour workday and recommends that workers' blood concentrations of lead stay below 0.06 mg per 100 g of blood.

Lead may still be found in harmful quantities in stoneware,

Lead waste, depending of the jurisdiction and the nature of the waste, may be treated as household waste (in order to facilitate lead abatement activities),[243] or potentially hazardous waste requiring specialized treatment or storage.[244] Research has been conducted on how to remove lead from biosystems by biological means. Fish bones are being researched for their ability to bioremediate lead in contaminated soil.[245][246] The fungus Aspergillus versicolor is effective at removing lead ions.[247] Several bacteria have been researched for their ability to reduce lead, including the sulfate-reducing bacteria Desulfovibrio and Desulfotomaculum, both of which are highly effective in aqueous solutions.[248]

See also

Notes

- relativistic effects.[8]

- ^ The allotrope was obtained by depositing lead atoms on the surface of an icosahedral silver-indium-ytterbium quasicrystal. Its electronic nature—whether it was metallic or an insulator (or something in between)—was not recorded.[12][13]

- ^ Malleability describes how easily it deforms under compression, whereas ductility means its ability to stretch.

- ^ A (wet) finger can be dipped into molten lead without risk of a burning injury.[25]

- ^ An even number of either protons or neutrons generally increases the nuclear stability of isotopes, compared to isotopes with odd numbers. No elements with odd atomic number has more than two stable isotopes; even-numbered elements have multiple stable isotopes, with tin (element 50) having the highest number of isotopes of all elements, ten.[32] See Even and odd atomic nuclei for more details.

- ^ Lead 208 is doubly magic, and especially stable against decay, as its 126 neutrons also form a complete shell.

- ^ The half-life found in the experiment was 1.9×1019 years.[33] A kilogram of natural bismuth would have an activity value of approximately 0.003 becquerels (decays per second). For comparison, the activity value of natural radiation within the human body is around 65 becquerels per kilogram of body weight (4500 becquerels on average).[34]

- ^ It decays solely via electron capture, which means when there are no electrons available and lead is fully ionized with all 82 electrons removed it cannot decay. Fully ionized thallium-205, the isotope lead-205 would decay to, becomes unstable and can decay into a bound state of lead-205.[41]

- ^ The harder the water the more calcium bicarbonate and sulfate it will contain, and the more the inside of the pipes will be coated with a protective layer of lead carbonate or lead sulfate.[50]

- ^ Abundances in the source are listed relative to silicon rather than in per-particle notation. The sum of all elements per 106 parts of silicon is 2.6682×1010 parts; lead comprises 3.258 parts.

- ^ Elemental abundance figures are estimates and their details may vary from source to source.[90]

- Gnaeus Iulius Agricolawas imperial governor (of Britain)."

- Caesar Augustus, have been attributed to lead poisoning.[117]

- ^ It is not known when mining was first performed in the region because no written records were kept, but there are 17th-century European records of trade with the Congolese, which indicate lead was being smelted by then.[143]

- ^ For instance, California banned lead bullets for hunting on that basis in April 2015.[176]

- ^ For example, a firm "...producing quality [lead] garden ornament from our studio in West London for over a century".[190]

- ^ See[193] for details on how a lead–acid battery works.

- ^ Rates vary greatly by country.[205]

- ^ An alloy of brass (copper and zinc) with lead, iron, tin, and sometimes antimony.[240]

References

- ^ "Standard Atomic Weights: Lead". CIAAW. 2020.

- ^ ISSN 1365-3075.

- PMID 15740207.

- ^ .

- ^ a b c Meija et al. 2016.

- ^ Lide 2004, p. 10-179.

- ^ a b c Polyanskiy 1986, pp. 14–15.

- ^ Pyykko 1988, pp. 563–94.

- ^ Norman 1996, p. 36.

- ^ Greenwood & Earnshaw 1998, pp. 374, 226–27.

- ^ Christensen 2002, pp. 867–68.

- ^ Sharma et al. 2013.

- ^ Sharma et al. 2014, p. 174710.

- ^ a b Polyanskiy 1986, p. 18.

- ^ Thornton, Rautiu & Brush 2001, p. 6.

- ^ Lide 2004, pp. 12-35–12-37.

- ^ Jones 2014, p. 42.

- ^ Lide 2004, pp. 4-39–4-96.

- ^ Vogel & Achilles 2013, p. 8.

- ^ Anderson 1869, pp. 341–43.

- ^ Gale & Totemeier 2003, pp. 15–2–15–3.

- ^ Thornton, Rautiu & Brush 2001, p. 8.

- ^ Lide 2004, p. 12-220.

- ^ Koshal 2014, p. 1/92.

- ^ Willey 1999.

- ^ Lide 2004, p. 12-219.

- ^ Blakemore 1985, p. 272.

- ^ Webb, Marsiglio & Hirsch 2015.

- ^ "Standard Atomic Weights: Lead". CIAAW. 2020.

- ^ Polyanskiy 1986, p. 16.

- ^ University of California Berkeley Nuclear Forensic Search Project.

- ^ a b c d e Livechart.

- ^ Marcillac et al. 2003, pp. 876–78.

- ^ Nuclear Radiation and Health Effects 2015.

- ^ Beeman, Bellini & Cardani 2013.

- ^ Smirnov, Borisevich & Sulaberidze 2012, pp. 373–78.

- ^ Greenwood & Earnshaw 1998, p. 368.

- ^ Boltwood 1907, pp. 77–88.

- ^ Fiorini 2010, pp. 7–8.

- ^ Nosengo 2010.

- ^ Takahashi et al. 1987.

- ^ Thurmer, Williams & Reutt-Robey 2002, pp. 2033–35.

- ^ Tétreault, Sirois & Stamatopoulou 1998, pp. 17–32.

- ^ Thornton, Rautiu & Brush 2001, pp. 10–11.

- ^ a b c d Greenwood & Earnshaw 1998, p. 373.

- ^ Charles, Kopf & Toby 1966, pp. 1478–82.

- ^ Harbison, Bourgeois & Johnson 2015, p. 132.

- ^ a b Polyanskiy 1986, p. 20.

- ^ a b c Polyanskiy 1986, p. 32.

- ^ Wiberg, Wiberg & Holleman 2001, p. 914.

- ^ Polyanskiy 1986, p. 19.

- ^ a b Greenwood & Earnshaw 1998, p. 374.

- ^ Kaupp 2014, pp. 9–10.

- ^ Rappoport & Marek 2010, p. 509.

- ^ a b c Greenwood & Earnshaw 1998, p. 389.

- ^ Ensafi, Far & Meghdadi 2009, pp. 1069–75.

- ^ a b c King 1995, pp. 43–63.

- ^ Whitten, Gailey & David 1996, pp. 904–5.

- ^ Greenwood & Earnshaw 1998, p. 384.

- ^ Wiberg, Wiberg & Holleman 2001, p. 916.

- ^ Zuckerman & Hagen 1989, p. 426.

- ^ a b Greenwood & Earnshaw 1998, p. 382.

- ^ Greenwood & Earnshaw 1998, p. 388.

- ^ Bremholm, Hor & Cava 2011, pp. 38–41.

- ^ Silverman 1966, pp. 2067–69.

- ^ Greenwood & Earnshaw 1998, p. 398.

- ^ Macomber 1996, p. 230.

- ^ Yong, Hoffmann & Fässler 2006, pp. 4774–78.

- ^ Becker et al. 2008, pp. 9965–78.

- ^ Mosseri, Henglein & Janata 1990, pp. 2722–26.

- ^ Chia et al. 2013, pp. 6298–301.

- ^ Greenwood & Earnshaw 1998, p. 386.

- ^ Röhr.

- ^ Alsfasser 2007, pp. 261–63.

- ^ Greenwood & Earnshaw 1998, p. 393.

- ^ Stabenow, Saak & Weidenbruch 2003, pp. 2342.

- ^ a b c Polyanskiy 1986, p. 43.

- ^ a b c Greenwood & Earnshaw 1998, p. 404.

- ^ a b Wiberg, Wiberg & Holleman 2001, p. 918.

- ^ Polyanskiy 1986, p. 44.

- ^ Windholz 1976.

- ^ Zýka 1966, p. 569.

- ^ Greenwood & Earnshaw 1998, p. 405.

- ^ a b c d e Lodders 2003, pp. 1220–47.

- ^ Roederer et al. 2009, pp. 1963–80.

- ^ a b c Burbidge et al. 1957, p. 547.

- ^ Frebel 2015, pp. 114–15.

- ^ a b c Davidson et al. 2014, p. 4.

- ^ Emsley 2011, pp. 286, passim.

- ^ Cox 1997, p. 182.

- ^ a b c United States Geological Survey 2016.

- ^ Rieuwerts 2015, p. 225.

- ^ Merriam-Webster.

- ^ Kroonen 2013, *lauda-.

- ^ Nikolayev 2012.

- ^ Kroonen 2013, *bliwa- 2.

- ^ Kroonen 2013, *laidijan-.

- ^ a b c d Hong et al. 1994, pp. 1841–43.

- ^ a b Rich 1994, p. 4.

- ^ a b c d e f Winder 1993b.

- ^ a b Rich 1994, p. 5.

- ^ a b History of Cosmetics.

- ^ Yu & Yu 2004, p. 26.

- ^ Toronto museum explores 2003.

- ^ Bisson & Vogel 2000, p. 105.

- ^ Eschnauer & Stoeppler 1992, pp. 58.

- ^ de Callataÿ 2005, pp. 361–72.

- ^ Settle & Patterson 1980, pp. 1170.

- ^ Rich 1994, p. 6.

- ^ Thornton, Rautiu & Brush 2001, pp. 179–84.

- ^ Bisel & Bisel 2002, pp. 459–60.

- ^ Retief & Cilliers 2006, pp. 149–51.

- ^ Grout 2017.

- ^ Hodge 1981, pp. 486–91.

- ^ Gilfillan 1965, pp. 53–60.

- ^ Nriagu 1983, pp. 660–63.

- ^ Frankenburg 2014, p. 16.

- ^ Scarborough 1984, pp. 469–75.

- ^ Waldron 1985, pp. 107–08.

- ^ Reddy & Braun 2010, pp. 1052–55.

- ^ Delile et al. 2014, pp. 6594–99.

- ^ Finger 2006, p. 184.

- ^ Lewis.

- ^ Thornton, Rautiu & Brush 2001, p. 183.

- ^ Polyanskiy 1986, p. 8.

- ^ Thomson 1830, p. 74.

- ^ Oxford English Dictionary, surma.

- ^ Vasmer 1950, сурьма.

- ^ Kellett 2012, pp. 106–07.

- ^ a b Winder 1993a.

- ^ a b c Rich 1994, p. 7.

- ^ Cotnoir 2006, p. 35.

- ^ Samson 1885, p. 388.

- ^ Sinha et al. 1993.

- ^ Ramage 1980, p. 8.

- ^ Gray 2013.

- ^ Nakashima, Matsuno & Matsushita 2007, pp. 134–39.

- ^ Nakashima et al. 1998, pp. 55–60.

- ^ Ashikari 2003, pp. 55–79.

- ^ Beard 1995, pp. 66.

- ^ Australian Mining History.

- ^ Bisson & Vogel 2000, p. 85.

- ^ a b Bisson & Vogel 2000, pp. 131–32.

- ^ Lead mining.

- ^ Sohn.

- ^ Rich 1994, p. 11.

- ^ a b c d Riva et al. 2012, pp. 11–16.

- ^ Hernberg 2000, pp. 246.

- ^ Why use lead.

- ^ Markowitz & Rosner 2000, pp. 36–46.

- ^ Rich 1994, p. 117.

- ^ Rich 1994, p. 17.

- ^ Rich 1994, pp. 91–92.

- ^ United States Geological Survey 2005.

- ^ Zhang et al. 2012, pp. 2261–73.

- ^ Significant growth in 2014.

- ^ Guberman 2015.

- ^ Graedel 2010.

- ^ a b c Thornton, Rautiu & Brush 2001, p. 56.

- ^ a b Davidson et al. 2014, p. 6.

- ^ a b c Davidson et al. 2014, p. 17.

- ^ Thornton, Rautiu & Brush 2001, p. 51.

- ^ Davidson et al. 2014, p. 11.

- ^ Thornton, Rautiu & Brush 2001, pp. 51–52.

- ^ Primary Extraction.

- ^ Davidson et al. 2014, p. 25.

- ^ a b c d Primary Lead Refining.

- ^ Pauling 1947.

- ^ Davidson et al. 2014, p. 34.

- ^ a b Thornton, Rautiu & Brush 2001, pp. 52–53.

- ^ a b Thornton, Rautiu & Brush 2001, p. 57.

- ^ Street & Alexander 1998, p. 181.

- ^ Evans 1908, pp. 133–79.

- ^ Baird & Cann 2012, pp. 537–38, 543–47.

- ^ About Us 2010.

- ^ Bastasch 2015.

- ^ Parker 2005, pp. 194–95.

- ^ Krestovnikoff & Halls 2006, p. 70.

- ^ Street & Alexander 1998, p. 182.

- ^ Jensen 2013, p. 136.

- ^ How does lead absorb radiation.

- ^ Tuček, Carlsson & Wider 2006, p. 1590.

- ^ Copper Development Association.

- ^ Guruswamy 2000, p. 31.

- ^ Lansdown & Yule 1986, p. 240.

- ^ Audsley 1965, pp. 250–51.

- ^ Palmieri 2006, pp. 412–13.

- ^ Think Lead research.

- ^ Weatherings to Parapets.

- ^ Lead garden ornaments 2016.

- ^ Putnam 2003, p. 216.

- ^ U.S. Geological Survey 2016, p. 97.

- ^ Progressive Dynamics, Inc.

- ^ State & Federal Energy.

- ^ Grid Services.

- ^ Leonard & Lynch 1958, pp. 414–16.

- ^ Burleson 2001, pp. 23.

- ^ Zweifel 2009, p. 438.

- ^ Wilkes et al. 2005, p. 106.

- ^ Randerson 2002.

- ^ Nriagu & Kim 2000, pp. 37–41.

- ^ Amstock 1997, pp. 116–19.

- ^ Rogalski 2010, pp. 485–541.

- ^ Emsley 2011, p. 280.

- ^ World Health Organization 2000, pp. 149–53.

- ^ Emsley 2011, p. 280, 621, 255.

- ^ a b Venugopal 2013, pp. 177–78.

- ^ Toxic Substances Portal.

- ^ U.S. Food and Drug Administration 2015, p. 41.

- ^ The National Institute for Occupational Safety and Health.

- ^ Bergeson 2008, pp. 79–84.

- ^ a b Rudolph et al. 2003, p. 369.

- ^ Dart, Hurlbut & Boyer-Hassen 2004, p. 1426.

- ^ Kosnett 2006, p. 238.

- ^ Sokol 2005, p. 153.

- ^ Mycyk, Hryhorczuk & Amitai 2005, p. 462.

- ^ Liu & Liu 2015, pp. 1869–74.

- ^ Schoeters et al. 2008, pp. 168–75.

- ^ Casciani 2014.

- ^ Gottschlich 2001, p. 98.

- ^ Insel, Turner & Ross 2004, p. 499.

- ^ Berdanier, Dwyer & Heber 2016, p. 224.

- ^ Hunter 2008, pp. 15–18.

- ^ Prasad 2010, pp. 651–52.

- ^ Masters, Trevor & Katzung 2008, pp. 481–83.

- ^ Toxfaqs: CABS/Chemical Agent 2006.

- ^ Information for Community.

- ^ Moore 1977, pp. 109–15.

- ^ Tarragó 2012, p. 11.

- ^ Niosh Adult Blood.

- ^ Radiation Your Health 2015.

- ^ Tarragó 2012, p. 16.

- ^ Wani, Ara & Usman 2015, pp. 57, 58.

- ^ a b Trace element emission 2012.

- ^ United Nations Environment Programme 2010, pp. 11–33.

- ^ Smith & Flegal 1995, pp. 21–23.

- ^ Deltares & Netherlands Organisation for Applied Scientific Research 2016.

- ^ Grandjean 1978, pp. 303–21.

- ^ a b Levin et al. 2008, p. 1288.

- ^ Duda 1996, p. 242.

- ^ Marino et al. 1990, pp. 1183–85.

- ^ Schoch 1996, p. 111.

- ^ Regulatory Status of 2000.

- ^ Lead in Waste 2016.

- ^ Freeman 2012, pp. a20–a21.

- ^ Young 2012.

- ^ Bairagi et al. 2011, p. 756.

- ^ Park et al. 2011, pp. 162–74.

Bibliography

- Alsfasser, R. (2007). Moderne anorganische Chemie [Modern inorganic chemistry] (in German). Walter de Gruyter. ISBN 978-3-11-019060-1.

- Amstock, J. S. (1997). Handbook of Glass in Construction. McGraw-Hill Professional. ISBN 978-0-07-001619-4.

- Anderson, J. (1869). "Malleability and ductility of metals". Scientific American. 21 (22): 341–43. .

- Ashikari, M. (2003). "The memory of the women's white faces: Japaneseness and the ideal image of women". Japan Forum. 15: 55–79. S2CID 144510689.

- Audsley, G. A. (1965). The Art of Organ Building. Vol. 2. Courier. ISBN 978-0-486-21315-6.

- Australian Mining History Association. "Mining History". www.mininghistory.asn.au. Retrieved 15 February 2016.

- Bairagi, H.; Khan, M.; Ray, L.; et al. (2011). "Adsorption profile of lead on Aspergillus versicolor: A mechanistic probing". Journal of Hazardous Materials. 186 (1): 756–64. PMID 21159429.

- Baird, C.; Cann, N. (2012). Environmental Chemistry (5th ed.). W. H. Freeman and Company. ISBN 978-1-4292-7704-4.

- Bastasch, M. (2015). "California officially bans hunters from using lead bullets". The Daily Caller. Retrieved 4 July 2016.

- Beard, M. E. (1995). Lead in Paint, Soil, and Dust: Health Risks, Exposure Studies, Control Measures, Measurement Methods, and Quality Assurance. ASTM International. ISBN 978-0-8031-1884-3.

- Becker, M.; Förster, C.; Franzen, C.; et al. (2008). "Persistent radicals of trivalent tin and lead". Inorganic Chemistry. 47 (21): 9965–78. PMID 18823115.

- Beeman, J. W.; Bellini, F.; Cardani, L.; et al. (2013). "New experimental limits on the α decays of lead isotopes". The European Physical Journal A. Vol. 49, no. 50. . Retrieved 21 August 2016.

- Berdanier, C. D.; Dwyer, J. T.; Heber, D. (2016). Handbook of Nutrition and Food (3rd ed.). CRC Press. ISBN 978-1-4665-0572-8. Retrieved 3 July 2016.

- Bergeson, Lynn L. (2008). "The proposed lead NAAQS: Is consideration of cost in the clean air act's future?". Environmental Quality Management. 18: 79–84. .

- Bisel, S. C.; Bisel, J. F. (2002). "Health and nutrition at Herculaneum". In Jashemski, W. F.; Meyer, F. G. (eds.). The Natural History of Pompeii. ISBN 978-0-521-80054-9.

- Bisson, M. S.; Vogel, J. O. (2000). Ancient African Metallurgy: The Sociocultural Context. Rowman & Littlefield. ISBN 978-0-7425-0261-1.

- Blakemore, J. S. (1985). Solid State Physics. Cambridge University Press. ISBN 978-0-521-31391-9.

- Boltwood, B. B. (1907). "On the ultimate disintegration products of the radio-active elements. Part II. The disintegration products of uranium". American Journal of Science. 23: 77–88. S2CID 131688682.

- Bremholm, M.; Hor, Y. S.; Cava, R. J. (2011). "Pressure stabilized Se–Se dimer formation in PbSe2". Solid State Sciences. 13 (1): 38–41. .

- Burleson, Mark (2001). The Ceramic Glaze Handbook: Materials, Techniques, Formulas. New York, NY: Sterling. ISBN 9781579904395.

- Burbidge, E. M.; Burbidge, G. R.; Fowler, W. A.; et al. (1957). "Synthesis of the Elements in Stars" (PDF). .

- de Callataÿ, F. (2005). "The Graeco-Roman economy in the super long-run: Lead, copper, and shipwrecks". Journal of Roman Archaeology. 18: 361–72. S2CID 232346123.

- Casciani, D. (2014). "Did removing lead from petrol spark a decline in crime?". BBC News. Retrieved 2017-01-30.

- Charles, J.; Kopf, P. W.; Toby, S. (1966). "The reaction of pyrophoric lead with oxygen". Journal of Physical Chemistry. 70 (5): 1478–82. .

- Chia, S.-P.; Xi, H.-W.; Li, Y.; et al. (2013). "A base-stabilized lead(I) dimer and an aromatic plumbylidenide anion". PMID 23629949.

- Christensen, N. E. (2002). "Relativistic Solid State Theory". In Schwerdtfeger, P. (ed.). Relativistic Electronic Structure Theory — Fundamentals. Elsevier. pp. 867–68. ISBN 978-0-08-054046-7.

- Copper Development Association. "Leaded Coppers". copper.org. Retrieved 10 July 2016.

- Cotnoir, B. (2006). The Weiser Concise Guide to Alchemy. Weiser Books. ISBN 978-1-57863-379-1.

- Cox, P. A. (1997). The Elements: Their Origin, Abundance and distribution. Oxford University Press. ISBN 0-19-855298-X.

- Dart, R. C.; Hurlbut, K. M.; Boyer-Hassen, L. V. (2004). "Lead". In Dart, R. C. (ed.). Medical Toxicology (3rd ed.). Lippincott Williams & Wilkins. p. 1426. ISBN 0-7817-2845-2.

- Delile, H.; Blichert-Toft, J.; Goiran, J.-P.; et al. (2014). "Lead in ancient Rome's city waters". Proceedings of the National Academy of Sciences. 111 (18): 6594–99. PMID 24753588.

- Deltares; Netherlands Organisation for Applied Scientific Research (2016). Lood en zinkemissies door jacht [Lead and zinc emissions from hunting] (PDF) (Report) (in Dutch). Retrieved 18 February 2017.

- Duda, M. B. (1996). Traditional Chinese Toggles: Counterweights and Charms. Editions Didier Millet. ISBN 978-981-4260-61-9.

- Emsley, J. (2011). Nature's Building Blocks: An A-Z Guide to the Elements. Oxford University. ISBN 978-0-19-850341-5.

- Ensafi, A. A.; Far, A. K.; Meghdadi, S. (2009). "Highly selective optical-sensing film for lead(II) determination in water samples". Journal of Hazardous Materials. 172 (2–3): 1069–75. PMID 19709813.

- Eschnauer, H. R.; Stoeppler, M. (1992). "Wine—An enological specimen bank". In Stoeppler, M. (ed.). Hazardous Materials in the Environment. Elsevier Science. pp. 49–72 (58). ISBN 0-444-89078-5.

- Evans, J. W. (1908). "V.— The meanings and synonyms of plumbago". Transactions of the Philological Society. 26 (2): 133–79. .

- Finger, Stanley (2006). Doctor Franklin's Medicine. University of Pennsylvania Press, Incorporated. ISBN 978-0-8122-3913-3.

- Fiorini, E. (2010). "2.000 years-old Roman Lead for physics" (PDF). ASPERA: 7–8. Retrieved 29 October 2016.

{{cite journal}}: Cite journal requires|journal=(help) - Frankenburg, F. R. (2014). Brain-Robbers: How Alcohol, Cocaine, Nicotine, and Opiates Have Changed Human History. ABC-CLIO. ISBN 978-1-4408-2932-1.

- Frebel, A. (2015). Searching for the Oldest Stars: Ancient Relics from the Early Universe. Princeton University. ISBN 978-0-691-16506-6.

- Freeman, K. S. (2012). "Remediating soil lead with fishbones". Environmental Health Perspectives. 120 (1): a20–a21. PMID 22214821.

- Gale, W. F.; Totemeier, T. C. (2003). Smithells Metals Reference Book. Butterworth-Heinemann. ISBN 978-0-08-048096-1.

- Gilfillan, S. C. (1965). "Lead poisoning and the fall of Rome". Journal of Occupational Medicine. 7 (2): 53–60. PMID 14261844.

- Gottschlich, M. M. (2001). The Science and Practice of Nutrition Support: A Case-based Core Curriculum. Kendall Hunt. ISBN 978-0-7872-7680-5. Retrieved 9 July 2016.

- Graedel, T. E.; et al. (2010). "Metal stocks in Society – Scientific Synthesis" (PDF). International Resource Panel. Retrieved 24 February 2017.

- Grandjean, P. (1978). "Widening perspectives of lead toxicity". Environmental Research. 17 (2): 303–21. PMID 400972.

- Gray, R. (2013). "Mary Rose reveals armour piercing cannonball secret". The Telegraph. Retrieved 28 February 2017.

- Greene, D. (2014). "Effects of lead on the environment". lead.org.au. Retrieved 30 October 2016.

- Greenwood, N. N.; Earnshaw, A. (1998). Chemistry of the Elements (2nd ed.). Butterworth Heinemann. ISBN 0-7506-3365-4.

- "Grid Services". Ecoult Energy Storage Solutions. Retrieved 28 February 2017.

- Grout, J. (2017). "Lead poisoning and Rome". Encyclopaedia Romana. Retrieved 15 February 2017.

- Guberman, D. E. (2015). "Lead" (PDF). 2013 Minerals Yearbook (Report). United States Geological Survey. Retrieved 2 November 2016.

- Guruswamy, S. (2000). Engineering properties and applications of lead alloys. Marcel Dekker. ISBN 978-0-8247-8247-4.

- Harbison, R. D.; Bourgeois, M. M.; Johnson, G. T. (2015). Hamilton and Hardy's Industrial Toxicology. John Wiley & Sons. ISBN 978-0-470-92973-5.

- Hernberg, S. (2000). "Lead Poisoning in a Historical Perspective" (PDF). American Journal of Industrial Medicine Reports. 38 (3): 244–54. PMID 10940962. Retrieved 1 March 2017.

- "A History of Cosmetics from Ancient Times". Cosmetics Info. Retrieved 18 July 2016.

- Hodge, T. A. (1981). "Vitruvius, lead pipes and lead poisoning". American Journal of Archaeology. 85 (4). Archaeological Institute of America: 486–91. S2CID 193094209.

- Hong, S.; Candelone, J.-P.; Patterson, C. C.; et al. (1994). "Greenland ice evidence of hemispheric lead pollution two millennia ago by Greek and Roman civilizations" (PDF). Science. 265 (5180): 1841–43. S2CID 45080402.

- "How does lead absorb radiation like x-rays and gamma rays?". The Naked Scientists. 2009. Retrieved 31 March 2017.

- Hunter, P. (2008). "A toxic brew we cannot live without. Micronutrients give insights into the interplay between geochemistry and evolutionary biology". EMBO Reports. 9 (1): 15–18. PMID 18174893.

- "Information for the Community Lead Toxicity". Agency for Toxic Substances and Disease Registry (MP4 webcast, 82 MB). Retrieved 11 February 2017.

- Insel, P. M.; Turner, R. E.; Ross, D. (2004). Nutrition. Jones & Bartlett Learning. ISBN 978-0-7637-0765-1. Retrieved 10 July 2016.

- Jensen, C. F. (2013). Online Location of Faults on AC Cables in Underground Transmission. Springer. ISBN 978-3-319-05397-4.

- Jones, P. A. (2014). "Lead balloon". Jedburgh Justice and Kentish Fire: The Origins of English in Ten Phrases and Expressions. Constable. ISBN 978-1-4721-1622-2.

- Kaupp, M. (2014). "Chemical bonding of main-group elements". In Frenking, G.; Shaik, S. (eds.). The Chemical Bond: Chemical Bonding Across the Periodic Table (PDF). ISBN 9783527664658.

- Kellett, C. (2012). Poison and Poisoning: A Compendium of Cases, Catastrophes and Crimes. Accent Press. ISBN 978-1-909335-05-9.

- King, R. B. (1995). Inorganic Chemistry of Main Group Elements. ISBN 978-0-471-18602-1.

- Klatt, E. C. "Firearms Tutorial". library.med.utah.edu. Retrieved 5 February 2017.

- Koshal, D. (2014). Manufacturing Engineer's Reference Book. Butterworth-Heinemann. ISBN 978-0-08-052395-8.

- Kosnett, M. J. (2006). "Lead". In Olson, K. R. (ed.). Poisoning and Drug Overdose (5th ed.). McGraw-Hill Professional. p. 238. ISBN 978-0-07-144333-3.

- Krestovnikoff, M.; Halls, M. (2006). Scuba Diving. Penguin. ISBN 978-0-7566-4063-7.

- Kroonen, G. (2013). Etymological Dictionary of Proto-Germanic. Leiden Indo-European Etymological Dictionary Series. Brill. ISBN 978-90-04-18340-7.

- Lansdown, R.; Yule, William, eds. (1986). The Lead debate : the environment, toxicology, and child health. Croom Helm. ISBN 978-0-7099-1653-6.)

{{cite book}}: CS1 maint: ref duplicates default (link - "Lead Paint Information". Master Painters Australia. Archived from the original on 12 February 2008. Retrieved 2 March 2017.

- "Lead garden ornaments". H. Crowther Ltd. 2016. Retrieved 20 February 2017.

- "Lead in Waste Disposal". United States Environmental Protection Agency. 2016. Retrieved 28 February 2017.

- "Lead mining". The Northern Echo. Retrieved 16 February 2016.

- Leonard, A. R.; Lynch, G. (1958). "Dishware as a possible source for lead poisoning". PMID 13608300.

- Levin, R.; Brown, M. J.; Kashtock, M. E.; et al. (2008). "Lead exposures in U.S. children, 2008: Implications for prevention". Environmental Health Perspectives. 116 (10): 1285–93. PMID 18941567.

- Lewis, J. "Lead Poisoning: A Historical Perspective". United States Environmental Protection Agency. Retrieved 31 January 2017.

- Lide, D. R., ed. (2004). CRC Handbook of Chemistry and Physics (84th ed.). CRC Press. ISBN 978-0-8493-0484-2.

- "Livechart - Table of Nuclides - Nuclear structure and decay data". www-nds.iaea.org. International Atomic Energy Agency. 2017. Retrieved 31 March 2017.

- Liu, J.; et al. (2015). "Early blood lead levels and sleep disturbance in preadolescence". PMID 26194570.

- Lodders, K. (2003). "Solar System abundances and condensation temperatures of the elements". The Astrophysical Journal. 591 (2): 1220–47. ISSN 0004-637X.

- Macomber, R. S. (1996). Organic Chemistry. University Science Books. ISBN 978-0-935702-90-3.

- Marcillac, P. de; Coron, N.; Dambier, G.; et al. (2003). "Experimental detection of α-particles from the radioactive decay of natural bismuth". Nature. 422 (6934): 876–78. S2CID 4415582.

- Marino, P. E.; Landrigan, P. J.; Graef, J.; et al. (1990). "A case report of lead paint poisoning during renovation of a Victorian farmhouse". American Journal of Public Health. 80 (10): 1183–85. PMID 2119148.

- Markowitz, G.; Rosner, D. (2000). ""Cater to the children": the role of the lead industry in a public health tragedy, 1900–55". PMID 10630135.

- Masters, S. B.; Trevor, A. J.; Katzung, B. G. (2008). Katzung & Trevor's Pharmacology: Examination & Board Review (8th ed.). ISBN 978-0-07-148869-3.

- Meija, J.; Coplen, T. B.; Berglund, M.; et al. (2016). "Atomic weights of the elements 2013 (IUPAC Technical Report)". Pure and Applied Chemistry. 88 (3): 265–291. S2CID 101719914.

- Merriam-Webster. "Definition of LEAD". www.merriam-webster.com. Retrieved 12 August 2016.

- Moore, M. R. (1977). "Lead in drinking water in soft water areas—health hazards". Science of the Total Environment. 7 (2): 109–15. PMID 841299.

- Mosseri, S.; Henglein, A.; Janata, E. (1990). "Trivalent lead as an intermediate in the oxidation of lead(II) and the reduction of lead(IV) species". The Journal of Physical Chemistry. 94 (6): 2722–26. .

- Mycyk, M.; Hryhorczuk, D.; Amitai, Y.; et al. (2005). "Lead". In Erickson, T. B.; Ahrens, W. R.; Aks, S. (eds.). Pediatric Toxicology: Diagnosis and Management of the Poisoned Child. McGraw-Hill Professional. ISBN 978-0-07-141736-5.

- Nakashima, T.; Hayashi, H.; Tashiro, H.; et al. (1998). "Gender and hierarchical differences in lead-contaminated Japanese bone from the Edo period". Journal of Occupational Health. 40: 55–60. S2CID 71451911.

- Nakashima, T.; Matsuno, K.; Matsushita, T. (2007). "Lifestyle-determined gender and hierarchical differences in the lead contamination of bones from a feudal town of the Edo period". S2CID 32511300.

- ISBN 978-0-929600-83-3.

- Nikolayev, S., ed. (2012). "*lAudh-". Indo-European Etymology. Retrieved 21 August 2016.

{{cite book}}:|website=ignored (help)CS1 maint: ref duplicates default (link) - "NIOSH Adult Blood Lead Epidemiology and Surveillance". United States National Institute for Occupational Safety and Health. Retrieved 2 March 2017.

- Norman, N. C. (1996). Periodicity and the s- and p-Block Elements. Oxford University Press. ISBN 978-0-19-855961-0.

- Nosengo, N. (2010). "Roman ingots to shield particle detector". Nature News. .

- Nriagu, J. O. (1983). "Saturnine gout among Roman aristocrats". New England Journal of Medicine. 308 (11): 660–63. PMID 6338384.

- Nriagu, J.; Kim, M. J. (2000). "Emissions of lead and zinc from candles with metal-core wicks". The Science of the Total Environment. 250 (1–3): 37–41. PMID 10811249.

- "Nuclear Radiation and Health Effects". World Nuclear Association. 2015. Retrieved 12 November 2015.

- Palmieri, R., ed. (2006). The Organ. Garland. ISBN 978-0-415-94174-7.)

{{cite book}}: CS1 maint: ref duplicates default (link - "surma". Oxford English Dictionary (2nd ed.). Oxford University Press. 2009.

- Parker, R. B. (2005). The New Cold-Molded Boatbuilding: From Lofting to Launching. WoodenBoat Books. ISBN 978-0-937822-89-0.

- Park, J. H.; Bolan, N.; Meghara, M.; et al. (2011). "Bacterial-assisted immobilization of lead in soils: Implications for remediation" (PDF). Pedologist: 162–74. Archived from the original (PDF) on 26 November 2015.

- ISBN 978-0-486-65622-9.

- Polyanskiy, N. G. (1986). Fillipova, N. A (ed.). Аналитическая химия элементов: Свинец [Analytical Chemistry of the Elements: Lead] (in Russian). Nauka.

- Prasad, P. J. (2010). Conceptual Pharmacology. Universities Press. ISBN 978-81-7371-679-9. Retrieved 21 June 2012.

- "Primary Extraction of Lead Technical Notes". LDA International. Archived from the original on 22 March 2007. Retrieved 7 April 2007.

- "Primary Lead Refining Technical Notes". LDA International. Archived from the original on 22 March 2007. Retrieved 7 April 2007.

- Progressive Dynamics, Inc. "How Lead Acid Batteries Work: Battery Basics". progressivedyn.com. Retrieved 3 July 2016.

- Putnam, B. (2003). The Sculptor's Way: A Guide to Modelling and Sculpture. Dover Publications. ISBN 978-0-486-42313-5.

- .

- "Radiation and Your Health". Centers for Disease Control and Prevention. 7 December 2015. Retrieved 28 February 2017.

- Ramage, C. K. (1980). Lyman Cast Bullet Handbook (3rd ed.). Lyman Publications.

- Randerson, J. (2002). "Candle pollution". newscientist.com (2348). Retrieved 7 April 2007.

- Rappoport, Z.; Marek, I. (2010). The Chemistry of Organocopper Compounds. John Wiley & Sons. ISBN 978-0-470-77296-6.

- Reddy, A.; Braun, C. L. (2010). "Lead and the Romans". Journal of Chemical Education. 87 (10): 1052–55. ISSN 0021-9584.

- "Regulatory Status of Waste Generated by Contractors and Residents from Lead-Based Paint Activities Conducted in Households". United States Environmental Protection Agency. 2000. Retrieved 28 February 2017.

- Retief, F.; Cilliers, L. P. (2006). "Lead poisoning in ancient Rome". Acta Theologica. 26 (2): 147–64 (149–51). .

- Rich, V. (1994). The International Lead Trade. Woodhead Publishing. ISBN 978-1-85573-103-5.

- Rieuwerts, J. (2015). The Elements of Environmental Pollution. Routledge. ISBN 978-0-415-85919-6.

- Riva, M. A.; Lafranconi, A.; d'Orso, M. I.; et al. (2012). "Lead poisoning: Historical aspects of a paradigmatic "occupational and environmental disease"". Safety and Health at Work. 3 (1): 11–16. PMID 22953225.

- Roederer, I. U.; Kratz, K.-L.; Frebel, A.; et al. (2009). "The end of nucleosynthesis: Production of lead and thorium in the early galaxy". The Astrophysical Journal. 698 (2). The American Astronomical Society: 1963–80. S2CID 14814446. Retrieved 18 July 2016.

- Rogalski, A. (2010). Infrared Detectors, Second Edition. CRC Press. ISBN 978-1-4200-7672-1. Retrieved 19 November 2016.

- Rudolph, A. M.; Rudolph, C. D.; Hostetter, M. K.; et al. (2003). "Lead". Rudolph's Pediatrics (21st ed.). McGraw-Hill Professional. p. 369. ISBN 978-0-8385-8285-5.

- Röhr, C. "Binäre Zintl-Phasen" [Binary Zintl Phases] (in German). Universität Freiburg. Retrieved 18 February 2017.

- Samson, G. W. (1885). The divine law as to wines. J. B. Lippincott & Co.

- Scarborough, J. (1984). "The myth of lead poisoning among the Romans: An essay review". Journal of the History of Medicine and Allied Sciences. 39 (4): 469–475. PMID 6389691.

- Schoch, R. M. (1996). Case Studies in Environmental Science. West Publishing. ISBN 0-314-20397-4.

- Schoeters, G.; Den Hond, E.; Dhooge, W.; et al. (2008). "Endocrine disruptors and abnormalities of pubertal development". Basic & Clinical Pharmacology & Toxicology. 102 (2): 168–175. PMID 18226071.

- Settle, D. M.; Patterson, C. C. (1980). "Lead in Albacore: Guide to Lead Pollution in Americans". Science. 207 (4436): 1167–76. PMID 6986654.

- Sharma, H. R; Nozawa, K.; Smerdon, J. A.; et al. (2013). "Templated three-dimensional growth of quasicrystalline lead". Nature Communications. 4: 2715. PMID 24185350.

- Sharma, H. R.; Smerdon, J. A.; Nugent, P. J.; et al. (2014). "Crystalline and quasicrystalline allotropes of Pb formed on the fivefold surface of icosahedral Ag-In-Yb". The Journal of Chemical Physics. 140 (17): 174710. PMID 24811658.

- "Significant growth in lead usage underlines its importance to the global economy". International Lead Association. 2014. Retrieved 28 February 2017.

Global demand for lead has more than doubled since the early 1990s and almost 90% of use is now in lead-acid batteries

- Silverman, M. S. (1966). "High-pressure (70-kilobar) synthesis of new crystalline lead dichalcogenides". .

- Sinha, S. P.; Shelly; Sharma, V.; et al. (1993). "Neurotoxic effects of lead exposure among printing press workers". Bulletin of Environmental Contamination and Toxicology. 51 (4): 490–493. S2CID 26631583.

- Smirnov, A. Yu.; Borisevich, V. D.; Sulaberidze, A. (2012). "Evaluation of specific cost of obtainment of lead-208 isotope by gas centrifuges using various raw materials". Theoretical Foundations of Chemical Engineering. 46 (4): 373–78. S2CID 98821122.

- Smith, D. R.; Flegal, A. R. (1995). "Lead in the biosphere: Recent trends". JSTOR 4314280.

- Sohn, E. "Lead: Versatile Metal, Long Legacy". Dartmouth Toxic Metals Superfund Research Program. Retrieved 16 February 2016.

- Sokol, R. C. (2005). "Summary". In Golub, M. S. (ed.). Metals, Fertility, and Reproductive Toxicity. Taylor and Francis. p. 153. ISBN 978-0-415-70040-5.

- Stabenow, F.; Saak, W.; Weidenbruch, M. (2003). "Tris(triphenylplumbyl)plumbate: An anion with three stretched lead–lead bonds". Chemical Communications (18): 2342–2343. PMID 14518905.

- "State & Federal Energy Storage Technology Advancement Partnership (ESTAP)" (PDF). Clean Energy States Alliance. Retrieved 28 February 2017.

- Street, A.; Alexander, W. (1998). Metals in the Service of Man. Penguin Books. ISBN 978-0-14-025776-2.

- Davidson, A.; Ryman, J.; Sutherland, C. A.; et al. (2014). "Lead". Ullmann's Encyclopedia of Industrial Chemistry. ISBN 978-3-527-30673-2.

- Takahashi, K.; Boyd, R. N.; Mathews, G. J.; et al. (1987). "Bound-state beta decay of highly ionized atoms" (PDF). Physical Review C. 36 (4). PMID 9954244. Archived from the original(PDF) on 21 October 2014. Retrieved 27 August 2013.

- Tarragó, A. (2012). "Case Studies in Environmental Medicine (CSEM) Lead Toxicity" (PDF). Agency for Toxic Substances and Disease Registry.

- The National Institute for Occupational Safety and Health. "CDC – NIOSH Pocket Guide to Chemical Hazards — Lead". www.cdc.gov. Retrieved 18 November 2016.

- "Think Lead research summary" (PDF). The Lead Sheet Association. Retrieved 20 February 2017.

- Thomson, T. (1830). The History of Chemistry. Henry Colburn and Richard Bentley (publishers).

- Thornton, I.; Rautiu, R.; Brush, S. M. (2001). Lead: The Facts (PDF). International Lead Association. ISBN 978-0-9542496-0-1. Retrieved 5 February 2017.

- Thurmer, K.; Williams, E.; Reutt-Robey, J. (2002). "Autocatalytic oxidation of lead crystallite surfaces". Science. 297 (5589): 2033–35. PMID 12242437.

- "Toronto museum explores history of contraceptives". ABC News. 2003. Retrieved 13 February 2016.

- "ToxFAQs: CABS/Chemical Agent Briefing Sheet: Lead" (PDF). Agency for Toxic Substances and Disease Registry/Division of Toxicology and Environmental Medicine. 2006. Archived from the original (PDF) on 4 March 2010.

- "Toxic Substances Portal – Lead". Agency for Toxic Substance and Disease Registry. Archived from the original on 6 June 2011.

- "Trace element emission from coal". IEA Clean Coal Centre. 2012. Retrieved 1 March 2017.

- Tuček, K.; Carlsson, J.; Wider, H. (2006). "Comparison of sodium and lead-cooled fast reactors regarding reactor physics aspects, severe safety and economical issues" (PDF). Nuclear Engineering and Design. 236 (14–16): 1589–98. .

- Tétreault, J.; Sirois, J.; Stamatopoulou, E. (1998). "Studies of lead corrosion in acetic acid environments". Studies in Conservation. 43 (1): 17–32. JSTOR 1506633.

- U.S. Food and Drug Administration (2015). Q3D Elemental Impurities Guidance for Industry (PDF) (Report). U. S. Department of Health and Human Services. p. 41. Retrieved 15 February 2017.)

{{cite report}}: Cite has empty unknown parameter:|authors=(help - U.S. Geological Survey (2016). "Lead" (PDF). Mineral Commodities Summaries. p. 97. Retrieved 20 February 2017.

- United Nations Environment Programme (2010). Final review of scientific information on lead (PDF). Chemicals Branch, Division of Technology, Industry and Economics. Retrieved 31 January 2017.

- United States Geological Survey (2005). Lead (PDF) (Report). Retrieved 20 February 2016.

- United States Geological Survey (2016). Lead (PDF) (Report). Retrieved 20 February 2016.

- University of California Berkeley Nuclear Forensic Search Project. "Decay Chains". Nuclear Forensics: A Scientific Search Problem. Retrieved 23 November 2015.

- Vasmer, M. (1986–1987) [1950–1958]. Trubachyov, O. N.; Larin, B. O. (eds.). Этимологический словарь русского языка [Russisches etymologisches Wörterbuch] (in Russian) (2nd ed.). Progress. Retrieved 4 March 2017.

- Venugopal, B. (2013). Physiologic and Chemical Basis for Metal Toxicity. Springer. ISBN 978-1-4684-2952-7.

- Vogel, N. A.; Achilles, R. (2013). The Preservation and Repair of Historic Stained and Leaded Glass (PDF) (Report). United States Department of the Interior. Retrieved 30 October 2016.

- Waldron, H. A. (1985). "Lead and lead poisoning in antiquity". Medical History. 29 (1): 107–08. PMC 1139494.

- Wani, A. L.; Ara, A.; Usman, J. A. (2015). "Lead toxicity: A review". Interdisciplinary Toxicology. 8 (2): 55–64. PMID 27486361.

- Weast, R. C.; Astle, M. J.; Beyer, W. H. (1983). CRC Handbook of Chemistry and Physics: A Ready-reference Book of Chemical and Physical Data. CRC Press. ISBN 978-0-8493-0464-4.

- "Weatherings to Parapets and Cornices". The Lead Sheet Association. Retrieved 20 February 2017.

- Webb, G. W.; Marsiglio, F.; Hirsch, J. E. (2015). "Superconductivity in the elements, alloys and simple compounds". Physica C: Superconductivity and Its Applications. 514: 17–27. S2CID 119290828.

- Whitten, K. W.; Gailey, K. D.; David, R. E. (1996). General chemistry with qualitative analysis (3rd ed.). Saunders College. ISBN 978-0-03-012864-6.

- "Why use lead in paint?". Chemistry World. Royal Society of Chemistry. Retrieved 22 February 2017.

- Wiberg, E.; Wiberg, N.; Holleman, A. F. (2001). Inorganic Chemistry. Academic Press. ISBN 978-0-12-352651-9.

- Wilkes, C. E.; Summers, J. W.; Daniels, C. A.; et al. (2005). PVC Handbook. Hanser. ISBN 978-1-56990-379-7.

- Willey, D. G. (1999). "The physics behind four amazing demonstrations — CSI". Skeptical Inquirer. 23 (6). Retrieved 6 September 2016.

- Winder, C. (1993a). "The history of lead — Part 1". LEAD Action News. 2 (1). The LEAD Group. ISSN 1324-6011. Archived from the originalon 31 August 2007. Retrieved 5 February 2016.

- Winder, C. (1993b). "The history of lead — Part 3". LEAD Action News. 2 (3). ISSN 1324-6011. Archived from the originalon 31 August 2007. Retrieved 12 February 2016.

- Windholz, M. (1976). ISBN 978-0-911910-26-1. Monograph 8393.

- World Health Organization (2000). "Lead". Air quality guidelines for Europe (PDF). Regional Office for Europe. pp. 149–53. OCLC 475274390.

- Yong, L.; Hoffmann, S. D.; Fässler, T. F. (2006). "A low-dimensional arrangement of [Pb9]4− clusters in [K(18-crown-6)]2K2Pb9·(en)1.5". Inorganica Chimica Acta. 359 (15). Elsevier: 4774–78. .

- Young, S. (9 July 2012). "Battling lead contamination, one fish bone at a time". Compass. United States Coast Guard. Retrieved 11 February 2017.

- Yu, L.; Yu, H. (2004). Chinese Coins: Money in History and Society. Long River Press. ISBN 978-1-59265-017-0.

- Zhang, X.; Yang, L.; Li, Y.; et al. (2012). "Impacts of lead/zinc mining and smelting on the environment and human health in China". Environmental Monitoring and Assessment. 184 (4): 2261–73. S2CID 20372810.

- Zuckerman, J. J.; Hagen, A. P. (1989). Inorganic Reactions and Methods, the Formation of Bonds to Halogens. John Wiley & Sons. ISBN 978-0-471-18656-4.

- Zweifel, H. (2009). Plastics Additives Handbook. Hanser. ISBN 978-3-446-40801-2.

- Zýka, J. (1966). "Analytical study of the basic properties of lead tetraacetate as oxidizing agent". Pure and Applied Chemistry. 13 (4): 569–81. S2CID 96821219. Retrieved 2 March 2017.

Further reading

- "About Us". thebulletworks.net. 2010. Retrieved 4 July 2016.

{{cite web}}: Cite has empty unknown parameter:|1=(help) - Casas, J. S.; Sordo, J., eds. (2006). Lead Chemistry, Analytical Aspects. Environmental Impacts and Health Effects. Elsevier. ISBN 978-0-444-52945-9.

- Cohen, Alan R.; Trotzky, Margret S.; Pincus, Diane (1981). "Reassessment of the Microcytic Anemia of Lead Poisoning". Pediatrics. 67 (6): 904–906. S2CID 42146120.

- Keisch, B. (1968). "Dating works of art through their natural radioactivity: Improvements and applications". Science. 160 (3826): 413–415. S2CID 38078513.

- Keisch, B. (1968). "Discriminating radioactivity measurements of lead: New tool for authentication". Curator. 11 (1): 41–52. .

- Keisch, B.; Feller, R. L.; Levine, A. S.; et al. (1967). "Dating and authenticating works of art by measurement of natural alpha emitters". Science. 155 (3767): 1238–1242. S2CID 23046304.

- Uekoetter, F. (2004). "The merits of the precautionary principle: Controlling automobile exhausts in Germany and United States before 1945". In Dupuis, E. M. (ed.). Smoke and Mirrors: The Politics and Culture of Air Pollution. New York University Press. p. 132. ISBN 0-8147-1960-0.